Source: dcvelocity.com

Warehouses are a mid-point in the supply chain. They handle goods that are in transit from manufacturers to customers or from person to person as is the case with parcels.

Between the receiving, storing, and dispatching of packages, running a warehouse is no mean feat. It requires a high level of organization and can be quite expensive given how labor-intensive it is. Unless of course, you invest in automation solutions to streamline operations.

Warehouse robots are increasingly becoming popular among a wide variety of businesses with warehouse departments. The question is are they worth it? Read on and let’s find out.

Table of Contents

What is a Robot Warehouse System?

Source: gebhardt-foerdertechnik.de

A robot warehouse system refers to the use of automated robots to handle goods and manage inventory in a warehouse. The robots used in such a system are known as warehouse robots. They are uniquely designed to manage the movement and handling of loads and are often compatible with warehouse software.

Types of Robot Warehouse Systems

Robot warehouse systems differ based on their features which subsequently determine their functions. They are categorized as below.

Autonomous Mobile Robots (AMRs)

Source: conveyco.com

Autonomous Mobile Robots are used to move inventory within a warehouse. Their motions are guided by a map of the warehouse installed into their computerized system. They also have sensors that help with navigation and avoiding collisions.

When it comes to handling inventory, AMRs can identify, sort, collect, and deliver requested packages to a warehouse employee. Models that are fitted with RFID sensors and scanners can also be applied for stock-taking. They can identify packages from a distance without an employee having to walk around the warehouse scanning each unit of inventory.

Automated Storage and Retrieval Systems(AS/RS)

Source: muratec-usa.com

When a customer makes an order at a warehouse, staff would ordinarily have to:

Retrieve the requested commodity from the inventory

Dispatch what the customer requested

Return what is left, if at all, to storage

It is a time-consuming process that can slow down service delivery and also require a lot of human labor to fulfill.

Automated Storage and Retrieval Systems are designed to handle all the steps listed above. They retrieve and return units of inventory to their designated areas as prompted. Employees can put in orders through warehouse management systems or via wifi as they are compatible with both. They also come in different designs depending on the application; there are shuttle models, cranes, and shelf-climbing robots.

Automated Guided Vehicles(AGVs)

Source: flexqube.com

AGVs cart inventory to and from different points in a warehouse. Most of them follow magnetic strips installed on the warehouse floor to guide their navigation. As a result, they can only follow a particular path. However, there are models with safety scanners that could be more flexible.

AGVs are best applied for inventory transportation as they do not have the capabilities to do more unless they are modified.

Aerial Drones

Source: p2pconnect.com

They are also known as Unmanned Aerial Vehicles and are quite a versatile option. Whereas they are used in many other fields, warehouse robot companies have begun developing them specifically for warehouses. They can be used to:

Locate packages using RFID inventory labels from afar

Perform real-time stock-taking

Transport small inventory packages

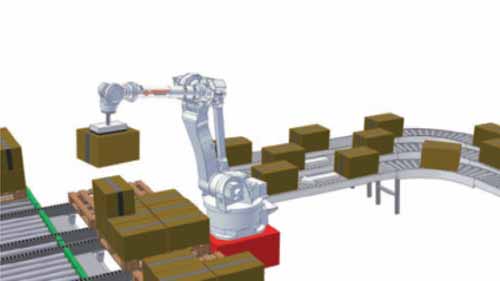

Articulated Robotic Arms

Articulated robotic arms are flexible robotic limbs that are highly efficient in pick and place as well as inventory sorting tasks. They are available in different payload capacities and you can choose between a 4-axis robot arm and a 6-axis robot arm. A variety of arm lengths also gives them a vertical advantage over most other robotic warehouse systems. Where necessary, they can be fitted with sensors or vision systems to ensure better accuracy during the handling of inventory.

Applications

Source: Pexels

Due to their distinct capabilities, different robot warehouse systems are suitable for different industries. Some industrial applications include:

E-commerce

E-commerce businesses like Alibaba and Amazon handle large volumes of merchandise of all kinds. In a bid to keep turnaround times short, they have incorporated robot warehouse systems.

Alibaba, for example, integrated Automated Guided Vehicles. They are used to deliver merchandise to warehouse staff for packaging and dispatch.

Logistics

The logistics industry is vast in that it includes parcel companies and larger shipment firms. They apply different robotic warehouse systems depending on their needs. Articulated robot arms, for instance, are common in shipment yards where they are used as cranes. Autonomous Mobile Robots are also popular among parcel companies.

Multi-industry Labelling

Placing labels on products whether food, beverages, or cosmetics is repetitive and requires precision. It would also require lots of hands to get it done in time. Manufacturers are thus shifting towards automated labeling using robotic arms which are faster, efficient, and low-cost.

Conclusion

There are certainly numerous advantages to investing in a robotic warehouse system. More so if you find a system that suits the needs of your warehouse and a reputable industrial robot manufacturer to work with.

Also Read: