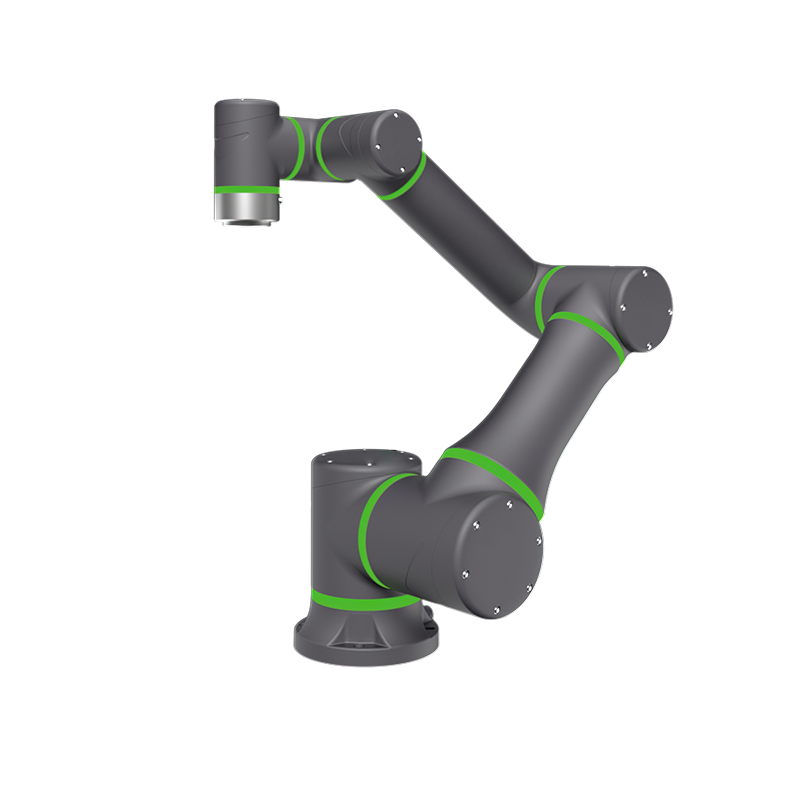

Pick and place robots’ Significance in Contemporary Automation

Pick and place robots are crucial for doing repetitive jobs quickly and accurately in the fast-paced world of automation. These pick and place robots are excellent in moving and lifting goods in packaging, electronics, and assembly sectors. When paired with robot tracks, however, their performance is much improved since they enable the robots to accomplish jobs across wider regions and with greater range of motion. Robot tracks and pick and place robots work together to improve efficiency and output.

How Robot tracks Boost Pick and Place Operations Efficiency

with enabling them to travel along a predetermined course and cover more land than a fixed arrangement, pick and place robots‘ capabilities are expanded with the inclusion of robot tracks. By allowing the robot to move between several workstations or assembly lines without assistance from a human, this integration increases efficiency. Robot tracks maximize production and reduce the amount of time spent manually adjusting the robot by providing pick and place robots with the mobility required to manage intricate, large-scale activities.

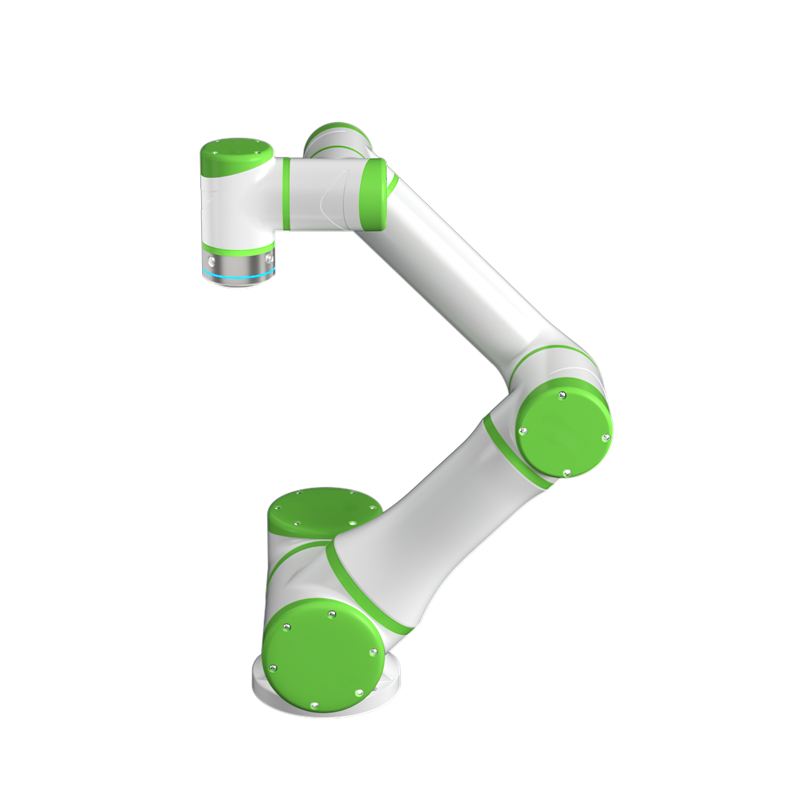

Pick and place robots on Robot tracks: Increasing Accuracy

Robot tracks significantly improve the accuracy of pick and place robots. Robot tracks give robots a steady, regulated motion route that enables them to stay accurate even in hectic situations. This combination guarantees that the pick and place robots can do complex jobs or handle sensitive materials with great precision, which makes them perfect for sectors where accuracy is essential, like the manufacture of pharmaceuticals or electronics.

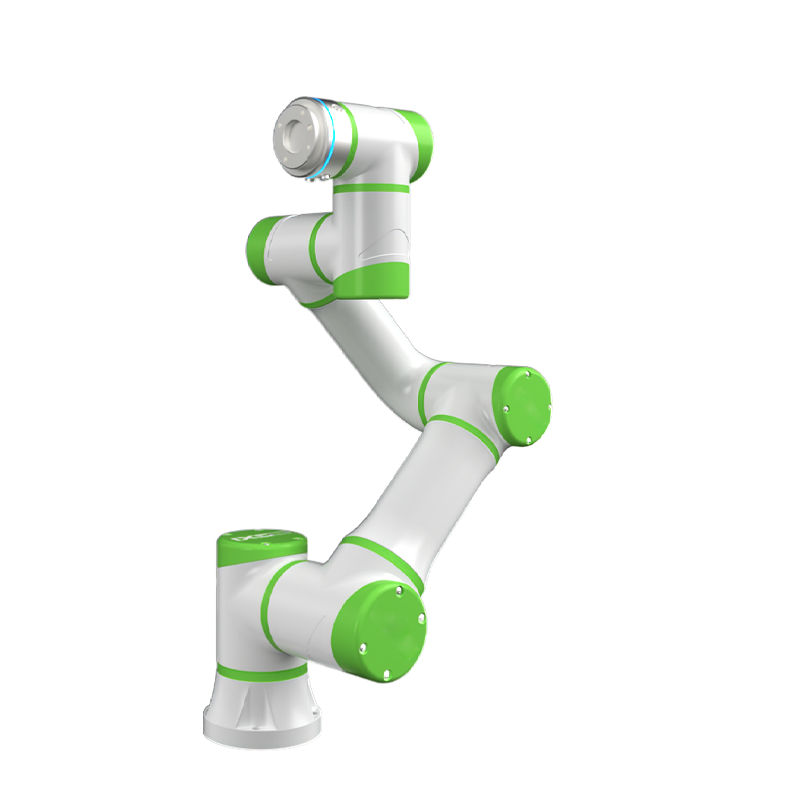

The capacity to adjust and be flexible as production layouts change

When production demands change, firms can find a flexible solution using pick and place robots and robot tracks. Robot tracks enable the robots to move between various assembly areas or workstations, allowing them to adapt quickly to new duties. Because of its flexibility, operations may be changed or production scaled up without requiring a whole setup redesign. Businesses may continue operating smoothly even as their manufacturing needs change by combining pick and place robots with robot tracks.

Optimizing Space Use in Industrial Environments

Because floor layouts are limited in big industrial plants, the integration of robot tracks with pick and place robots helps maximize available space. Robot tracks eliminate the requirement for fixed workstations and provide room for additional equipment by enabling pick and place robots to go along predefined pathways. Workflow is enhanced and operational expenses are reduced by this effective use of space. The use of pick and place robots in conjunction with robot tracks improves overall facility management in addition to increasing productivity.

In conclusion, the use of robot tracks and pick-and-place robots in optimized operations has a promising future.

To maximize industrial processes, pick and place robots and robot tracks must work together harmoniously. This combination increases mobility, accuracy, and flexibility, enabling manufacturers to increase productivity while adjusting to shifting production demands. The combination of pick and place robots and will be essential to advancing productivity and creativity across a range of sectors as automation continues to grow. The key to maximizing the benefits of automated processes and achieving more competitiveness and success in the global economy is this potent mix.