Introduction

An ongoing shift towards more intelligent and effective systems is occurring in the dynamic realm of logistics. This transition, referred to as “smart logistics,” utilizes sophisticated technologies in order to optimize processes, increase openness, and decrease expenditures. Robotic systems, particularly six axis robots, are at the center of this revolution, driving the logistics industry towards an unprecedented level of efficacy. The 6 axis collaborative robot, which has a 1300mm reaching distance and a 12kg payload, stands out among these technological miracles as a beacon of innovation. The incredible dependability and performance that six axis robots bring to smart logistics operations are exemplified by this cobot, which is intended for duties spanning from handling and palletizing to pick and place and even arc welding.

Recognizing this Axis Six Robots

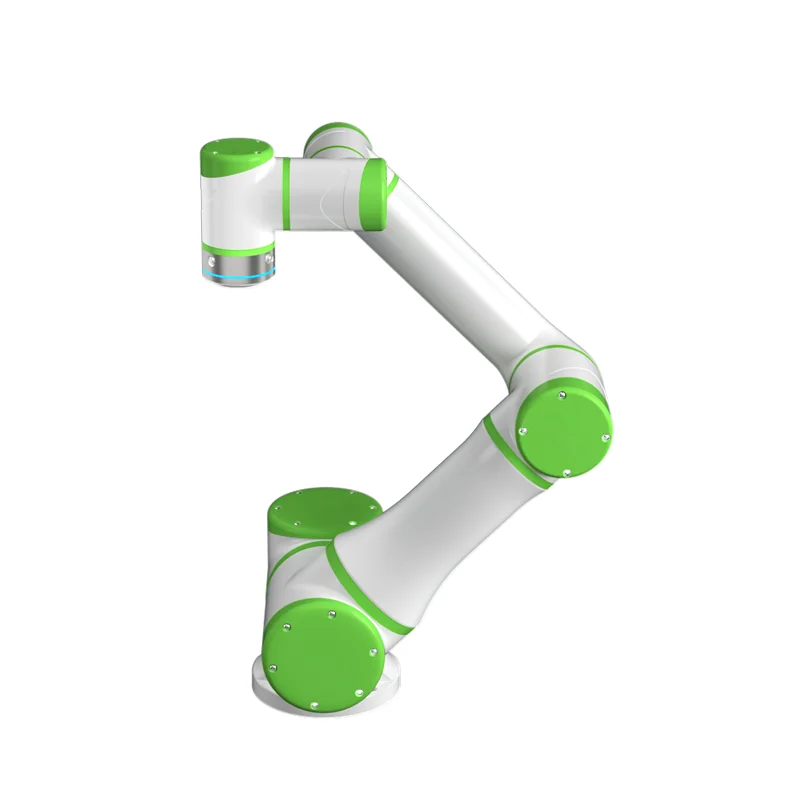

The introduction of six-axis robots signifies a substantial advancement in automation technology. These precision and adaptability-driven robots are capable of manipulating objects along six distinct axes, enabling them to execute maneuvers that closely resemble those of the human arm. Not only does this capability confer a mechanical advantage, but it also provides an advanced degree of control and adaptability across a multitude of applications. An exemplary manifestation of this technology is the R12-135S model, which features a noteworthy projectile capacity of 12KG and an armspan of 1300mm. The precise execution of intricate tasks is facilitated by its six degrees of freedom, as evidenced by its ±360° motion range in multiple joints and a repeat positioning accuracy of ±0.02mm.

Beyond their mechanical capabilities, six axis robots offer numerous advantages. They are leaders in the domain of collaborative robotics, which places significant emphasis on ensuring secure interactions between humans and robots within shared workstations. The product in question demonstrates exceptional performance in this field by providing a compact and lightweight design that enables operation in confined spaces without sacrificing functionality. The collaborative nature of this technology not only improves operational efficiency but also guarantees safety, rendering it an indispensable resource in contemporary logistics settings.

The Development of Intelligent Logistics

IoT, AI, and robotics are used to optimize supply chain operations, which is at the heart of the smart logistics concept. The objective is to develop interconnected systems that possess the ability to autonomously make decisions and adapt in real-time to dynamic conditions. A key component of this methodology is automation, specifically the use of six axis robots. By incorporating these robotic systems into their logistical processes, businesses can attain unparalleled levels of effectiveness, precision, and velocity.

The implementation of smart logistics requires the use of six-axis robotics, such as the R12-135S model. Their capacity to execute a diverse array of duties with exceptional accuracy and dependability caters to the fundamental requirements of the logistics industry—rapidity, adaptability, and effectiveness. The incorporation of these robotics into logistical processes signifies a substantial advancement in the automation of intricate duties, affording enterprises the ability to mitigate human fallibility, improve operational security, and decrease expenditures.

Six axis robots have capabilities that go far beyond simple manual labor in the context of smart logistics. They play a crucial role in the advancement of advanced, data-centric logistics systems capable of forecasting fluctuations in demand, adjusting to emerging operational obstacles, and perpetually optimizing procedures. The product in question, notable for its sophisticated technical specifications and collaborative functionalities, serves as a prime illustration of how six axis robots are not merely an element of the logistics ecosystem, but rather a critical factor in influencing its trajectory.

Implementations of Six-Axis Robots in Intelligent Logistics

Six-axis robots, including the R12-135S model, are revolutionizing the standards of efficiency and accuracy across a multitude of logistical processes. They are ideal for a vast array of duties due to their adaptability; they can handle and palletize products, execute pick-and-place operations, and even perform arc welding when required. In the logistics industry, where requirements can vary substantially from operation to operation, this adaptability is vital.

Palletizing and Handling

Six axis robots provide unrivaled speed and accuracy when handling and palletizing. With its 1300mm reach and 12kg payload, the R12-135S model can organize products onto palettes for transportation or storage with efficiency. Its precise motion control reduces the risk of injury to merchandise by ensuring that it is handled with care.

Assign and Select

Pick and place operations are significantly enhanced by the robot’s capacity to function in confined spaces. Collaborative functionalities and a compact form factor enable it to operate in tandem with human operators, thereby augmenting efficiency while upholding safety standards. The high repeatability of the robot guarantees consistent positioning, which is essential for fulfillment centers to maintain order accuracy.

Arc-Based Welding

Although untraditionally linked to logistics, the robot’s versatility is exemplified through its utilization in arc welding applications. The precision with which the R12-135S can carry out welding tasks in the fabrication of logistics equipment or vehicle modification exemplifies the wide-ranging utility of six axis robots in facilitating logistics operations beyond routine duties.

Collaborative Robots: Human Potential Expansion

Cobots, or collaborative robots, are an important development in robotics that are specifically engineered to operate securely in a shared workstation alongside human workers. Equipped with safety and efficiency-enhancing features, the R12-135S model personifies this collaborative ethos. The transformative capacity of cobots in the workplace is demonstrated by their capacity to free humans from harmful and repetitive duties.

Strengthening Safety

Due to the R12-135S’s collaborative nature, the likelihood of workplace accidents is reduced. Through assuming perilous responsibilities, such as operating in hazardous environments or performing heavy hauling, the automaton guarantees a more secure workplace for human personnel.

Increased Efficiency

Cobots such as the R12-135S serve the purpose of augmenting human labor rather than merely substituting it. By performing repetitive or physically taxing duties, cobots enable human employees to allocate their attention to more intricate or innovative facets of their occupations, consequently enhancing overall job satisfaction and productivity.

Uncomplicated Integration

Integration simplicity with regard to cobots into pre-existing workflows constitutes an additional noteworthy benefit. For instance, with its minimal space requirements and ability to be installed at any angle, the R12-135S is an ideal addition to any logistics operation seeking to automate without undergoing significant reorganization.

Difficulties and Solutions

Although six axis robots offer clear advantages, their integration into logistics operations is not devoid of obstacles. The aforementioned factors encompass the initial investment requirement, the necessity for proficient personnel to oversee and uphold the robotics systems, and the incorporation of said systems into pre-existing logistical processes.

Addressing Obstacles to Adoption

These obstacles are overcome by the R12-135S model’s economical construction, user-friendliness, and adaptable installation alternatives. The logistician’s technical specifications, including its energy-efficient 550W power consumption and IP65 rating, contribute to its sustainability and durability. Operating and maintaining the system is simplified through training, which is facilitated by the user-friendly interface and manufacturer support.

Preparing Logistics Operations for the Future

A step toward future-proofing logistics operations is to invest in six axis robots such as the R12-135S. With the continuous evolution of these technologies, their integration into logistics will progress towards greater seamlessness, resulting in enhanced efficiency and flexibility.

Intelligent Logistics in the Future: Six-Axis Robots

The development of six axis robot technology is fundamental to the future of smart logistics. The exponential advancements in artificial intelligence, machine learning, and robotics present an immense opportunity for these machines to augment logistics operations. With its collaborative features and sophisticated capabilities, the R12-135S model is only the beginning.

Exceeding Automation

Greater autonomy and decision-making capabilities represent the next frontier for six axis robots in logistics. Subsequent models have the potential to anticipate and adjust to real-time modifications in the logistics environment, thereby augmenting the efficiency of the supply chain.

Human-Robot Collaboration Is Strengthened

With the progression of cobot technology, it is foreseeable that interactions between humans and robotics will become more intuitive, accompanied by improved safety functionalities and more streamlined collaborative workflows. More than mere task automation, the objective is to establish a mutually beneficial association between humans and robotics, capitalizing on their respective strengths.

Conclusion

The R12-135S model is an example of a six-axis robot that is leading the way in the evolution of smart logistics. Their collaborative nature and capacity to execute a diverse array of duties with accuracy and effectiveness render them indispensable assets in the pursuit of more intelligent and streamlined logistics operations. Anticipating the forthcoming developments, the incorporation of these robotics into the logistics industry is poised to intensify, offering the potential for heightened operational efficacy and a reconceptualized function for human laborers within the sector. Adopting six axis robots signifies a dedication to a more streamlined, secure, and pioneering logistics industry, transcending mere technological investment.