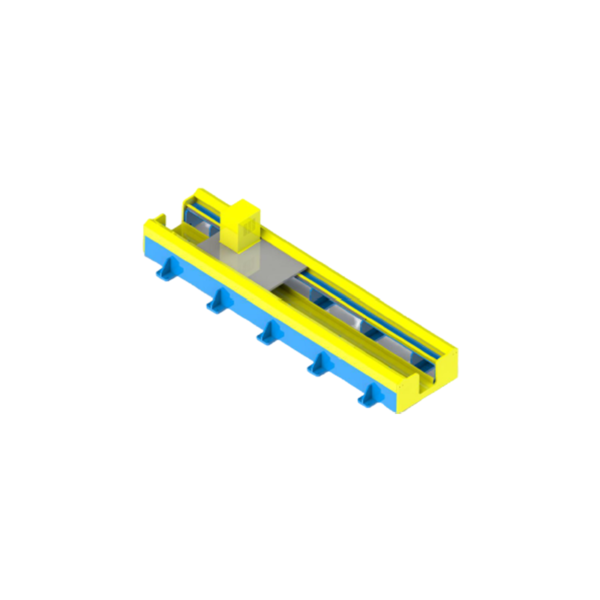

Unmatched performance, adaptability, and accuracy are provided by the combination of robot tracks and motorgear boxes in industrial automation. Together, these two components maximize robot mobility and performance, resulting in smooth industrial processes. Robot tracks improve mobility by enabling robots to move through large areas with ease, while motorgear boxes supply the torque and speed changes required for effective power transfer.

Robot tracks’ Function in Improving Mobility

Robot tracks are essential for allowing robots to navigate wide spaces without assistance from humans. Robot tracks increase operational flexibility in industries like manufacturing, storage, and logistics by increasing a robot’s range of motion. Robots travel smoothly on robot tracks, removing the need for human adjustment and resulting in lower downtime and increased production.

Robot tracks provide even higher accuracy when used with motorgear boxes. Robots are able to move smoothly along their predetermined courses regardless of the size or weight of the workpiece being handled because the motorgear boxes make sure that the power output is optimum.

How Power Transmission Is Improved by Motorgear boxes

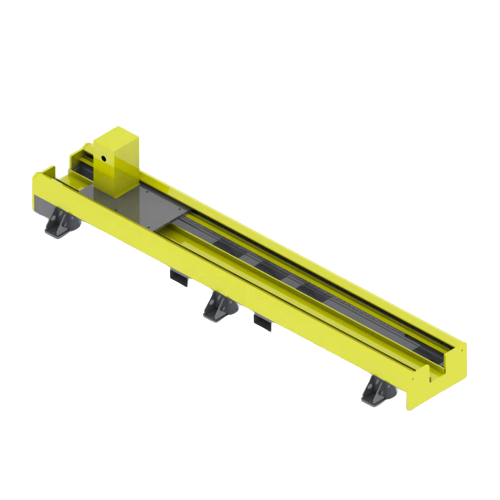

In robotic systems, motorgear boxes are essential for controlling torque and speed. The robot can travel efficiently on the robot tracks thanks to the motorgear boxes, which can change the torque and motor speed. This is crucial for moving big objects, as maintaining smooth, steady movement requires the correct ratio of power to speed.

Robotic systems might have inefficiencies like jerky movements or system overloads if motorgear boxes weren’t there to offer the necessary power regulation. In order to ensure smooth operations, motorgear boxes ensure that the robots may move fluidly along the robot tracks.

Combining Motorgear boxes with Robot tracks Has Advantages

For industrial processes, the combination of robot tracks with motorgear boxes has several advantages. In order to guarantee that robots may travel on robot tracks without experiencing any performance problems, motorgear boxes first control the power supply. As a result, energy is used more effectively, and robot functioning is improved. Second, longer mobility is made possible by robot tracks, which lets robots explore more regions in warehouses or factories. As a result, the automation system’s total productivity increases.

Industrial robots can accomplish their jobs with increased accuracy and efficiency thanks to robot tracks and motorgear boxes, which optimize both mobility and power transfer. This improves overall operational performance.

Logistics and Manufacturing Applications

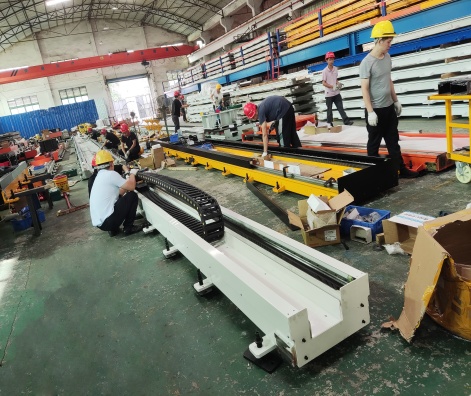

Robot tracks and motorgear boxes are vital parts of automation-dependent businesses like manufacturing and logistics. Robots are frequently needed in these settings to move materials or carry out assembly duties across large distances. Robot tracks increase the robots’ operating range, and motorgear boxes control their motions so they may effectively tackle complicated jobs and big loads.

Robots can roam storage facilities, pick up and transport items, and manage complicated activities without the assistance of a person thanks to the integration of robot tracks and motorgear boxes in smart logistics. This automation lowers the possibility of mistakes in material handling and transportation while also increasing efficiency.

Cutting Operational Expenses and Increasing Dependability

The lower operating expenses are one of the main benefits of employing robot tracks and motorgear boxes. Businesses may reduce the number of robots required for their operations by giving robots the ability to cover greater areas and do jobs more quickly. Further cost reductions are achieved since motorgear boxes‘ power management guarantees that the robots don’t use excessive amounts of energy.

Furthermore, the use of motorgear boxes and robot tracks improves the dependability of robotic systems. Robots on tracks move more smoothly and consistently, which lowers the chance of mechanical failures and minimizes downtime and maintenance needs.

Industrial Automation in the Future Using Robot tracks and Motorgear boxes

Robot tracks and motorgear boxes will play an increasingly important role as companies continue to adopt more sophisticated automation technology. Future developments in these parts should result in systems that are better capable of handling more complicated jobs and are energy-efficient and efficient. Businesses can guarantee that their robotic systems function flawlessly in a variety of industrial applications by fusing the mobility of robot tracks with the power-regulating capabilities of motorgear boxes.

In summary, optimizing the effectiveness of robotic systems in industrial processes requires the integration of motorgear boxes and robot tracks. These parts allow robots to work more efficiently by improving mobility and guaranteeing accurate power transfer, which eventually results in more efficient and economical production and logistical processes.