The use of gear boxes and welding turntables in industrial welding provides unparalleled accuracy and efficiency. Together, these parts improve welding processes’ speed and accuracy, particularly in automated systems, by streamlining operations. The welding turntable can revolve smoothly and steadily because a gear box is used to guarantee the proper torque and speed. This article explores the ways in which welding turntables and gear boxes improve industrial welding productivity.

The Function of Gear boxes in Turntable Welding

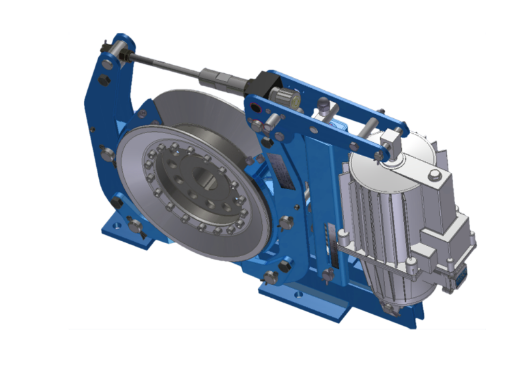

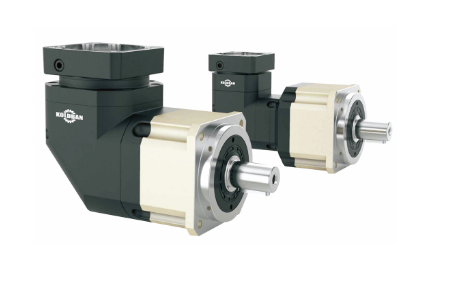

An essential component of welding automation torque and speed control is a gear box. Its main purpose is to increase torque while decreasing motor speed, giving the welding turntable the power it needs to rotate complicated and heavy workpieces steadily. Even in the most demanding welding operations, accuracy is maintained when the gear box and welding turntable are merged. By guaranteeing seamless rotating speed changes, the gear box reduces mechanical stress, which is essential for avoiding welding process flaws.

Benefits of Welding turntables and Gear boxes Together

For industrial applications, integrating a gear box and welding turntable offers several benefits. First off, regardless of the weight or intricacy of the workpiece, the gear box supplies the mechanical power required for the welding turntable to revolve steadily. This removes the possibility of uneven welding, which is especially important for precision-based operations. Second, by improving automation, the combination makes it possible for welding systems to carry out operations without the need for human interaction. Because the automated system can consistently and accurately handle repeated welds, efficiency is boosted.

Utilizations in Industrial Welding on a Large Scale

Large-scale welding processes benefit greatly from the combination of gear boxes and welding turntables. These parts are essential to the handling of large workpieces in industries such as pipeline construction, car manufacture, and shipbuilding. Continuous, steady rotation is made possible by a welding turntable, and the gear box modifies speed and torque to fit the size of the material. This arrangement lowers the possibility of weak spots or other flaws in the weld by guaranteeing that even huge components can be welded precisely. The gear box is perfect for these heavy-duty applications because it gives the power required for continuous performance.

Increasing Welding Automation using Turntables and Gear boxes

The integration of gear boxes and welding turntables is at the core of the increasing automation of welding operations. Welding turntables automate the rotating movement of workpieces, removing the need for ongoing manual adjustments and enabling laser welding robots to operate with extreme precision. Regardless of the object’s size or weight, the gear box guarantees smooth and constant rotation. This lowers downtime, boosts output, and enables producers to finish massive production runs with little mistake.

By limiting human interaction, the automation of welding operations through the use of gear boxes and welding turntables also lowers labor expenses. These technologies assist industry in reaching their production targets while upholding high standards of quality thanks to uniform welding and fewer errors.

Welding turntables and Gear boxes: The Future of Welding

Gear box and welding turntable relevance will only increase as companies continue to adopt more automated solutions. The capabilities of these components will be further enhanced by advancements in robotics and control systems. Gear box efficiency is expected to increase in the future, providing more power output while using less energy. As this is going on, welding turntables will develop further, offering even more accurate rotating control for a greater range of welding applications.

In summary

In conclusion, improving industrial welding efficiency requires a combination of gear boxes and welding turntables. The welding turntable offers steady rotation for precise welding, and a gear box makes sure it runs at the right torque and speed. When combined, they allow for seamless, automated welding procedures that raise output while cutting expenses. The use of gear boxes and welding turntables will continue to be crucial to the future of industrial manufacturing as more automated welding systems are adopted by companies.