Introduction

Modern manufacturing is constantly evolving, with automation playing a critical role. EVS International’s 6kg and 12kg collaborative robots represent the pinnacle of cutting-edge technology. These six axis robots are designed to enhance efficiency and precision in various applications.This article will let you know how palletizing robots can change your manufacturing process and improve the accuracy and efficiency of production. It will also let you know clearly that collaborative robots are an indispensable part of automated production in modern manufacturing. Their flexibility and performance are the primary conditions for automated production.For more details, visit EVS International.

Six-axis robot improves production accuracy

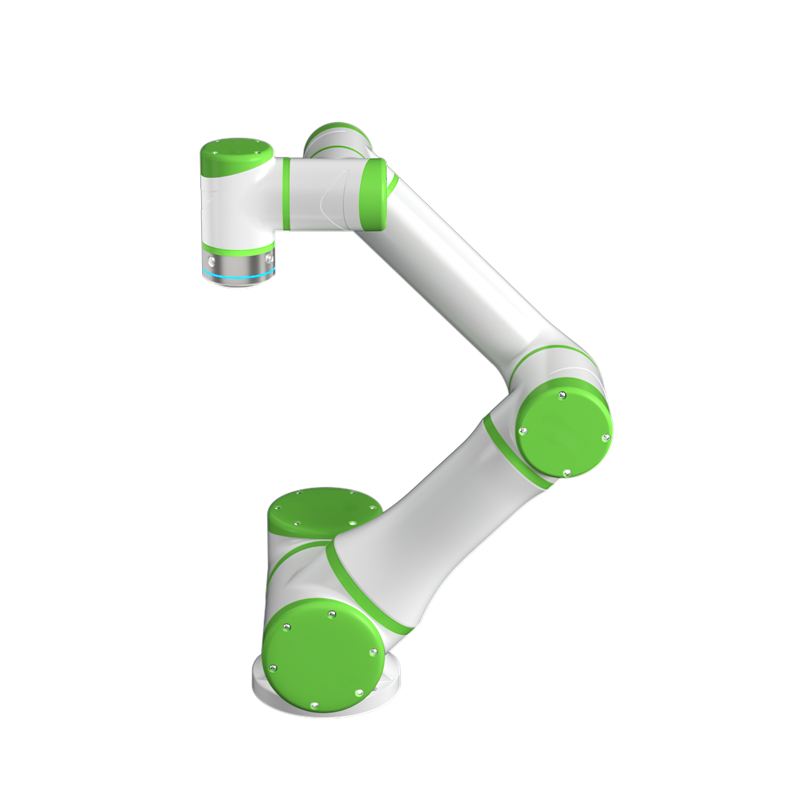

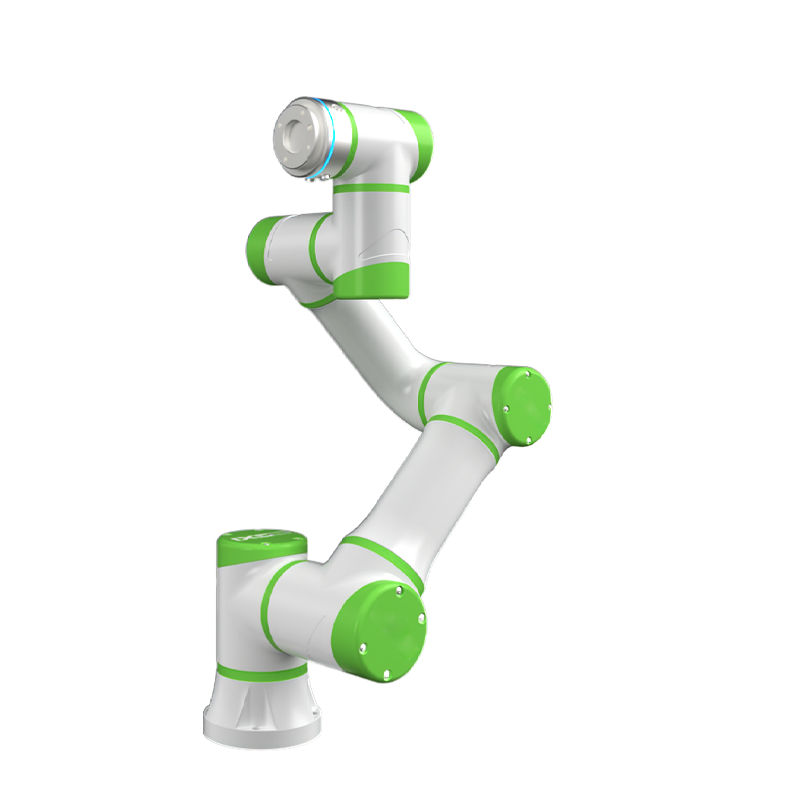

Six axis robots are essential for achieving high precision in automated tasks. EVS International’s 6kg collaborative robot excels in applications requiring meticulous accuracy. These six axis robots can perform complex movements with ease, ensuring flawless task execution. The six axis robots are equipped with advanced sensors and controls, adapting to various operational needs. For tasks such as welding, assembly, and inspection, these six axis robots offer unparalleled precision. The collaborative robot design ensures they work safely alongside human operators, enhancing workflow efficiency.

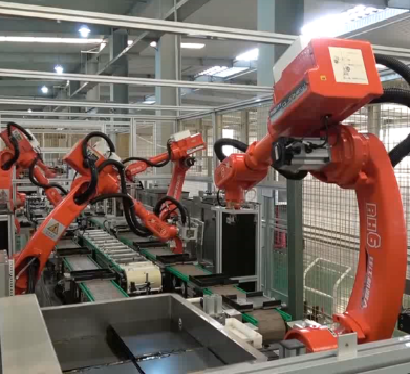

Palletizing robots, such as EVS International’s 12kg collaborative robot, are designed with advanced safety features to protect operators and efficiently handle payloads, which is essential for tasks involving lifting and precise placement of heavy objects. Palletizing robots simplify processes such as packaging and material handling, ensuring that products are stacked and organized with the highest precision.Sensors and control systems are strong configurations that palletizing robots must have. They can detect and avoid obstacles to a certain extent, preventing some injuries and accidents. Human-robot safe interaction has always been a research topic. Believe me, EVS International’s 12KG and 6KG six axis robots are definitely the best partners for humans and robots to work together.

Collaborative robots meet the flexibility required for many production activities. EVS International’s six-axis robot arms are mainly used for handling, palletizing, picking and placing, and arc welding. At the same time, the six-axis robots can be programmed to perform different tasks. At the same time, collaborative robots can operate multiple processes in a narrow space, are lightweight and compact. All of these designs can ensure seamless integration into your manufacturing process. With collaborative functions, collaborative robots can extend your time and space, freeing humans from repetitive work and dangerous environments while allowing your operations to remain efficient and competitive in a rapidly evolving market.

Enhancing Safety with Six axis robots

Safety must be the most important topic in the field of robotics, and the safety of collaborative robots in manufacturing environments is the most important concern. EVS International’s six-axis robot must be designed with the most advanced safety design because it involves protecting the safety of operators. Our 6kg payload 917 mm reach distance 6-axis collaborative robot is equipped with the most powerful sensors and control systems to ensure 100% safe human-robot interaction. At the same time, there is a very powerful autonomous setting, its range of motion from joint 1 to joint 6 reaches ±360°, our robot net does not include cables to reach 21 kg, the degree of freedom reaches 6, and we also have an intuitive programming interface that can be easily adjusted.

Improve workflow efficiency with palletizing robots

In this fast-paced manufacturing industry, work efficiency is a major competitive factor. EVS International’s palletizing robots improve efficiency by automating repetitive and labor-intensive tasks. EVS International’s 12 kg collaborative robot optimizes palletizing operations and can handle products precisely. The benefit of using a six-axis robot is that it can work tirelessly, which greatly improves production efficiency. Palletizing robots reduce the need for manual labor to a certain extent. Now that labor costs are increasing, palletizing robots will definitely save costs effectively, so that we can allow workers to focus more on complex tasks, and let palletizing robots help you complete simple and physical work.

Six-axis robots are essential for tasks that require complex movements and high precision. EVS International’s 6 kg collaborative robot is equipped with an advanced motion control system for smooth and accurate operation. Six-axis robots can integrate these advanced motion control systems into various production stages from assembly to inspection. The flexibility of collaborative robots is greatly increased, allowing them to adapt to different tasks to ensure flexible and efficient production lines. Using six-axis robots to automate key processes can improve workflow efficiency and overall productivity.

How to effectively use collaborative robots to reduce maintenance costs and create profitability

Collaborative robots, such as EVS International’s 6-axis collaborative robot, are designed with durability and minimal maintenance in mind. The 6kg payload 917 mm reaching distance 6 axis collaborative robot is manufactured with high-quality components for long-term reliability. EVS International’s 6-axis robots require less frequent maintenance, reducing downtime and costs. Investing in collaborative robots can significantly save maintenance costs and ensure continued efficient operations.

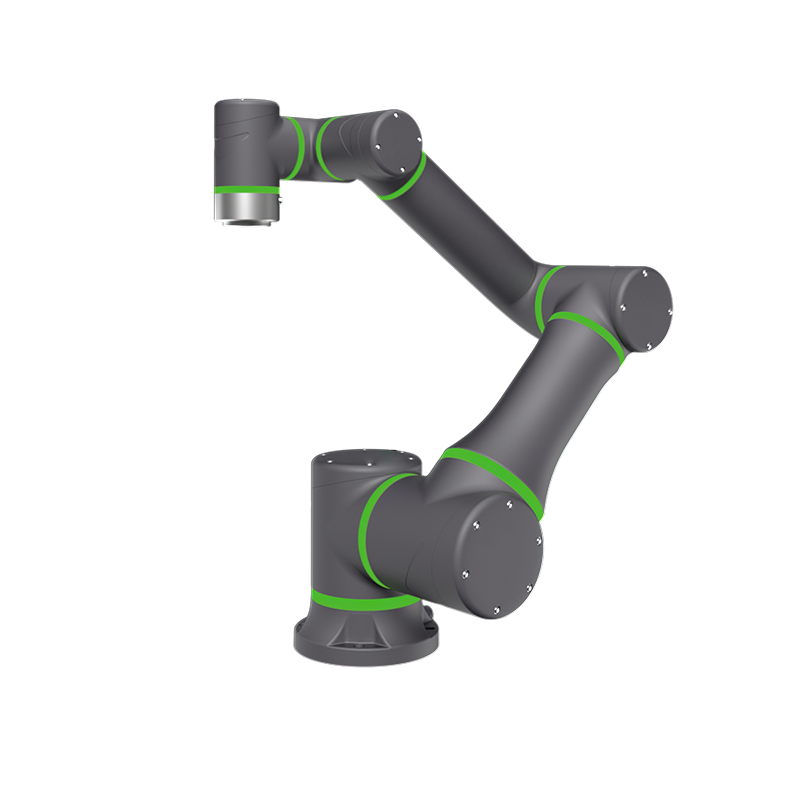

Palletizing robots, such as the 12kg payload 1300 mm reaching distance 6-axis collaborative robot, can handle heavy objects and are able to operate multiple processes in confined spaces. 6-axis robots are carefully designed to withstand ultra-intensive use, minimizing failures and maintenance costs. The rugged design of EVS International collaborative robots allows the robots to maintain consistent performance under heavy load conditions.

Enhancing Safety with Six axis robots

Safety is paramount in manufacturing. Collaborative robots, like EVS International’s six axis robots, have advanced safety features. The 6kg collaborative robot has sensors and control systems for safe human interaction. These six axis robots detect and avoid obstacles, preventing accidents. The collaborative robot’s safe human-robot collaboration makes it ideal for close interaction applications.

Palletizing robots, such as the 12kg collaborative robot, handle heavy loads safely. These six axis robots have advanced load monitoring systems to prevent overloading. The collaborative robot’s robust design ensures safe heavy lifting tasks. Integrating palletizing robots enhances workplace safety, reducing injury risks. The six axis robot’s safe interaction with humans and machines ensures a secure manufacturing environment.

Collaborative robots comply with stringent safety standards. EVS International’s six axis robots meet international safety certifications. The 6kg collaborative robot prevents accidental human contact. These six axis robots operate in confined spaces, reducing collision risks. The collaborative robot’s safety features ensure wide application use. Incorporating six axis robots into manufacturing creates a safer, more productive environment.

Improving Sustainability with Collaborative Robots

Sustainability is crucial in manufacturing. Collaborative robots, such as EVS International’s six axis robots, enhance sustainability by reducing energy consumption and waste. The 6kg collaborative robot has energy-efficient motors and controls. These six axis robots perform tasks precisely, reducing rework and waste. The collaborative robot’s efficient design minimizes environmental impact, ideal for sustainable manufacturing.

Palletizing robots, like the 12kg collaborative robot, optimize material handling processes. These six axis robots stack and organize products efficiently, reducing manual labor and energy use. The collaborative robot’s precise handling minimizes product damage and waste. Integrating palletizing robots achieves sustainability improvements and environmental impact reduction.

Collaborative robots are versatile and adaptable, optimizing production processes for sustainability. EVS International’s six axis robots can perform various tasks, from assembly to inspection. The 6kg collaborative robot’s flexibility allows quick production line reconfiguration, reducing downtime and waste. The six axis robot’s adaptability ensures high productivity with minimal environmental impact. Investing in collaborative robots achieves sustainable and efficient manufacturing.

EVS Internationalsix-axis robot has high flexibility and adaptability

Collaborative robots, like EVS International’s six axis robots, offer these qualities. The 6kg collaborative robot is easily reprogrammed for different tasks, ensuring seamless production integration. These six axis robots quickly reconfigure for new product lines. The collaborative robot’s adaptability ensures manufacturers can respond to market demands efficiently.

Palletizing robots, such as the 12kg collaborative robot, provide efficient material handling flexibility. These six axis robots handle different products and packaging configurations. The collaborative robot’s versatility adapts to varying production requirements, from stacking boxes to organizing pallets. Integrating palletizing robots enhances production flexibility, meeting diverse customer needs. The six axis robot’s flexibility ensures agile and responsive manufacturing processes.EVS International’s six axis robots integrate with conveyors, vision systems, and other equipment, creating a fully automated production line. The 6kg collaborative robot’s tandem operation with other machines ensures smooth and efficient processes. These six axis robots adapt to different workflows and layouts, optimizing manufacturing processes. Leveraging collaborative robots achieves an adaptable and efficient production line.

Conclusion

EVS International’s cutting-edge collaborative robots revolutionize modern manufacturing. Integrating advanced six axis robots and palletizing robots enhances efficiency, precision, flexibility, and safety. These servo positioners reduce maintenance costs and support sustainability goals, ideal for contemporary manufacturing. Investing in EVS International’s collaborative robots transforms workflows, ensuring efficient and reliable operations. For more information on improving workflow efficiency, visit EVS International.