In the manufacturing industry, you’ll often find robotics automating different processes. These robotics come in handy to streamline a company’s processes and also reduce any risks of injuries. Most of the robotics that feature in such companies are robotic arms used in pick & place, assembly, and packaging among others. When it comes to these robotic arms, there are a few aspects that you should keep in mind. One of them is the robot wrist that is featured in a robotic arm. Most people don’t know much about this very crucial part of the robot arm. In this brief article, we’ll expound more on what it is and what it entails.

What is a Robot Wrist

Source: www.k-and-s.com

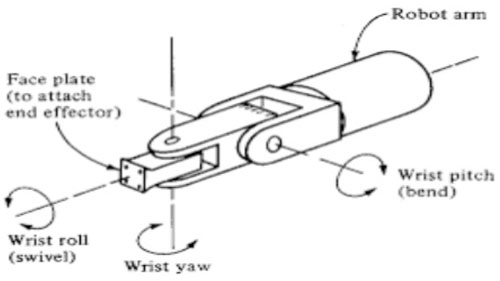

When working with a robotic arm, you have two significant components that are usually at play. This includes the body and the arm itself. On the arm, you find the robot wrist that features different joints which allows it to move in different directions. This movement allows the robot wrist to control the end effector that is attached at the end. It helps perform different tasks that the robotic arm is required to carry out. It’s all a system of different parts playing their roles to achieve a common objective. The robot wrist featured on the robotic arm comes with at least 2 to 3 compact joints that allow it to work seamlessly in different applications.

The Robot Wrist Mechanism

Source: www.brainkart.com

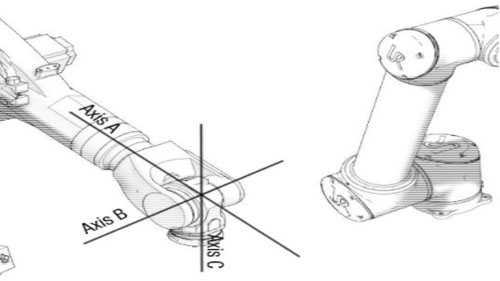

The robot wrist mechanism is a big part of the manipulator and works to orient the end effector for different applications. This mechanism consists of an arm that rotates around an axis and features joints that allow it to make different movements in various directions. The robot wrist mechanism while in use is subjected to different kinds of working environments. You find that it will be exposed to different vibrations while in use. These vibrations may negatively affect the robot wrist and its function.

The best way to ensure that your robot wrist works at its best is to study its performance carefully. Subject it to different weights on the loads being carried by the end effector to see how it performs. This will help you gauge its payload and allow you to use it in the right places to avoid bringing any damages to it. Additionally, you also need to ensure that the manipulator and the robot wrist are configured correctly. Some of the wrist configurations to keep in mind include.

Roll

This configuration is also referred to as the wrist swivel. It features the rotation of the wrist mechanism around the arm axis.

Pitch

The pitch in the wrist mechanism configuration is also referred to as the wrist bend. It features an up and down rotation of the wrist.

Yaw

With the Yaw, the wrist movement and rotation are dedicated to right and left.

Notation TRL

The notation TRL features a sliding arm that can rotate both on the vertical axis and horizontal axis.

Notation TLO

With this, the robot wrist works relative to a vertical column. This allows the wrist to move up and down or in and out depending on the tasks at hand.

Notation LOO

The notation LOO consists of three sliding joints that allow the wrist to move in different directions. Two of the three sliding joints are orthogonal. They are mainly found on rectilinear robots and X, Y, Z robots.

Importance of Wrist Configuration of Robotic Arms

Source: www.researchgate.net

It is important to ensure that the robotic arm you are using is of great quality and that it is designed accurately. One of the most important factors to consider here is the wrist configuration you’ll be working with. You need to ensure that the wrist is configured according to your specific needs. Remember the end effector will only move in the direction that the wrist takes. This goes to show that having the right configurations will ensure that the end effector can pick and place with precision.

Additionally, the right wrist configuration will help reduce any risks for injury and also damage to the robotic arm. Determine which direction the wrist should be moving for a specific task and have it modified to fit your needs. The robot wrist is an essential part of the robotic arm so be sure to have your configuration needs in check for a smoother and more seamless automation process.

Conclusion

The robot wrist is an important aspect when it comes to the use of robotic arms and manipulators for different automation tasks. It features different configurations that need to be considered before the robot wrist is put to work. This helps ensure that you are working with the best configurations designed to move the end effector in the right direction. When getting your robotic arms, consider having your robotic arm manufacturer configure it to your liking. This will allow you to start using it in your business processes with ease.