Thanks to sophisticated automation systems, the production scene of today is rapidly changing. The incorporation of motorgear boxes with robotics in manufacturing systems is a crucial component of this development. These elements are crucial for maximizing robot performance and guaranteeing accuracy and efficiency in challenging industrial operations. In this article, we look at how motorgear boxes are reshaping robotics in manufacturing and empowering producers to reach unprecedented productivity levels.

Motorgear boxes’ Function in Robotics Manufacturing

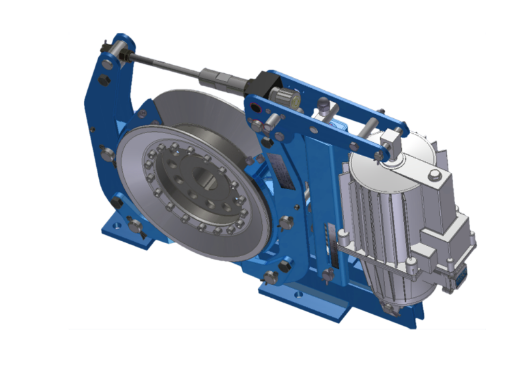

Motorgear boxes are made to maximize torque and speed in order to improve motor performance. These gearboxes, which are employed in robotics in manufacturing, guarantee the effective operation of the robotic components by striking the ideal ratio of torque to speed. For high-precision jobs like welding, assembly, or material handling, industrial robots must strike the ideal balance between speed and control. Manufacturers may guarantee that their robots can do both delicate and heavy-duty tasks with ease by using motorgear boxes.

Increasing Productivity with Optimal Torque and Speed

By enabling robots to adjust to varying load needs, the integration of motorgear boxes in robotics in manufacturing contributes to increased efficiency. Robots can carry out duties like lifting large things or performing precise moves thanks to gearboxes, which assist boost torque while decreasing speed. In production settings, where robots must do a variety of jobs with different needs, this skill is essential. By ensuring that robotic systems can adjust to these demands, motorgear boxes improve overall productivity and save wear on the mechanical parts.

Increased Accuracy in Production Processes

Precision is essential for preserving product quality and cutting down on material waste in robotics in manufacturing. By giving robotic arms consistent, regulated motion, motorgear boxes are essential to improving this accuracy. When using motorgear boxes, the robot moves with the required accuracy whether it is welding, assembling complex parts, or putting products on a manufacturing line. This accuracy lowers the possibility of mistakes, producing better goods with fewer flaws, which eventually increases the manufacturing process’s profitability.

Flexibility in a Variety of Manufacturing Uses

Because of its adaptability, motorgear boxes are a great addition to robotics in manufacturing. Gearboxes are appropriate for a variety of production operations because they may be customized to meet the unique requirements of various applications. Motorgear boxes enable the robots to work as efficiently as possible, whether they are on a high-speed assembly line or a heavy-duty welding station. This adaptability guarantees that the same robotic systems may be utilized for various tasks without requiring significant reconfiguration, which is especially crucial for businesses wishing to automate various production phases.

Economical and Long-Term Dependability

In addition to increasing performance, integrating motorgear boxes with robotics in manufacturing also lowers costs and increases long-term dependability. By maximizing speed and torque, gearboxes lessen the pressure on motor components, resulting in reduced wear and tear and cheaper maintenance expenses. Motorgear boxes‘ improved accuracy also results in fewer errors and material waste, which lowers total costs. Because of their efficacy, dependability, and affordability, gearboxes are a crucial component of robotic systems for manufacturers.

Encouragement of Innovation in Manufacturing

The need for creative solutions to boost productivity and efficiency is becoming more and more obvious as industrial processes continue to change. At the heart of this breakthrough are motorgear boxes, which allow the creation of more intelligent and effective robotics in manufacturing. In an industry that is evolving quickly, motorgear boxes are helping businesses remain competitive by allowing robots to complete jobs more quickly, precisely, and flexibly. For firms hoping to prosper in the era of automation, including gearboxes into robotic systems is therefore not only an improvement but also a must.

In conclusion

To sum up, the incorporation of motorgear boxes with robotics in manufacturing is revolutionary for sectors looking to increase productivity, accuracy, and economy. These gears improve robot performance, enabling them to effortlessly manage a variety of intricate production jobs. Motorgear boxes play a crucial part in contemporary industrial systems by offering optimal torque, precise control, and long-term dependability. Purchasing motorgear boxes for their robotic systems is a calculated decision that will spur future innovation and productivity for businesses trying to remain ahead of the competition.