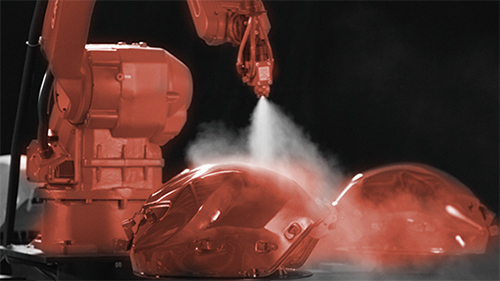

By 2025, robots will revolutionize the industry by automating complicated painting tasks. They do so with speed and precision. These machines are capable of delivering consistent, high-quality results that manual methods cannot. By reducing material waste and ensuring consistency, they increase efficiency throughout production lines. The explosion-proof design allows safe operation in hazardous areas, protecting workers from harmful chemical.

Globally, the market for paint robots will be worth $4.5billion in 2025. This growth is driven by industries like aerospace, automotive, and construction. These robots set new standards for safety and environmental responsibility with AI Integration. You’ll learn how painting robots can transform industrial painting to a seamless experience as you examine the different types available.

Paint Robots Overview

What are painting robots?

Paint robots can be automated machines that apply coatings with accuracy and consistency. These robots are excellent at tasks that require uniform surfaces, like painting cars, aircraft and consumer goods. They reduce human error by automating the process of painting. Paint robots are used by industries like aerospace, automotive, and manufacturing to produce flawless results.

| Industry | Specific Use Case |

|---|---|

| Automobile | To achieve a perfect finish, apply uniform coats to the vehicle. |

| Aerospace | Application of specialized coatings on aircraft components with high precision. |

| Manufacturers | Paint furniture and apply protective coatings on electronic devices. |

| Consumer Goods | Use of various coatings, including water-based coatings and specialty coatings. |

Key Features and Components

The functionality of painting robots is enabled by several key components. The base ensures the robot runs smoothly. The multiple degrees of freedom arm allows for flexibility and precise positioning. The actual painting is done by the end effector. This can be either a paint pump or a spray gun.

| Component | Description |

|---|---|

| Base | The robot’s foundation, which provides stability and support. |

| Arm | The painting tool is designed to allow for multiple degrees of flexibility. |

| End Effector | Depending on the design, the part that does the painting can be either a sprayer or a pump and mixer. |

How painting robots work

Programming and advanced design capabilities are used to operate painting robots. The internal cables and tubes of paint ensure smooth operation, without interference from outside. These robots can be programmed with software to follow complex trajectory, ensuring accurate application of coatings. They are more efficient when they receive regular maintenance.

- Design Features Internal cables and paint tubes allow for smoother operation.

- Programming capabilities: Advanced software enables precise trajectory programming.

- Maintenance practices: Routine inspection and maintenance is essential to ensuring consistent performance.

Understanding how painting robots function will help you appreciate their importance in the transformation of industrial painting processes.

There are many different types of painting robots.

Mounting Methods

Floor-Mounted painting robots

The most common industrial painting robots are floor-mounted. These robots, which are mounted on the ground, provide stability and precision when performing tasks that require consistent painting. They can reach large surfaces and handle heavy loads with ease thanks to their sturdy base. These robots are ideal for industries such as automotive and aerospace that require high-volume operations.

Wall-Mounted painting robots

The flexibility of wall-mounted robots allows them to save space and still be flexible. These robots can be mounted on vertical surfaces and are ideal for small facilities. They can reach areas that are difficult to reach and ensure uniform coverage. These robots are especially useful in areas where space is a concern.

Ceiling-Mounted Paint Robots

These robots are mounted on the ceiling and operate from above. They offer a workspace that is unobstructed. These robots are excellent at painting large objects such as aircraft or construction equipment. They reduce the interference caused by other machines on the ground because they work from the ceiling. They are a valuable asset for industries that require extensive painting.

Mobile Painting Robots

Mobile painting robots offer unmatched versatility in industrial painting. These robots adapt to different tasks and environments by moving autonomously. They are equipped with sensors that allow them to navigate through complex spaces, and apply paint precisely. Mobile robots are ideal for projects that require flexibility, like painting infrastructure or large scale construction.

Coating Application Technologies

Spray Painting Robots

Air atomization is used by spray painting robots to evenly apply paint. This method is durable and cost-effective, which makes it ideal for general-purpose uses. It may not be able to provide the consistency needed for specialized tasks.

Electrostatic painting robots

Electrostatic robots are highly efficient because they break down liquids to fine particles. This reduces overspray, and paint will adhere to surfaces that are positively charged. It is highly effective but requires extra programming and costs more.

Powder Coating Robots

Robots that apply powder coatings to surfaces use dry powder, which is then heated to create a durable finish. This method is eco-friendly and produces little waste. These robots are ideal for tasks that require robust, long-lasting coatings.

Dip Coating Robots

The robots dip objects in a paint solution to ensure complete coverage. This is the best method for coating items with complex shapes, or those that require a uniformly thick layer. This method is used by industries such as electronics and appliances.

| Atomization method | Benefits | Disadvantages |

|---|---|---|

| Air Atomization | Cheapest atomizer, high durability. | Spray is less consistent and not suitable for every application. |

| Electrostatic Atomization | The product adheres to surfaces and is effective at breaking down liquids. | Complex design, requires extra programming, expensive. |

| Ultrasonic Atomization | Produces fine spray patterns, negligible overspray. | Complex design, requires extra programming, expensive. |

Robotic Arm Types

Articulated painting robots

These robots are flexible and precise, with multiple joints. These robots can be used for jobs that require intricate movements such as painting small parts or detailed designs.

SCARA Painting Robots

The SCARA (Selective Compliance Assembler Robot arm) painting robots are specialized in horizontal movements. These robots are perfect for repetitive tasks that require speed and accuracy. For example, painting flat surfaces or assembly line.

Cartesian Painting Robots

Cartesian robots are able to move with ease and precision on three linear axes. These robots work best for jobs that require a consistent and linear paint application.

Delta Painting Robots

Delta painting robots are triangular in configuration and achieve high speed operations. They are lightweight and ideal for jobs that require rapid painting, like packaging or consumer products.

- The robotic arm that you select will impact the performance and flexibility of your paint robot .

- Cartesian arms are better for linear work than articulated arms.

- The robot’s performance is determined by features such as payload, reach and speed.

Paint Robots: Applications

Automotive and Aerospace

In the aerospace and automotive industries where efficiency and precision are key, painting robots are an essential tool. These robots are used in the automotive industry to streamline production. They do this by eliminating paint overspray, and allowing customized designs with just one pass. ABB PixelPaint, for example, ensures that every vehicle has a perfect finish. This reduces waste and increases productivity.

FANUC’s P350iA paint robots are able to apply specialized coatings in the aerospace industry with incredible accuracy. These robots can perform multiple tasks including surface preparation and sanding, which reduces the amount of solvent used and speeds up painting. Automating these processes allows you to achieve consistent results, while maintaining safety standards.

Electronics and Appliances

Paint robots improve production quality in the electronics and appliance industries by ensuring precision and consistency. These automated systems guarantee uniform paint application which is crucial for the manufacture of electronic devices and appliances. They contribute to an efficient production process by reducing waste and improving safety at the workplace.

Painting robots can deliver finishes of high quality that satisfy the needs of modern consumers. They are indispensable for industrial automation because of their ability to accurately coat complex surfaces. These robots are essential for ensuring that every product is up to standard, whether you’re manufacturing smartphones or fridges.

Construction and Infrastructure

The combination of speed, safety, and accuracy makes painting robots a revolutionary tool for construction and infrastructure. These robots are superior to manual methods for large-scale industrial paint jobs, both in terms of efficiency and quality. The advanced technology ensures precise control of spray patterns and paint use, ensuring consistency while reducing waste up to 30%.

can improve safety by minimising human exposure to hazardous environments . The continuous operation of painting robots reduces labor costs while increasing productivity. These robots are reliable for any project, whether you’re painting bridges, pipelines or buildings.

Painting robots transform industries with their unmatched precision and efficiency.

Furniture and Consumer Goods

By automating tasks requiring precision and consistency, painting robots are revolutionizing the furniture and consumer products industries. These robots will increase production efficiency and maintain high standards. They are increasingly used in factories for spraying paints, sanding and applying protective coatings. This change has increased productivity and reduced the need for manual labor.

These robots guarantee consistent quality for every product. They apply uniform coatings to all surfaces, whether you are manufacturing plastic or wooden consumer goods. This uniformity enhances the durability and appearance of the finished product. By optimizing the paint used, painting robots reduce waste and support sustainable practices.

Choose from many different coatings, including eco friendly finishes. These finishes are environmentally friendly without compromising on quality. Adopting painting robots will help you to create a more sustainable manufacturing process and meet consumer demand for environmentally friendly products.

In the next few years, the furniture market segment is expected to grow rapidly. Automation has made furniture production faster and more efficient. Robots can handle intricate designs and complex designs with ease. This ensures flawless results. This allows you to manufacture high-quality furniture in large quantities, which is important for a competitive market.

Paint robots are used in the consumer goods industry to coat items such as electronics, toys and household appliances. They are indispensable because they can handle different materials and shapes. Integrating these robots in your production line will help you achieve superior finishes, and keep up with the latest industry trends.

Painting robots do not only serve as tools, but also investments in efficiency, quality and sustainability.

Paint Robots: Benefits

Cost efficiency and Productivity

The use of painting robots in your business can significantly reduce costs and increase productivity. They automate the tasks and reduce labor costs. The robots also reduce material waste and save as much as 30% in paint. Over time, this efficiency can translate into significant cost savings.

| Benefit | Description |

|---|---|

| Cost savings | Automation can reduce labor costs, increase production efficiency and save money overall. |

| Production and quality improvements | Robots can ensure consistency in quality and speed while reducing waste and improving product uniformity. |

| Reduce waste | Saving money by using robotic painting. |

| Flexibility Increased | The robots can quickly be reprogrammed to perform different tasks. This saves time and money during production changes. |

The robots work continuously, without interruptions. This allows you to finish projects faster and increase your throughput. The initial cost may appear high but the savings on labor, maintenance, and materials over the long term make these robots an affordable solution for your company.

Quality and Precision Enhanced

Paint robots provide unparalleled precision and consistency. The robots apply the coatings evenly and avoid streaks or unevenness, which are common with manual methods. This precision ensures that you get a perfect finish whether you are painting furniture, electronics or vehicles.

- Robots can apply paint with greater precision and consistency than human painters.

- The coatings can be precisely applied by these machines, resulting in a higher quality finish.

- Robots can reduce the speed of downdrafts and recirculate air, which allows for precise painting on complex surfaces.

They also reduce waste and costs by using paint more efficiently. They apply coatings that are corrosion resistant and durable in industries such as aerospace. They ensure that consumer products have a high quality finish and minimal surface defects. You can get superior results by using painting robots.

Improved Workplace Safety

By reducing the exposure to hazardous substances, painting robots improve workplace safety. They can perform tasks in hazardous environments, where fumes and chemicals pose a risk to health. It reduces the risk of accidents, and creates a safer workplace for your staff.

- Reduced Exposure to Hazardous Materials

- Reduce the risk of accidents

- Safety in the workplace is improved

These robots are reliable in difficult conditions thanks to their explosion-proof design and advanced safety features. Integrating painting robots in your process will protect your workers, and make your workplace safer and more efficient.

Environmental Sustainability

Painting robots can improve the sustainability of your business. These robots ensure uniform coverage, while reducing waste. They reduce production costs by reducing overspray. The precision of this process not only increases the quality of the products, but also the environmental impact.

They also help to reduce energy consumption. Lowers the energy footprint by adjusting energy consumption to production requirements. They can operate continuously and without fatigue, ensuring consistent productivity. They are therefore an environmentally friendly choice for industries looking to reduce carbon emissions.

You can enhance sustainability even further by using eco-friendly paints on these robots. Paints that are water-based or have low VOC (volatile organic compound) reduce harmful emissions and create a healthier working environment. These coatings are in line with current environmental standards and help your business to meet regulatory requirements, while also promoting sustainability.

- The benefits of painting robots for sustainability :

- The use of uniform paint reduces the waste.

- Precision minimizes paint overspray.

- Energy efficient operation reduces energy consumption.

- Compatible with eco-friendly finishes reduces harmful emissions.

The automation of the spraying process improves workplace safety. The use of painting robots can reduce the exposure of workers to harmful chemicals and fumes. This creates a safer, more sustainable workplace. Integrating these robots in your production line will help you achieve the right balance between environmental responsibility and operational efficiency. This approach is not only beneficial to your business, but also helps create a more sustainable future.

Adopting painting robots will help you achieve sustainable manufacturing. They are a vital tool for industries that want to reduce their environmental impact because of their efficiency and precision.

The Right Painting Robot

Evaluation of Task Requirements

Understanding your needs is the first step in selecting the right paint robot. You must consider several factors when evaluating the robot to make sure it meets your needs.

- Types of painting tasks Determine whether you are working on large surfaces that require smooth movements or intricate designs requiring precision.

- Features Look for advanced features such as internal cable management software and programming software to handle complex tasks.

- Payload: Verify that the robot’s reach and payload are in line with your operational needs.

- Speed: Check the robot’s speed and ensure that it meets your production goals, without compromising on quality.

- Ease in programming: Select a robot that has an easy-to-use interface to make quick adjustments and reduce downtime.

- Cost : Take into account both the initial cost and future expenses including maintenance and energy consumption.

You can find a robot that will increase your productivity and deliver consistent results by carefully analyzing the factors listed above.

Comparing Features and Capabilities

Compare the features and capabilities to find the right painting robot for you. Begin by matching the robot’s specs with your tasks. If your project involves delicate surfaces such as glass, you should prioritize robots that have high precision and advanced programing options.

The following are the key aspects to consider when evaluating a product:

- Payload and Reach : Make sure the robot is able to handle the weight and size of your materials.

- Speed : Robots that are faster improve productivity in high-volume operations.

- Easy programming Robots with intuitive software can save time when setting up and adjusting.

- Long term costs: Take into account energy efficiency and maintenance requirements to minimize operational expenditures.

By comparing robots, you can ensure that the robot selected will maximize efficiency and quality as well as meet your needs.

Budget considerations

Budget is a key factor when choosing a robot painter. To make an informed choice, you need to consider several factors:

- The brand name of the robot arm.

- The number of axes on the robot.

- The sophistication of optical sensors and end-effectors.

- Type of atomization technologies.

- Costs of programming and integration.

Consider the total cost-of-ownership, which includes maintenance and operating expenses, as well as installation. The initial investment in a robot may be high but it can save you money over time.

The right painting robot will provide long-term value as well as operational efficiency. Make sure you carefully evaluate all your options before making a decision.

Partnership with Trusted Manufacturers

The right manufacturer can have a significant impact on your business. Trusted manufacturers offer reliable products and expert assistance, which will help you to achieve the best possible results for your business. Partnering with a reputable business gives you access to the latest technology and tailor-made solutions that are tailored to your needs.

Tip A reputable manufacturer will not only supply high-quality robotics, but can also offer guidance on how to integrate them into your production lines for maximum efficiency.

The Benefits of Working with Trusted Manufacturers

- Improved Productivity and High Quality: Reliable manufacturers create painting robots that deliver high-quality, consistent finishes. These robots are able to handle difficult surfaces and areas. They can ensure that every part of your product is coated flawlessly.

- Cost savings Reliable robots can reduce waste material and energy consumption. Precision application reduces overspray and saves you money by lowering your operational costs.

- Environmental Responsibilities: High quality robots utilize advanced technologies to reduce emissions and waste. You can reduce your environmental impact and still meet sustainability goals.

- Optimized performance: Manufacturers who have expertise in robotics will help you integrate paint robots early in the design process. It will ensure that the robots are efficient and meet your production needs.

What to look for in a manufacturer

Prioritize manufacturers with a track record of success in the industry when selecting one. Companies that provide:

- Customizable Solution: Make sure the robots are adapted to your tasks and materials.

- Comprehensive support: Select a manufacturer who offers training, maintenance and troubleshooting help.

- Advanced Features : Choose robots that have cutting-edge technology, such as explosion-proof designs or non-teaching nozzle functions.

A partnership with a trusted manufacturer can be an investment in success. Their products and expertise can help you transform your painting process, allowing you to achieve superior results and reduce costs while also reducing environmental impact.

Future Trends for Painting Robots

AI and Machine Learning Integration

AI, machine learning and transform painting robots to more intelligent, adaptive tools. These technologies enable robots to optimize the use of paint, reducing waste and lowering costs. AI-powered robotics can handle complex designs and finishes with greater precision than traditional methods.

- AI allows robots to adapt their paint application to different surfaces.

- By analyzing data, and adjusting parameters of the painting in real-time, machine learning algorithms increase efficiency.

- AI-equipped robots can perform hazardous tasks to improve workplace safety, and reduce worker exposure.

These advancements are becoming increasingly important as the demand for smarter paint solutions increases. You can achieve better results by using AI-integrated robotics while still maintaining safety and sustainability.

Note : The market for painting robots is growing rapidly due to the integration of AI. This trend will ensure that robots are at the forefront of innovation in industrial applications.

The advancements in speed and accuracy

Modern painting robots set new standards for speed and precision. You can now complete your projects more quickly without sacrificing quality. Robots can now provide customized solutions for intricate designs . This makes them ideal for industries that require precision.

- AI-powered robots optimize the paint application process to ensure minimal waste.

- Robots can now handle more complex finishes thanks to improved programming capabilities.

- Productivity is improved by faster operation speeds, particularly in environments with high production volumes.

These improvements contribute to sustainability. Painting robots reduce their environmental impact by reducing waste and overspray. These advancements will help you meet your production targets while still maintaining environmentally-friendly practices.

Tip Investing high-speed and accurate robots will ensure you remain competitive in an ever-changing market.

Collaborative robots (Cobots).

Cobots (collaborative robots) are becoming increasingly popular in the painting industry. These robots offer flexibility and safety, as they work with human operators. Cobots can be particularly useful in environments that require frequent changes or low-volume production.

- Cost-effectiveness makes Cobots accessible to small businesses.

- The user-friendly design makes it easy to program, which reduces deployment time.

- Cobots can operate with minimal protection thanks to safety features. This allows for a smoother collaboration between workers and cobots.

FANUC America, for example, has designed its CRX-10iA/L robot to perform explosion-proof painting. It is easy to operate and meets safety standards. This makes it a great choice for new robotics companies. You can automate your painting processes while maintaining flexibility by integrating cobots.

Callout The market for painting robots is expected to reach 5.8 billion dollars by 2029. This will be driven by the increasing demand for cobots. They are a great addition to modern production line because of their adaptability and cost effectiveness.

Eco-Friendly Coating Solutions

Ecological coating solutions have revolutionized industrial painting. These innovations help you maintain high standards of quality while reducing environmental impact. You can comply with regulatory requirements by adopting sustainable practices and meet consumer demand for greener goods.

Waterborne and low VOC (volatile Organic Compound) paints are now supported by modern painting robots. These coatings emit fewer harmful gases compared to traditional paints based on solvents. Waterborne paints are safer for your employees and the environment because they use water as their solvent. Low-VOC (volatile organic compounds) paints help you to create a cleaner workspace by reducing air pollution.

Tip : Using eco-friendly paints and coatings will reduce your carbon footprint, while improving your brand’s image.

Powder coatings are another environmentally-friendly option. Powder coatings do not contain solvents and therefore emit zero VOCs. This method produces a durable surface while reducing waste. The excess powder can be collected, re-used and is a sustainable and cost-effective option.

| Types of Coating | Environmental Benefit | Key Features |

|---|---|---|

| Waterborne Paints | Reduced emissions make workers safer | Water is used as a solvent |

| Low-VOC paints | Reduces air pollution | It contains fewer harmful chemicals |

| Powder Coatings | Zero VOC emissions and minimal waste | Powder can be recycled if it is not needed. |

These solutions are being adopted by automotive manufacturers. In this industry, painting robots are now used to apply eco-friendly paints precisely and in compliance with environmental standards. Integrating these technologies will allow you to achieve superior results and support sustainability.

Eco-friendly coatings are not just a fad. This is a great step towards a cleaner and greener future in your industry.

Painting robots are revolutionizing industries by automating tasks with precision and efficiency. You can rely on them to handle intricate designs, optimize paint usage, and reduce waste. Their applications span automotive, aerospace, and construction , where they enhance productivity and ensure consistent, high-quality finishes. These robots also prioritize safety and sustainability by minimizing harmful emissions and taking over hazardous tasks.

Painting robots will be a necessity by 2025 due to the advancements of AI and vision systems. Discover innovative solutions that will transform your operation, help you meet regulatory requirements, and produce superior results. Take advantage of the future of industrial paint today!