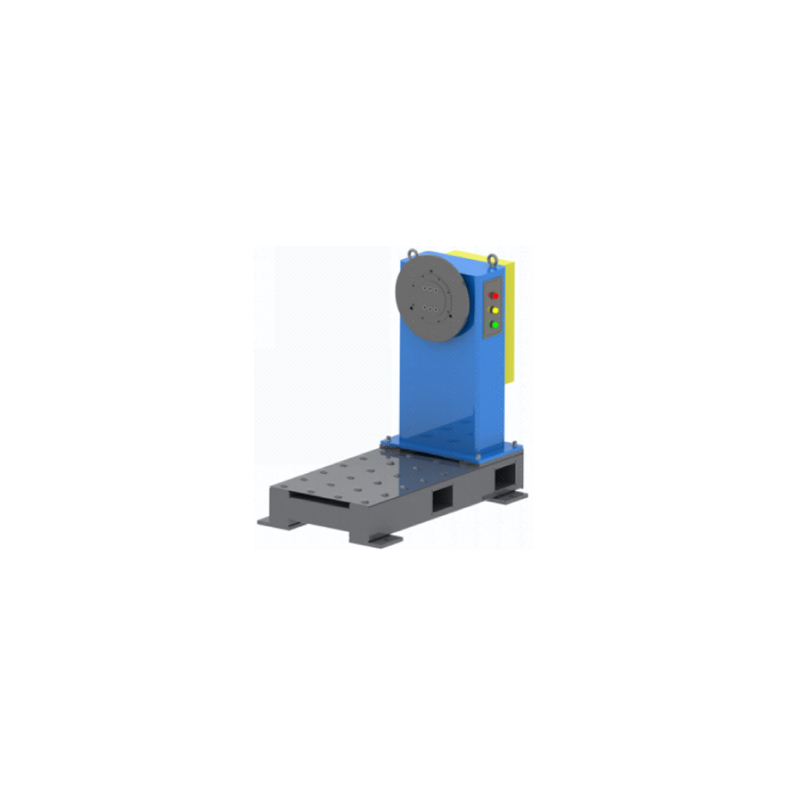

Sturdiness and Versatility of L-Type Welding positioners

It is commonly known that L-Type welding positioners are stable and adaptable. Because of its firm grasp, the workpiece is easy to rotate and position for welding. When used in conjunction with robot tracks, the L-Type welding positioner guarantees accurate and seamless mobility. The welding robot may be moved about as needed thanks to its movement on the robot tracks. It enables welders to achieve otherwise difficult angles while preserving consistent weld quality. This combination provides a welding method that strikes a compromise between accuracy and adaptability.

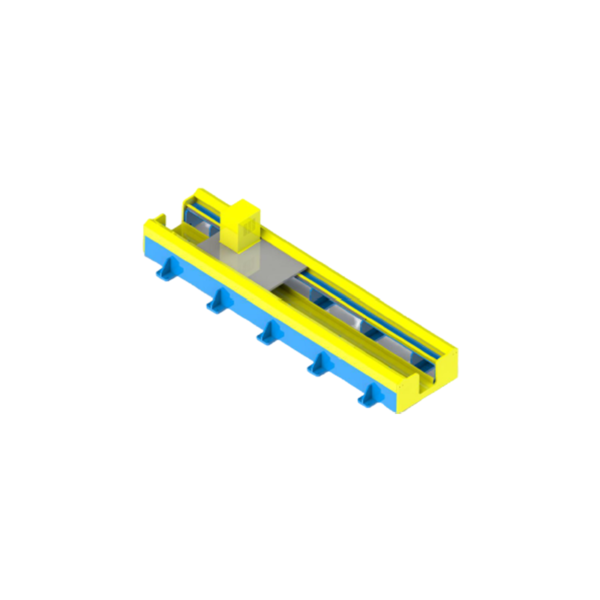

C-Type Welding positioners: The Best Flexibility for Difficult Assignments

Maximum flexibility is a feature of C-Type welding positioners, particularly when performing complex welding jobs. Their C-shaped structure allows for multidirectional mobility, improving the reach of welding robots. Even more versatility is provided by the C-Type welding positioner when used with robot tracks. Robot tracks enable welding robots to move smoothly over a workpiece’s length. In order to ensure a consistent weld across various locations, this capacity is essential for welding complex shapes. Industries that require a high degree of versatility are ideal for the C-Type model.

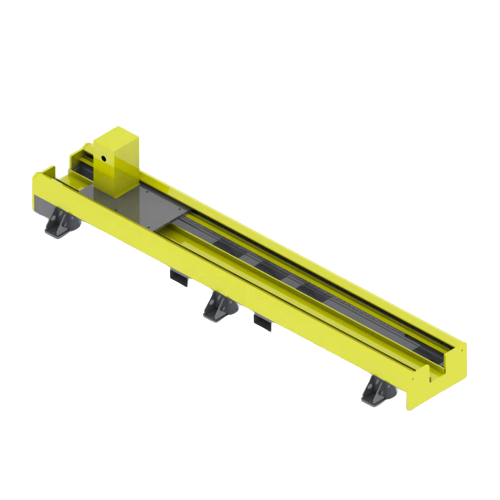

Enhancing Welding Automation with Robot tracks

An important factor in improving automation during welding processes is robot tracks. Robot tracks increase the work envelope of robots by allowing welding robots to follow a predetermined course. Robot tracks, when used in conjunction with L-Type or C-Type welding positioners, allow robots to carry out activities that call for movement along several axis. The necessity for manual welding equipment repositioning is eliminated by this dynamic capability. Robot tracks are integrated to enable continuous welding operations by decreasing downtime and increasing productivity.

Integrating Robot tracks with Welding positioners for Smooth Operations

Welding positioners and robot tracks can be integrated to produce a smooth welding process that offers flexibility and stability. Heavy workpieces may be supported steadily by L-Type welding positioners, and controlled movement is possible with robot tracks. Robot tracks enable access to hard-to-reach areas for C-Type welding positioners, guaranteeing the accuracy needed for intricate welding. This combination guarantees that all parts of the workpiece may be accessed without operator intervention, improving operating efficiency.

Applications across a Range of Sectors

In many different sectors, welding positioners and robot tracks are used together. Robot tracks enable the exact movement of welding robots, while L-Type welding positioners assist in the handling of large frames in car manufacture. In the aerospace industry, where intricate parts require precise welding, C-Type welding positioners are very useful. Robot tracks provide welding robots flexibility and ensure that they can move effectively. Delivering high-quality welds for a variety of industrial purposes requires this combination.

Improved Safety and Productivity

In welding settings, the use of robot tracks and welding positioners may greatly increase safety and productivity. Operators may concentrate on supervising the welding process as welding positioners eliminate the requirement for manual repositioning. By ensuring that robots can move smoothly without operator assistance, robot tracks help to minimize exposure to dangerous situations. This combination reduces the dangers connected with manual handling and helps to establish a safer working environment. Furthermore, welding positioners and robot tracks allow for faster, more reliable welding, which boosts output.

In conclusion, utilizing welding positioners and robot tracks to maximize flexibility

In conclusion, flexibility and efficiency in welding processes are greatly increased by integrating robot tracks with L-Type and C-Type welding positioners. While C-Type welding positioners give flexibility for complex welds, L-Type devices offer stability. Robot tracks enable welding robots to move precisely and smoothly, complementing both. An effective, automated welding process that optimizes productivity, quality, and safety in welding jobs is produced by welding positioners and robot tracks working together. It makes sense for enterprises looking to produce reliable, high-quality welds to invest in this combination.