Maintaining an advantage in the highly competitive manufacturing world of today requires optimizing productivity. This may be accomplished most efficiently by using welding positioners with motorgear boxes. Welding processes across sectors are becoming more flexible, precise, and efficient thanks to these cutting-edge technology. This paper examines the mutual benefits of welding positioners and motorgear boxes and how combining the two may improve your manufacturing procedures.

Knowledge of Motorgear boxes and Welding positioners

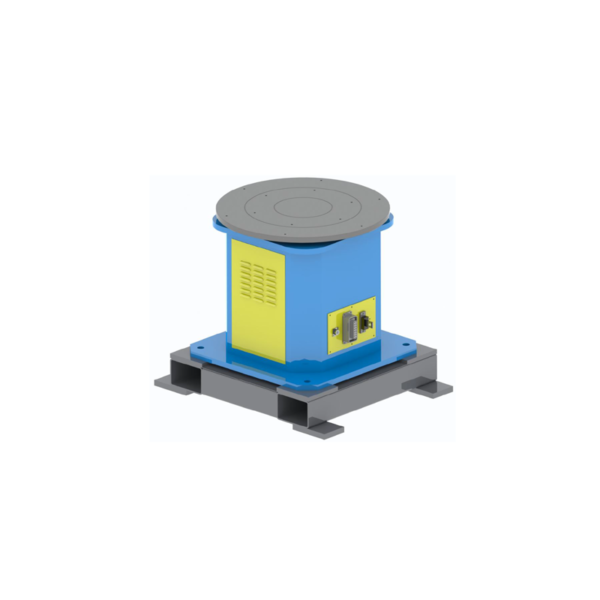

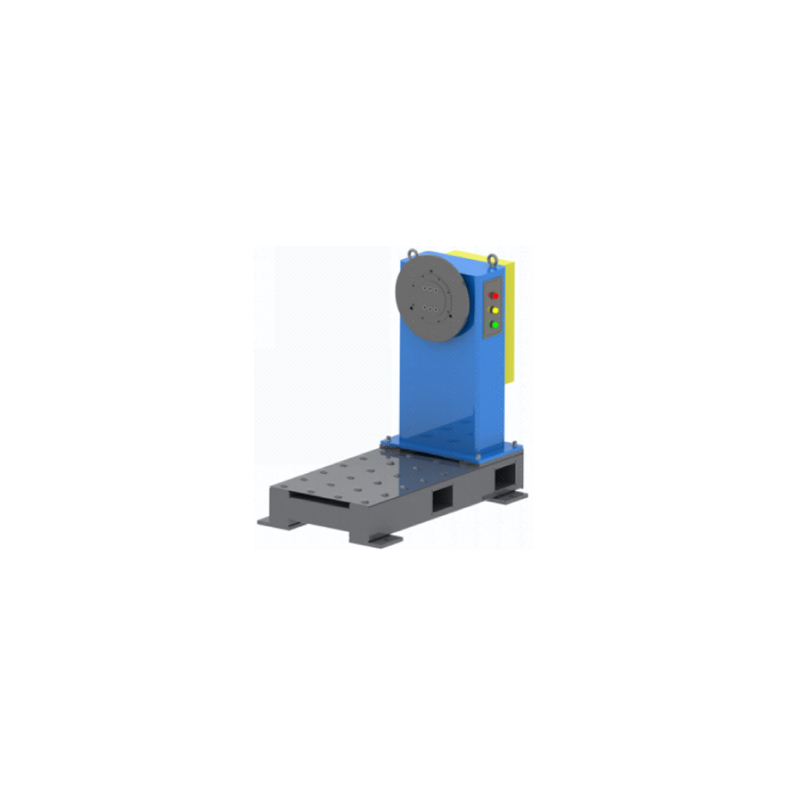

Devices called welding positioners are made to hold and rotate workpieces while welding. With the help of these devices, welders may consistently produce high-quality welds by holding the workpiece in the ideal position. Large or heavy objects that need accurate alignment for effective welding benefit greatly from them.

With motorgear boxes, however, the torque required to rotate or move components effectively is delivered by mechanical mechanisms. The precise and long-lasting operation of machines depends on these gearboxes, which convert motor power into rotational motion. The use of motorgear boxes into welding positioners improves the workpiece’s movement and control, guaranteeing more precise welding processes.

The Function of Motorgear boxes in Improving Positioning Welders

A notable improvement in performance may be obtained by integrating motorgear boxes with welding positioners. With the help of these gearboxes, positioners can operate with more accuracy because to their steady and strong rotating motions. Also, motorgear boxes can increase rotational speed and efficiency, which is important for high-throughput manufacturing processes.

Handling heavier and bigger workpieces is made simpler by motorgear boxes, which regulate torque and rotation speed. Additionally, they provide more seamless transitions between various welding positions, which lowers the possibility of mistakes and rework. The outcome is a more dependable and effective welding application solution offered by welding positioners with motorgear boxes.

Better Accuracy and Precision

Together, welding positioners and motorgear boxes provide increased accuracy, which is essential in sectors where quality assurance is critical. Even at high speeds, the workpiece is positioned precisely and steadily thanks to motorgear boxes. To guarantee that the welds are reliable and satisfy the necessary requirements, this degree of accuracy is essential.

Reduced Downtime and Increased Efficiency

Additionally, welding positioners and motorgear boxes work together to improve operating efficiency. Because motorgear boxes provide dependable and smooth rotating motion, welding processes may continue uninterrupted. High-volume production settings require minimal downtime and maximum production uptime, which this continuous operation provides.

Workers can also automate procedures and lessen the need for manual adjustments by programming welding positioners with precise rotating rates and motions. By reducing human error and expediting the welding process, this raises the welding operation’s total productivity.

Adaptability and Versatility in Applications for Welding

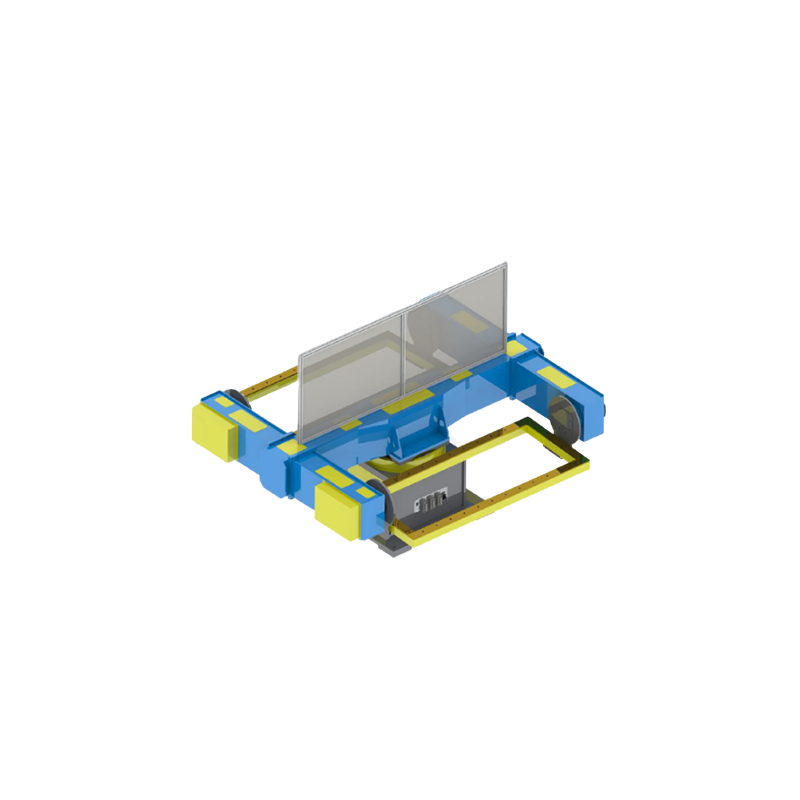

An additional significant advantage of combining welding positioners with motorgear boxes is the enhanced adaptability and versatility of the welding process. Because motorgear boxes may be made to accommodate different torque specifications and rotating rates, welding positioners can be employed in a variety of settings, ranging from small-scale repairs to large-scale production.

In sectors such as pipe welding, heavy machinery, and shipbuilding, for example, where intricate and huge pieces must be welded, welding positioners with motorgear boxes can be modified for usage. The positioners’ motion capabilities may be adjusted to process a variety of components more effectively, which increases operational flexibility.

Economies of scale and long-term savings

Long-term savings are significant even if purchasing welding positioners with motorgear boxes may appear expensive at first. Businesses may rapidly recover their investment in welding operations by boosting production, decreasing the likelihood of faults, and enhancing efficiency. Because motorgear boxes increase welding positioners‘ longevity, less repairs and maintenance are required, which further reduces operating costs.

Decreased labor expenses are another benefit of less downtime and rework. Businesses may more efficiently deploy resources when welding processes are more reliable and efficient since less physical labor is required. More competitiveness in the market and a sizable return on investment (ROI) are possible outcomes of these savings over time.

Final Thoughts

One of the most effective ways to increase output and efficiency in welding processes is to integrate motorgear boxes into welding positioners. Through improved accuracy, increased adaptability, and long-term cost savings, this integration can assist producers in satisfying the growing need for high-quality, high-speed welding. Welding positioners with motorgear boxes offer the ideal option to optimize your welding operations, whether you are working with big, heavy components or need to increase the precision of your welds.