Joints are everything when it comes to robotic arm movements. Without joints, all you have is a straight metal pole that cannot move in any direction nor twist in any way. When it comes to robotic arms, the number of joints determines how efficient the entire structure would be.

We are going to look at the different types of joint designs, how they function, the benefits and limitations they may have, and how one can make the best out of them. If you have been thinking of automating your manufacturing process and are unsure of what to go for, understanding joint designs may give you an insight on what to go with.

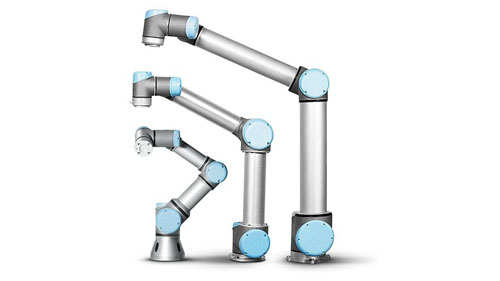

Robot Joints Explained

Source: Pinterest

Joints refer to any movable parts of the robotic arm, and since these machines are designed with the human arm in mind, it is normal to see them have a number of joints that accords them the freedom to move around as much as they are needed to.

For optimal functionality, each joint has to work independently but at the same time in seamless collaboration with the other. This is how a robotic arm is able to rotate while moving up and down at the same time. In a nutshell, a robotic arm cannot work without joints, and the minimum a proper industrial robotic arm can have is two joints. The higher the number of joints, the more reliable the robotic arm is.

In most cases, these joints are referred to as axes and are essential in determining how a robotic arm will work. Understanding the mechanism behind the joints is the best way you can learn more about the operations of every component that makes up the robot.

Types of Joints

Source: Pinterest

There are about 5 types of joints that you will find in any given type of robotic arm. Each joint is designed for a specific function and switching them up for another role without proper calibration can lead to damage.

Linear Joints: These are also called parallel joints whose movement is determined by lateral motions every time the arm gets into some action. This leads to a special movement called the translational movement that can be seen best in the way pistons move. Linear joints are quite powerful and can be used in robotic arms that handle heavy work like pick and place robots, among others.

Twisting Joints: This is a joint that makes use of rotary motions to cause motions. The movement is relative to the rotation axis, which is directly perpendicular to the input and output link axes. They are also called t-joints, and they are commonly used for drilling robots that have to twist and turn at high speeds to punch holes into hard surfaces.

Orthogonal Joints: These are robotic arm joints whose movement is banked on the output and input links. In layman terms, this is a sliding type of movement that’s translational and works with a linear arrangement of joints. In this setup, the output link is directly perpendicular to the input link, and this is the reason behind the translational sliding motion that is triggered once the robotic arm comes to life.

Revolving Joints: These feature a rotational movement between two links that have the input link axis parallel to the rotation axis, like the rest that tend to have a perpendicular setup. Also called the V-joint, the revolving joint is easy to confuse with a twisting joint, but their applications are wildly different in the manufacturing space.

Rotational Joints: These are joints that are best suited for robotic manipulators as they are extra precise in their movements. The motions are triggered by the rotation of the axes that’s perpendicular to the input and output links axes. Popularly known as type r joints, the rotational joint is the type you will find in fast robotic setups that prioritize accuracy and speed.

Benefits and Limitations of Joints in Robotic Arms

Source: Pinterest

Good as they may be at what they do, robotic arms are not without fault. Being mechanical, it is normal to have a few mechanical malfunctions once a certain threshold of usage is attained. The following are the benefits and limitations of robotic joints.

Benefits

They allow for freedom of movement, and this is what makes industrial robots very versatile. A simple change in programming can repurpose a welding robot into a painting one without any need to buy a new one.

Joints give robots structure which in turn makes it easy to repair and maintain them. Once a fault occurs, it is easy to track it to a joint rather than making wild guesses.

Joints are flexible, and this gives the robotic arms the ability to twist and turn, to rotate, to go up and down. Without these movements, a robotic arm is nothing more than an expensive piece of junk.

Limitations

Joints are points of weakness due to constant movements. The wear and tear that occurs are where most of the damage sustained by industrial robots begins. It is unavoidable; the best that can be done is to delay it.

It is costly to repair or replace a joint, especially if you are not in close proximity to the original manufacturer. Finding a compatible replacement is hard, and this could derail the space of production since nothing can take place even when a single piece is missing.

Conclusion

Robotic joints are an important part of automation. As time goes by, it is becoming easier for manufacturers to switch to automation as robots with better joints are being designed. If you are looking to also go down that route but are lost on where to begin, check out our website, and you will find all the information you need to make the right choice.