Introduction to Scara Robots in Manufacturing

The manufacturing business is a whole different story now that SCARA (Selective Compliance Assembly Robot Arm) robots are here, providing the factory floor with unparalleled precision, agility, and efficiency. A prime illustration of the latest advancements in robotics technology is the EVS20-800H Scara Robot, one of these robots. Designed with a compact and flexible structure, it excels in fast running speed and high transmission accuracy, significantly reducing noise levels. This robot is a flexible instrument in a range of production environments since it can handle intricate jobs including palletizing, assembly, and 3C sector operations.

Technical Advancements in Scara Robots

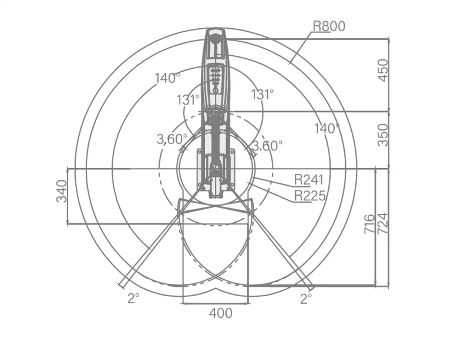

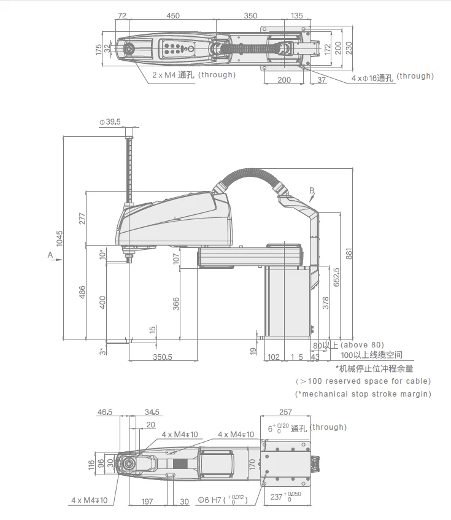

The EVS20-800H is a testament to the rapid advancements in the field of scara robots. It’s engineered with a sophisticated four-axis design, boasting an extensive reach of 800mm. This scara robot is tailored for efficiency, handling a rated payload of 10kg and a maximum of 20kg, which is impressive for its size. The technical prowess of the EVS20-800H extends beyond its payload capacity. It showcases remarkable precision with repeated positioning accuracy, having horizontal coordinates of ±0.025mm and a z-coordinate of ±0.01mm. Its axes can reach speeds up to 9940mm/s, demonstrating the robot’s capability to enhance productivity in fast-paced manufacturing environments. These features mark a significant leap in the capabilities of scara robots, emphasizing their critical role in modernizing manufacturing processes.

Scara Robots: Enhancing Precision and Speed

Beyond its technical specifications, the EVS20-800H Scara Robot aims to redefine the standards for speed and precision in manufacturing settings. Its design minimizes operational noise and its rigid structure guarantees stability and accuracy in every movement, making it appropriate for a variety of industrial settings. The robot’s speed is complemented by its precision, ensuring tasks are not only performed quickly but also with exactness, crucial for industries where error margins are incredibly tight. The broad operating range of the EVS20-800H, with axes capable of extensive movement, further enhances its applicability in diverse manufacturing scenarios, making it a valuable asset in the robotics in manufacturing sector.

Scara Robots in Diverse Manufacturing Applications

The application spectrum of the EVS20-800H Scara Robot is vast and diverse, extending its utility beyond traditional manufacturing tasks. Its remarkable speed and accuracy make it the ideal instrument for intricate jobs in the 3C industry, where parts are often delicate and require careful handling; its versatility boosts output and creates new opportunities for creative applications across a range of manufacturing domains; its compatibility with cutting-edge vision systems and smooth integration into ever-more-complex manufacturing procedures further enhance its functionality in robotics in manufacturing.

The Economic Impact of Implementing Scara Robots

Incorporating scara robots like the EVS20-800H into manufacturing processes goes beyond technical enhancement; it represents a strategic economic decision. The automation and efficiency brought by these robots significantly reduce the need for manual labor, leading to substantial cost savings in the long run. This shift in the manufacturing paradigm enhances productivity, ultimately contributing to a more robust bottom line. The deployment of scara robots in manufacturing sectors also aligns with broader trends in industrial automation, indicating a shift towards more cost-effective, efficient, and competitive production methodologies.

Future Prospects of Scara Robots in Manufacturing

The possibilities for scara robots in manufacturing are vast and promising; as the sector develops, so too will the robots’ uses and capabilities. New developments and continuous improvements will augment the functionality and effectiveness of robots such as the EVS20-800H. These developments will continue to shape the narrative of robotics in manufacturing, steering the industry towards a more automated, efficient, and innovative future.

Conclusion

Robots such as the EVS20-800H are not only instruments for task automation; they are forces behind a fundamental revolution in the manufacturing sector. Scara robots have a deep and wide-ranging impact on modern manufacturing, and EVS Int appreciate these technical breakthroughs that are leading to a change toward a more inventive, efficient, and environmentally friendly industrial environment.

Thanks to scara robots, manufacturing can now integrate strategic vision with technological innovation, leading to integrated production processes that prioritize accuracy, efficiency, and flexibility for the manufacturing sector. As a result, manufacturing is set to undergo a radical transformation. The opportunities in this dynamic environment will be endless, matching the robots’ capabilities and signaling the beginning of a new era of industrial productivity and inventiveness.