Introduction

The modern industrial environment is changing quickly, and manufacturing processes are depending more and more on robotic automation. With each providing special features that improve accuracy and productivity, SCARA robots and welding robots have grown to be significant parts of the industrial robot industry. Because it may change the efficiency and flexibility of industrial processes, the integration of SCARA technology with welding robots is a significant advance. This thorough guide looks at the characteristics, uses, and integration of these two kinds of robots, emphasizing their revolutionary effect on production.

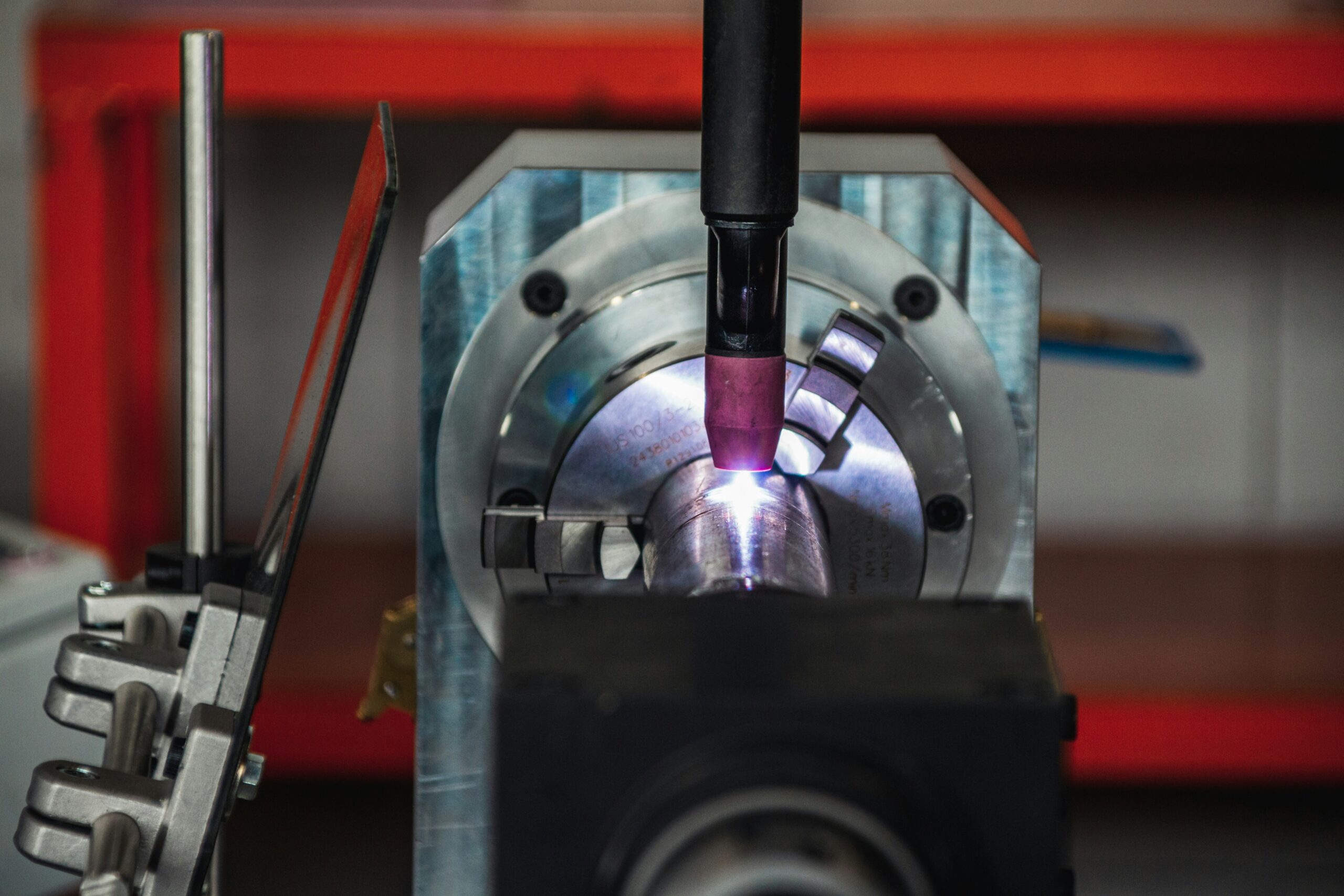

Robot Comprehension Through Welding

Robotic systems with specialized functions, welding robots are designed to perform welding operations with remarkable accuracy and reliability. Because of their powerful sensors and control systems, these robots can undertake intricate welding processes with minimal human assistance. Welding robots provide the following key benefits:

Increased Accuracy and Precision: Welding robots provide consistent welds, improving product quality and lowering the likelihood of mistakes.

Efficiency Gains: These robots’ rapid speeds enable them to produce goods at significantly higher rates.

Wide range of applications: Welding robots can work with a number of materials, including carbon steel, copper, aluminum, and stainless steel.

One notable example is the 6KG payload 2014mm reaching distance 6 axis welding robot, QJR6-2000H. This robot is a prime example of the cutting-edge capabilities and technology that make welding robots essential in modern production.

Comprehensive Investigation of the QJR6-2000H Welding Robot

Because of its advanced capabilities and durable construction, the QJR6-2000H welding robot is notable. These are the primary characteristics:

Precision welds are guaranteed by the Gear Gaps Adjustment Structure, which enhances joint accuracy.

Enhanced joint support stiffness is achieved through the use of a hollow structure with a U-shaped wrist design, which in turn provides increased flexibility.

Noise Reduction Structure: Patented noise reduction structure reduces operating noise, rendering the robot suitable for a variety of industrial settings.

Antishake Optimization: This feature enhances system stiffness and minimizes control errors by decreasing end clearance.

QJR6-2000H guarantees consistent, high-quality welds with a repeat positioning accuracy of ±0.08mm.

Armspan Expansion: The robot’s armspan of 2014mm enables it to access a broad range of areas, rendering it adaptable to a variety of applications.

Specifications of Technique

QJR6-2000H.

6 Axis Number

6 kg of payload

Replicate Positioning: ±0.08mm

2014mm maximum arm span

Motion range: J1 ±175º, J2 +159º, -95º, J3 +95º, -125º, J4 ±183º, J5 +129º, -126º, J6 ±360º

Maximum Speed: J1 189º/s, J2 189º/s, J3 189º/s, J4 378º/s, J5 320º/s, J6 687º/s

Max. Torque: 8.81N.m for J4, 8.81N.m for J5, and 3.14N.m for J6

J4: 0.2g.m², J5: 0.2kg.m², and J6: 0.03kg.m²: Inertia Moment;

Weight of the robot body: 230 kilograms

Power Consumption: 3.4 A

Dimensions of the cabinet are 580650960mm, and it weighs 130kg.

Energy source: 380V ±10%, three-phase, four-wire

Installing Form: Ceiling, Ground

Utilization: for welding

The versatile QJR6-2000H is engineered to accommodate a diverse array of materials, rendering it an ideal solution for a variety of industrial applications.

Examination of SCARA Robots

Selective Compliance Assembly Robot Arm robots, or SCARA robots for short, stand out for their extraordinary speed and accuracy. Some jobs that need quick, repetitive motions are ones that these robots excel at, such handling, assembling, and packaging. The advantages of SCARA robots are as follows:

Compactness and Flexibility: SCARA robots are engineered to function in restricted areas as a result of their compact design.

Rapidity of Movement: These robots are capable of completing tasks at a rapid pace, thereby increasing overall productivity.

SCARA robots provide precise movements with minimal noise, thereby improving the working environment, thanks to their high transmission accuracy and low noise content.

3 kg of payload One of the most prominent illustrations of SCARA robots‘ capabilities is the 400mm 4 Axis Universal SCARA robot EVS3-400. This robot is optimized for light-duty applications and executes exceptional tasks in the areas of palletizing, handling, assembly, and working with 3C products.

Description of the EVS3-400 SCARA Robot in Greater Detail

Due to its compact and efficient design, the EVS3-400 SCARA robot is revered. These are the primary characteristics:

Optimal for intricate assembly lines, the EVS3-400’s compact and adaptable design enables it to occupy constrained spaces.

Rapid Speed: This robot has the capacity to operate at high speeds, which can vastly increase production rates.

Superb Transmission Precision: The robot’s precision guarantees exceptional outcomes in each operation.

In environments where noise reduction is essential, the EVS3-400 is an ideal choice due to its quiet operation.

Specifications of Technique

Specification: EVS3-400

Function: Manages 3C products and material handling.

Four axes in total.

A maximum reach of 400mm is achievable.

Payload: Maximum load 3, rated load 1 kg

Allowable Rotating Axis Inertial Torque: Maximum torque: 0.05 kg·m², torque rating: 0.005 kg·m²

The accuracy of repeated positioning is as follows: ±0.01mm for the first and second axes, ±0.01mm for the elevating axis, and ±0.01° for the rotation axis, which is the fourth axis.

Four rotational axes are available: the first can rotate at 720°/sec, the second can rotate at 720°/sec, the third may elevate at 1000 mm/sec, and the fourth can rotate at 1500°/sec. The stated maximum speed applies.

Maximum working area: ±132° for the first axis, ±141° for the second, 170° for the third (elevating axis), and ±360° for the fourth (rotation axis).

Installation Method: Floor-mounted Robot Weight: 13 kilograms

Usage of electricity: 0.7 kilowatts

Ecology of Installation: Temperature range: 0 to +45℃, humidity range: 20 to 80%RH (no condensation), and vibration of less than 4.9M/S². Application: Capable of collaborating with a vision system. For the purpose of material loading, unloading, sorting, and handling.

Because of its efficiency and adaptability, the EVS3-400 is an invaluable asset to any production line.

Integrating SCARA Technology with Welding Robots

SCARA robots and welding robots are integrated to provide a variety of advantages, including increased efficiency and adaptability in manufacturing processes. Principal advantages consist of

Improved Precision and Efficiency: The integration of SCARA robots‘ speed and the precision of welding robots leads to improved quality and faster production times.

Flexible and adaptable: The integration enables the seamless execution of more intricate tasks, thereby enhancing adaptability in a variety of industrial applications.

Operational Efficiency: By automating intricate sequences, integrated systems can decrease production time, thereby reducing operational complexity.

Examinations of Particular Situations

Line of Automotive Assembly: An automotive manufacturer implemented the automation of the welding and assembly processes by integrating SCARA robots with welding robots. The integration of the combined system resulted in a 35% increase in production speed and a 20% reduction in defects, which emphasized its efficiency and precision.

Integrated systems of SCARA robots and welding robots were employed by an electronics company to assemble intricate components. The integrated robots’ flexibility and precision led to a 25% augmentation in production efficiency and a substantial decrease in assembly errors.

Application of Technical Knowledge to Integration

Successfully integrating SCARA robots with welding robots necessitates meticulous consideration of numerous variables:

Integrity and Synchronization: It is imperative to guarantee that the robots’ software and control systems are compatible in order to achieve a seamless integration.

Maintenance and Installation: The integrated system must be correctly installed and maintained on a regular basis to ensure its optimal performance.

Integrated systems are illustrated by the following; The successful integration of these robots into a variety of industries has led to enhanced production processes and product quality.

The Future of Robotic Integration

There is considerable potential for the future of robotic integration, as a number of emerging technologies are expected to improve the capabilities of SCARA robots and welding robots:

Robotics will be able to adjust to a wide range of jobs and improve operations in real time thanks to advanced AI and machine learning.

Collaborative robots, or cobots, combine human flexibility and robotic accuracy to operate alongside human operators.

Advanced materials and designs may enable a broader selection of customization options, accuracy, and stability to be attainable in the future for robot integration.

Issues such as the necessity of specialized skills to operate and maintain these systems and the high initial costs persist, despite the promising advancements. Nevertheless, to address these obstacles, it is possible to implement ongoing innovation and training programs.

Conclusive

An important development in industrial automation is the integration of SCARA technology and welding robots. In contemporary manufacturing, these robots are indispensable assets due to their combined capabilities, which improve precision, efficiency, and flexibility. A new era in manufacturing and automation is on the horizon as these advanced systems continue to be adopted and integrated by industries, resulting in substantial improvements in productivity and quality.