Introduction

Efficiency is critical in modern manufacturing. EVS has revolutionized workflow efficiency, increased productivity and reliability with the Platform Two Axis Servo Positioner and Single Axis Welding Positioner. EVS’s advanced systems integrate welding positioners, AC servo motors and welding robots to provide superior performance. Let’s take a look at how EVS’s servo positioners can transform your manufacturing processes and ensure unparalleled precision and efficiency.

Enhancing Precision with Welding Positioners

Welding positioners are essential in optimizing the performance of EVS’s servo positioners. These welding positioners ensure precise control and optimal positioning during welding tasks. By integrating high-quality welding positioners, EVS guarantees superior performance.

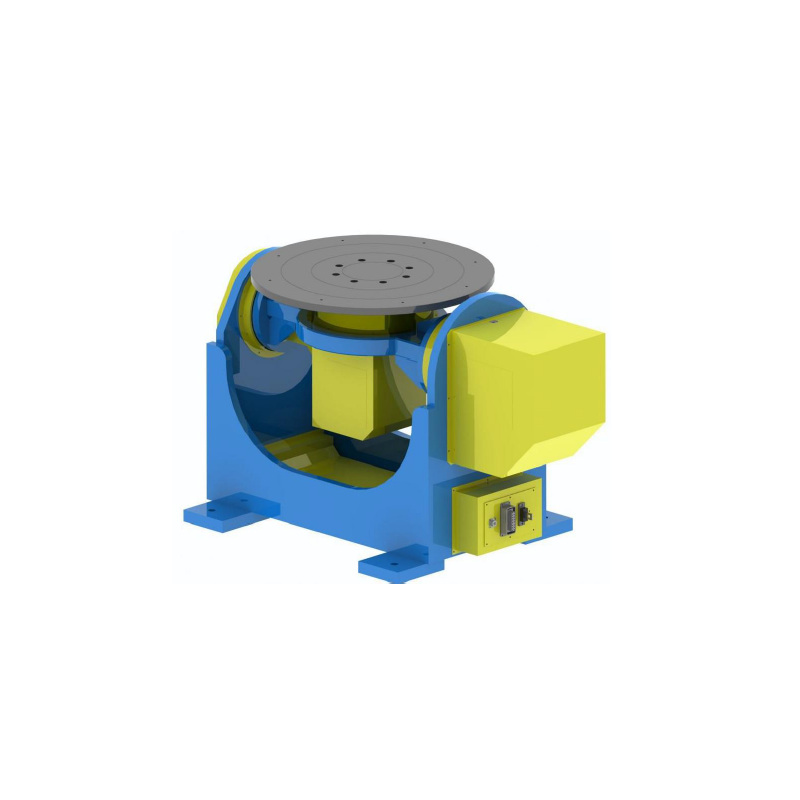

The efficiency of EVS servo positioners is the core of welding robots. Servo positioners, rotary spindle boxes and tail boxes, welding rotary frames, AC servo motors, RV precision reducers, conductive systems and high-quality welding positioners allow welding robots to perform welding tasks with high precision. High-quality profile processing ensures processing accuracy and use accuracy. High-quality welding robots ensure long-lasting performance and reduce maintenance. Welding robots are essential to achieve the required precision and efficiency in various applications.

AC servo motors are another critical component in these positioners. These motors work seamlessly with welding positioners to deliver precise motion control. AC servo motors provide high torque at low speeds, essential for accuracy. The premise for smooth and precise motion is the combination of AC servo motor and welding positioner.Their integration ensures consistent performance and minimal downtime.

Increasing Workflow Efficiency

Workflow efficiency is critical in manufacturing. EVS’s servo positioners, equipped with welding positioners, significantly enhance workflow efficiency. These welding positioners provide the necessary control and accuracy for efficient welding operations. The integration of welding positioners ensures smooth and efficient operation. This efficiency translates to higher productivity and reduced downtime.

AC servo motors contribute to increasing workflow efficiency. These motors provide precise control, ensuring accurate welding operations. The combination of AC servo motors and welding positioners enhances the overall system performance. High-quality AC servo motors ensure consistent and reliable operation. This reliability is crucial for maintaining workflow efficiency.

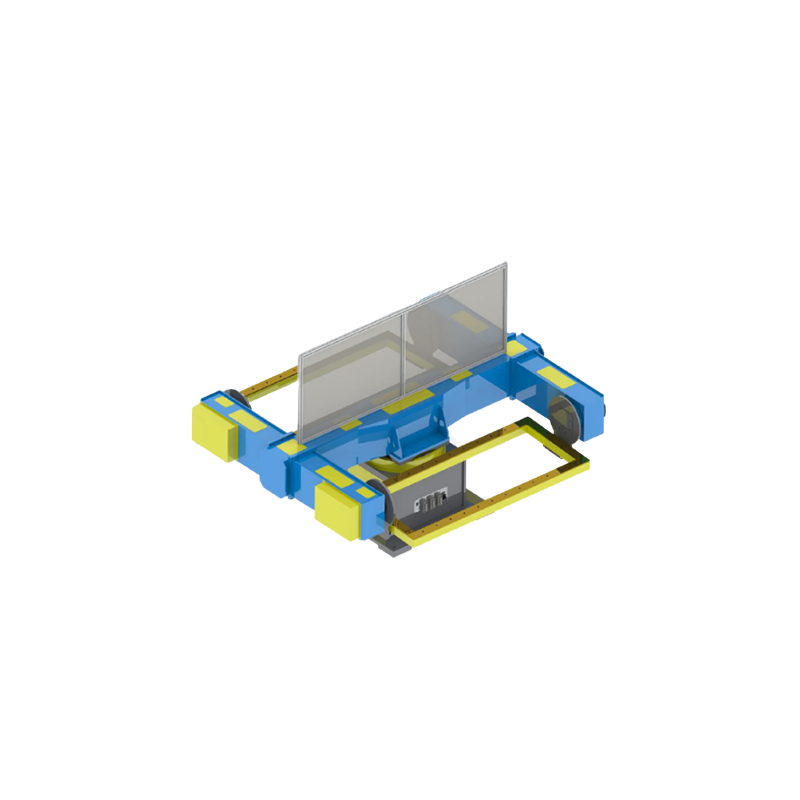

Welding robots also play an important role in improving the efficiency of the workflow. The single-axis welding positioner EVS-SWP-ZW-500/800/1200 single-axis servo positioner consists of a fixed base, a rotary spindle box and tail box, a welding rotary frame, an AC servo motor, an RV precision reducer, a conductive system, a protective cover, etc. These are the primary conditions for the robot to perform welding tasks with high precision and high speed. High-quality welding robots reduce the need for frequent maintenance. The reduction in maintenance work improves workflow efficiency to a certain extent.

High quality welding positioners reduce maintenance costs

EVS’s servo positioners with welding positioners effectively solve this problem. Durability and long-lasting performance are key to the design of welding positioners. High-quality welding positioners reduce the frequency of manual maintenance interventions. Reduced maintenance costs mean significant cost savings over time. AC servo motors also help reduce labor maintenance costs. By integrating high-quality AC servo motors and equipping welding positioners, EVS has ensured its performance. The combination of AC servo motors and welding positioners reduces wear on components. Reduced wear extends the life of the system.

Maintain security and compliance

Servo positioners and welding positioners must be designed to meet strict safety standards。 High-quality welding positioners minimize the risk of mechanical failures. This reliability is crucial for maintaining a safe working environment.AC servo motors also contribute to sustainability. These motors provide high efficiency, reducing energy consumption. By integrating AC servo motors with welding positioners, EVS ensures optimal performance. High-quality AC servo motors minimize the environmental impact of manufacturing operations. This efficiency supports sustainability initiatives.

Welding robots are designed for energy efficiency. These robots, equipped with welding positioners, ensure efficient operation. High-quality welding robots reduce energy consumption, supporting sustainability goals. This integration enhances overall system sustainability.

Increasing Flexibility and Adaptability

Flexibility and adaptability are crucial in modern manufacturing. EVS’s servo positioners, equipped with welding positioners, offer these qualities. These welding positioners can be easily adjusted to meet changing production needs. The integration of welding positioners ensures the system handles various tasks efficiently. This flexibility is essential for responding to market demands.

AC servo motors contribute to the system’s flexibility. These motors provide adjustable speed and torque settings. By integrating AC servo motors with welding positioners, EVS ensures adaptable performance. High-quality AC servo motors handle different operational requirements. This adaptability enhances overall system flexibility.

Welding robots also enhance system flexibility. These robots, equipped with welding positioners, provide adaptable performance. High-quality welding robots can be easily reconfigured to meet different production needs. This flexibility enhances overall system productivity.

Conclusion

The cutting-edge servo positioners and welding positioners from EVS are extremely important for producing high-quality welding robots. Integrating advanced welding locators and welding robots has improved the efficiency, accuracy, flexibility, and safety of the manufacturing industry. Servo locators greatly support sustainable development goals by reducing manual maintenance costs, making them an ideal choice for contemporary manufacturing environments. Investing in EVS’s servo locators can change your workflow, making it more efficient and reliable. For more information on how EVS can help improve your workflow efficiency, please visit EVS.