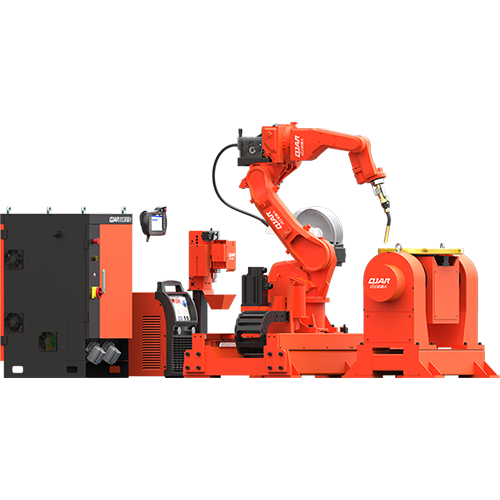

Palletizing robots are in the front of this revolution in robotics in manufacturing, which is taking place quickly. These sophisticated devices are now necessary for enhancing productivity, increasing accuracy, and automating repetitive processes. Heavy-duty palletizing robots from EVS, such as the QJRB180-1 and QJRB800-1, are revolutionizing the way companies handle their industrial operations. These robots are ideal for sectors with difficult logistical requirements because of their ability to handle high loads. They have a payload capacity of 180 kg and 800 kg, respectively.

Robotics’ Potential in Manufacturing

Robotics in manufacturing is essential for current production line optimization. Robots that palletize materials have become more popular because they automate material handling, which lowers human error and increases accuracy. With a reach of 3153mm, the QJRB180-1 provides a flexible option for transferring goods from manufacturing lines to shipping zones. These kinds of palletizing robots make sure that items are stacked and arranged properly, which improves operational flow.

These robots’ automation lowers labor expenses and boosts worker safety in production settings. These robots can operate around the clock, assuring continuous operations and greater efficiency, by tackling heavy-duty activities like palletizing. Because of this, robotics in manufacturing is becoming a crucial component of contemporary company plans.

QJRB180-1: Revolutionizing Palletizing

One of the most sophisticated palletizing robots made for demanding tasks is the EVS QJRB180-1. This robot’s 180kg payload capacity and 3153mm reach make it ideal for handling bulky, big objects. With its precise motion control, the QJRB180-1 can pick, put, and stack objects with exceptional accuracy. Because even little mistakes may stop whole production lines, this degree of accuracy is crucial in robotics in manufacturing.

The QJRB180-1 is outfitted with cutting-edge sensors and control technologies to guarantee seamless and effective functioning. It is extremely adaptable in a variety of sectors since it can be configured to undertake different palletizing jobs. This palletizing robot enhances efficiency by optimizing processes by moving large goods and arranging things on pallets.

The QJRB800-1’s Capabilities for Palletizing robots

Among the palletizing robots from EVS, the QJRB800-1 is another formidable machine. This robot, which has an astounding payload capacity of 800 kg and a reach of 3159 mm, is made for the most demanding logistical businesses. Because of its large payload capacity, it is a great choice for industries like manufacturing, construction, and automotive where the rapid and effective transportation of big goods is required.

The capacity to bear heavy loads is essential for robotics in manufacturing as it helps to eliminate the requirement for manual labor. With unparalleled accuracy, the QJRB800-1 completes this work, freeing up the producer to concentrate on increasing output. The robot’s capacity to operate nonstop without getting tired guarantees that manufacturing cycles don’t stop, which greatly boosts productivity.

How Robots That Palletize Drive Efficiency

Palletizing robots are built to enhance efficiency, which is a crucial parameter in robotics in manufacturing. The QJRB180-1 and QJRB800-1 increase efficiency by mechanizing the labor-intensive operation of stacking, arranging, and moving cargo. These robots are able to work around the clock, so there is never a pause in operations. More output rates, lower labor expenses, and fewer human mistakes result from this enhanced efficiency.

Palletizing robots can do intricate operations that would be difficult for human personnel to complete, particularly when large loads are involved, with precision control. These robots’ automation improves safety by removing the need for workers to do physically demanding tasks, which lowers the possibility of workplace accidents.

In summary

In conclusion, by automating labor-intensive operations, palletizing robots like the EVS QJRB180-1 and QJRB800-1 are transforming robotics in manufacturing. These robots save personnel expenditures, increase operational efficiency, and precisely execute challenging palletizing operations. These robots will be vital in determining the direction of production and logistics as firms embrace automation. Their exceptional payload capacity, sophisticated control mechanisms, and uninterrupted functionality render them crucial for enterprises seeking to maximize their production processes and maintain their competitiveness in the worldwide marketplace.

Arabic

Arabic Bulgarian

Bulgarian Czech

Czech Dutch

Dutch English

English Finnish

Finnish French

French Georgian

Georgian German

German Greek

Greek Hungarian

Hungarian Italian

Italian Japanese

Japanese Korean

Korean Lithuanian

Lithuanian Myanmar (Burmese)

Myanmar (Burmese) Persian

Persian Polish

Polish Portuguese

Portuguese Romanian

Romanian Russian

Russian Serbian

Serbian Slovak

Slovak Spanish

Spanish Swedish

Swedish Thai

Thai Turkish

Turkish Ukrainian

Ukrainian Vietnamese

Vietnamese