An Overview of Robot tracks and Manufacturing Robotics

Integrating robot tracks and robotics in manufacturing has become essential in today’s manufacturing environment to increase operational effectiveness. Robots can now operate over greater distances thanks to robot tracks, which increase their operating range. This feature is critical for robotics in manufacturing, where productivity, accuracy, and adaptability are critical. One excellent example of the cutting-edge technology that businesses may utilize to increase productivity, streamline procedures, and save manual labor is the EVS Robot Walking Rail. These technologies are making production processes more adaptable and sensitive to market demands.

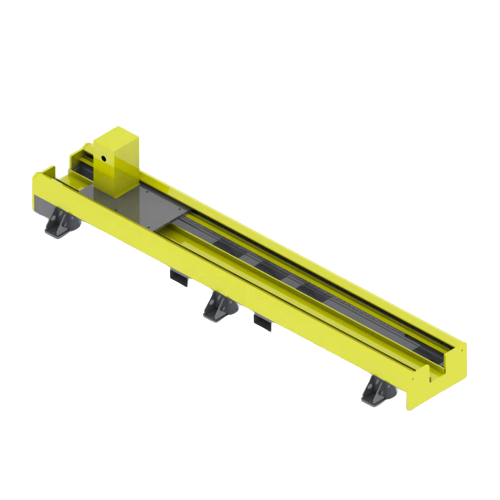

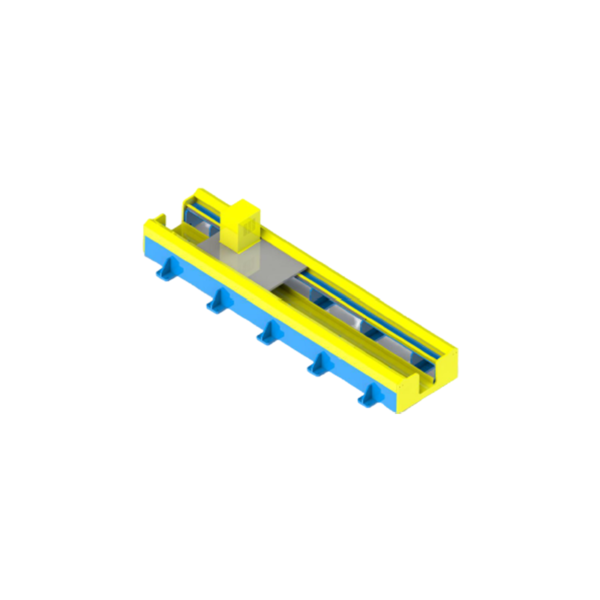

Features and Specifications of EVS Robot Walking Rail

The EVS Robot Walking Rail is designed to enhance the mobility and operational range of robotic systems. Key features include:

Model: EVS Robot Walking Rail

Rated Load Capacity: Up to 6000 kg, guaranteeing strong operation even while carrying large loads.

Repeat Positioning Accuracy: ±0.01mm, offering outstanding accuracy for jobs requiring high precision.

Maximum Speed: 1.5 m/s, which enables quick repositioning to keep throughput high.

Options for Rail Length: Adaptable to application requirements, providing versatility for various production configurations.

Material: Longevity and dependability in harsh settings are guaranteed by the high-strength steel.

Control System: Combined with cutting-edge servo motors for accurate control and seamless performance.

Compatibility: Improves overall functionality and adaptability by integrating seamlessly with a variety of robotic systems.

These specifications highlight how the EVS Robot Walking Rail can significantly improve the effectiveness of robotics in manufacturing. By offering customizable rail lengths and high load capacity, it supports a wide range of applications, from small-scale operations to large industrial facilities.

Benefits of EVS Robot Walking Rail

The finest of robotics in manufacturing and robot tracks come together in the EVS Robot Walking Rail. With the help of this cutting-edge device, robots may now move more freely and cover larger regions without the need for human readjustment. Manufacturers may streamline processes and guarantee that robots can easily access various workstations by integrating robot tracks. This is critical for robotics in manufacturing, where competitiveness is maintained through high throughput and continuous operation. With its sophisticated control systems, the EVS Robot Walking Rail guarantees accurate and reliable operation, lowering mistakes and increasing total efficiency. This combination produces notable gains in both production speed and quality, which makes it a vital tool for contemporary producers.

Enhancing Efficiency with Robot tracks

Implementing robot tracks significantly boosts the efficiency of robotics in manufacturing. Robot tracks enable continuous movement, minimizing idle times and ensuring that robots can swiftly transition between tasks. This capability is vital in robotics in manufacturing, where time and precision are critical. By facilitating seamless transitions, robot tracks help maintain high productivity levels. The integration of robot tracks into production lines leads to more streamlined operations, allowing manufacturers to achieve higher throughput without sacrificing quality. The precision offered by robot tracks also minimizes the risk of errors, ensuring reliable performance across the board. This efficiency translates into faster production cycles and reduced operational costs, making it a strategic investment for any manufacturing operation.

Flexibility and Scalability of Robot tracks

The flexibility and scalability provided by robot tracks are transformative in robotics in manufacturing. Robot tracks allow for easy reconfiguration of production lines to accommodate new tasks and products. This adaptability is essential in robotics in manufacturing, where quick response to changing demands is necessary. As production needs grow, robot tracks can be extended, supporting increased operational capacity without major overhauls. This scalability ensures that manufacturers can expand their operations smoothly. The versatility of robot tracks in robotics in manufacturing guarantees that production lines remain agile and capable of handling various tasks efficiently. This flexibility not only enhances current operations but also future-proofs the manufacturing setup against evolving industry requirements.

Improving Safety and Reducing Costs

Integrating robot tracks in robotics in manufacturing significantly enhances workplace safety. Robot tracks enable robots to handle hazardous tasks, minimizing human exposure to risks. This is a major advantage in robotics in manufacturing, where safety is a top priority. Additionally, robot tracks contribute to cost savings by reducing the need for manual labor. With robot tracks, manufacturers can allocate human resources to more strategic roles, enhancing overall efficiency. The efficiency brought by robot tracks in robotics in manufacturing leads to reduced operational costs and higher profitability. Long-term benefits of robot tracks include lower maintenance expenses and a better return on investment. This dual advantage of safety and cost-effectiveness makes robot tracks an essential component of modern manufacturing strategies.

Conclusion: Embrace the Future of Manufacturing

In conclusion, robot tracks and robotics in manufacturing are crucial in transforming production lines. The EVS Robot Walking Rail exemplifies the potential of this technology. Robot tracks enhance robotic mobility, significantly boosting efficiency and productivity. Integrating robot tracks in robotics in manufacturing ensures precision, flexibility, and scalability. Invest in robot tracks and robotics in manufacturing to future-proof your operations and drive long-term success.