Source: Unsplash

A sensor is a robot’s view of the outside world. Robots use sensors to comprehend and measure the geometric and physical features of objects in their surroundings. Robots, especially autonomous robots, require the ability to sense their surroundings.

Internal and exterior sensors are the two types of sensors that are commonly used. Internal sensors in robotics provide information on the robot, such as where it is, how fast it is going, and how it accelerates, among other things. External sensors in robotics collect data from the outside world including information such as the point of contact between a hydraulic robotic arm and the product it;s working on.

There are different types of sensors in robotics to pick from, and we’ll go over the properties of a number of them, as well as why and where they’re employed.

Light Sensors

Source: Unsplash

A light sensor in robotics is used to detect light and create a voltage differential. A computer-controlled camera in the robot vision system allows the robot to view and adapt its actions accordingly. Photoresistors and Photovoltaic cells are the two most used light sensors in robots. Phototubes, phototransistors, CCDs, and other light sensors are rarely employed.

A photoresistor is a sort of resistor whose resistance changes as the amount of light shines on it; more light means less resistance, and less light means more resistance. They are simple to integrate into light-dependent robotics.

Solar photovoltaic cells turn sunlight into electricity. This is particularly useful for developing a solar robot. While a photovoltaic cell can be considered an energy source, it can also be converted into a sensor with the use of transistors and capacitors.

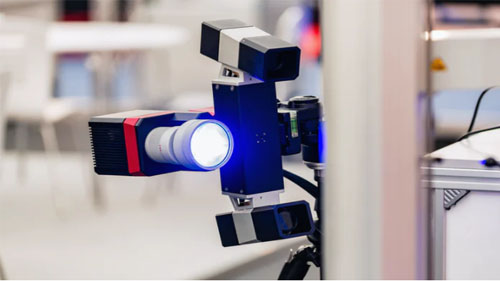

2D & 3D Vision: A two-dimensional computer vision image is flat, scaled to calculate length and width but not height. Even though the location and position of the elements vary, three-dimensional vision allows a robot to determine the orientation of a part that has to be handled more effectively. A robotic arm may be precisely guided by a 3D vision system during assembly, and a robotic arm can provide various viewing angles for important assembly inspection.

Sound Sensors

Source: Unsplash

Sound sensors in robotics work in a similar way as microphones, but they’re usually connected to circuits that assess the amplitude of the sounds to a threshold value and report the result to the robot. The noise becomes louder as the amplitude increases.

This could be useful for a robot that studies wildlife; detecting and following loud noises could be one of the data points used to locate wildlife. A sound sensor for voice recognition, which responds to commands spoken by a user, is a more complicated application.

A basic robot can be programmed to travel by listening to sounds. Consider a robot that makes one clap to the right and two claps to the left. Speech and voice recognition can both be done using the same microphone in complex robots. Sound sensors are more difficult to implement than light sensors as they produce a very small voltage difference that must be amplified to produce a discernible voltage change.

Proximity Sensors

Source: Unsplash

A proximity sensor in robotics can detect a nearby object without requiring physical touch. The transmitter sends electromagnetic radiation to the sensor next to it, and the receiver receives and analyzes the interruption feedback signal. As a result, the amount of light received in the area can be utilized to determine whether or not neighboring objects are present. For the robot, the sensors provide a collision avoidance approach.

There are many different types of proximity sensors, but only a few are commonly employed in robots.

Infrared (IR) transceiver: Once an obstacle is detected, an IR LED sends an IR beam of light that mirrors the light received by an IR recipient.

Ultrasound Sensor: These sensors produce high-frequency sound waves, and the recorded echo indicates that an object has been disrupted. Ultrasound sensors could be used to measure distances as well.

Photoresistor: Although a photoresistor is a light sensor, it can also be used as a proximity sensor. When an object approaches the sensor, the amount of light changes, causing the Photoresistor’s resistance to alter. This is something that can be detected and dealt with.

Tactile Sensors

Source: Unsplash

A tactile sensor is a device that determines whether or not an object is in contact. A tactile sensor enables the robot to “touch and feel” commonplace objects like stair rails and lighting that dim or brighten by pressing the base. These sensors are used to monitor applications and interact with the environment in a gentle manner. It is divided into two categories: Touch and Force Sensors.

Touch Sensors

Touch Sensors in robotics, also known as contact sensors, are devices that can detect and sense the touch of a sensor or an object. Micro-switches, limit switches, and other small devices are often utilized. The majority of these sensors are employed by robots to avoid obstacles. When these sensors detect an obstruction, the robot is given a task that can be reversed, turned, switched on, stopped, and so on.

Force Sensors

Force sensors in robotics are used to calculate the forces involved in a robot’s various functions, such as machine loading and unloading, material management, and so on. This sensor will also improve the assembling process for troubleshooting. A force torque sensor gives the robotic arms the feel of completing an assembly task; internal state sensors are used for measuring the end effector.

Temperature Sensors

Source: Pinterest

Temperature sensors in robotics measure heat/temperature changes in the environment where they are employed. It works on the concept of a voltage differential change for a temperature change; this voltage change provides the equivalent temperature of the surrounding area. Air temperature, surface temperature, and immersion temperature are all applications for temperature sensing.

Navigation and Positioning Sensors

Source: Pinterest

Positioning sensors in robotics are used to estimate the robot’s positioning. A GPS is the most common positioning sensor (Global Positioning System). Satellites orbiting our planet send out signals, which are picked up and processed by a robot receiver. Calculate a robot’s approximate position and velocity using the analyzed data. The three most common navigation sensors include;

GPS

The Global Positioning System (GPS) is the most widely used positioning sensor. Satellites orbiting our planet send out signals, which are picked up and processed by a robot’s receiver. The processed data can be utilized to calculate a robot’s approximate position and velocity.

These GPS systems are incredibly useful for robots in the outdoors, but they are ineffective indoors. They’re also a little pricey right now, but if their prices drop, you’ll soon see most robots equipped with a GPS module.

Digital Magnetic Compass

Similar to a portable magnetic compass, the Digital Magnetic Compass uses the earth’s magnetic field to produce directional measurements, guiding your robot in the appropriate direction to reach its target. These sensors are less expensive than GPS modules, however if you need both positional feedback and navigation, a compass should be used in conjunction with a GPS module.

Localization

The task of autonomously determining the location of a robot in a complex environment is known as localization. External elements called landmarks, which can be either purposefully placed or natural landmarks, are used to determine location. Artificial markers or beacons are put around the robot in the first phase, and the robot’s sensor records these signals to identify its exact location.

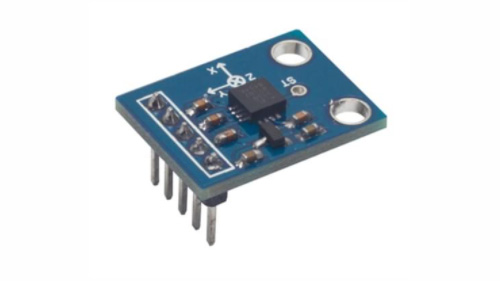

Acceleration Sensors

Source: Pinterest

Acceleration sensors in robotics are devices that measure the acceleration and tilt of the robot. An accelerometer is affected by two types of forces:

The Static Force – the force that exists between any two objects. We can determine how much the robot tilts by detecting its gravity. This parameter is useful for balancing robots or assessing if a robot is going uphill or downhill.

Dynamic Force – The speed with which an object must be moved. The speed/speed at which a robot travels is determined by measuring dynamic force with an accelerometer.

Other Robotic Sensors

Source: Unsplash

There are hundreds of sensors available now that can sense practically anything you can imagine, and it’s nearly hard to list them all. Aside from the ones listed above, there are a variety of other sensors that are utilized for specific applications. Consider the following conditions:

Humidity Sensors are used to determine the amount of moisture in the air. Moisture content

Gas sensors are made to detect specific gases.

Potentiometers are extremely versatile and can be utilized in a wide range of applications.

Magnetic Field Sensors measure the strength of the magnetic field that surrounds them

Conclusion

A couple of photoresistors or an infrared sensor can be used to make a simple obstacle avoidance robot. The more complicated your robot becomes, the more sensors it will have. A single operation may necessitate the use of multiple sensors, or several jobs may be accomplished with a single sensor.

A task can sometimes be completed using any of the several sensors available. Based on availability, affordability, and convenience of use, choose the ideal sensor. However, there is also the option of buying a robotic arm with a sensor attached to it by the manufacturer. This ideally saves you the cost of buying each independent of the other.