Overview

Technological developments in the ever-changing industrial sector continually result in significant gains in productivity, precision, and efficiency. Leading edge technology in this regard include laser welding robots and welding positioners. The way that industries approach welding is fundamentally changing because to these cutting-edge tools, which have unparalleled precision and adaptability. This article examines the advancements in laser welding robots and welding positioners, highlighting the features, applications, and exceptional capabilities of two products: the QJR6-2000H Welding Robot and the EVS-DWP-P-200/500/1000 Positioner.

An Introduction to Robotics in Laser Welding

Because they provide a degree of control and accuracy that is superior to that of traditional welding procedures, laser welding robots are widely used in modern manufacturing. These robots use laser beams to mix materials, resulting in very accurate and dependable welding. Laser welding robots provide a number of benefits. They significantly boost production efficiency by reducing the amount of time required for each task by finishing complex welds swiftly and effectively. Additionally, they improve worker safety by lowering the necessity of human intervention in risky circumstances.

One of the most obvious characteristics of laser welding robots is their precision. Because of the laser beam’s focused intensity, welding can be done with extreme precision, which is essential in industries where accuracy is valued, including aerospace and auto manufacturing. Additionally, due to their extreme versatility, laser welding robots may be used to weld a wide range of materials, including carbon steel, copper, aluminum, and stainless steel. Their versatility makes them useful in a variety of industrial environments.

Comprehensive Product Overview – QJR6-2000H Welding Robot

One of the best examples of how laser welding technology has advanced is the QJR6-2000H Welding Robot. With a 6KG payload and a 2014mm reaching distance, this six-axis robot is ideal for a range of welding operations. Its design has a hollow wrist U-shaped structure to increase joint support stiffness and provide more flexibility, as well as a gear gaps adjustment structure to improve joint accuracy. In addition, the QJR6-2000H has an anti-shake optimization to lower end clearance and increase operating rigidity, as well as a unique noise reduction construction for quieter operation.

All of these characteristics combine to create an extremely powerful welding robot that is dependable and precise. Because of its versatility in handling different materials, the QJR6-2000H is a useful tool in any production environment. The device’s repeat positioning precision of ±0.08mm guarantees uniform and superior welds, which are crucial for upholding strict quality requirements during manufacturing.

Welding Positioner Innovations

Another essential part of the contemporary welding process are welding positioners. Workpieces can be held and manipulated by these tools, enabling ideal welding location. The precision and quality of the welds are improved by welding positioners, which give exact control over the workpiece’s angle and orientation. For intricate or large-scale projects where manual placement would be difficult and time-consuming, this feature is especially crucial.

The potential of sophisticated welding positioners to increase workflow efficiency is their main advantage. These devices lessen the time and effort needed to set up and modify workpieces by automating the positioning process. Lower labor costs and quicker manufacturing times are the results of this efficiency. Furthermore, welding positioners improve safety and ergonomics by minimizing the need for workers to handle bulky or oddly shaped materials.

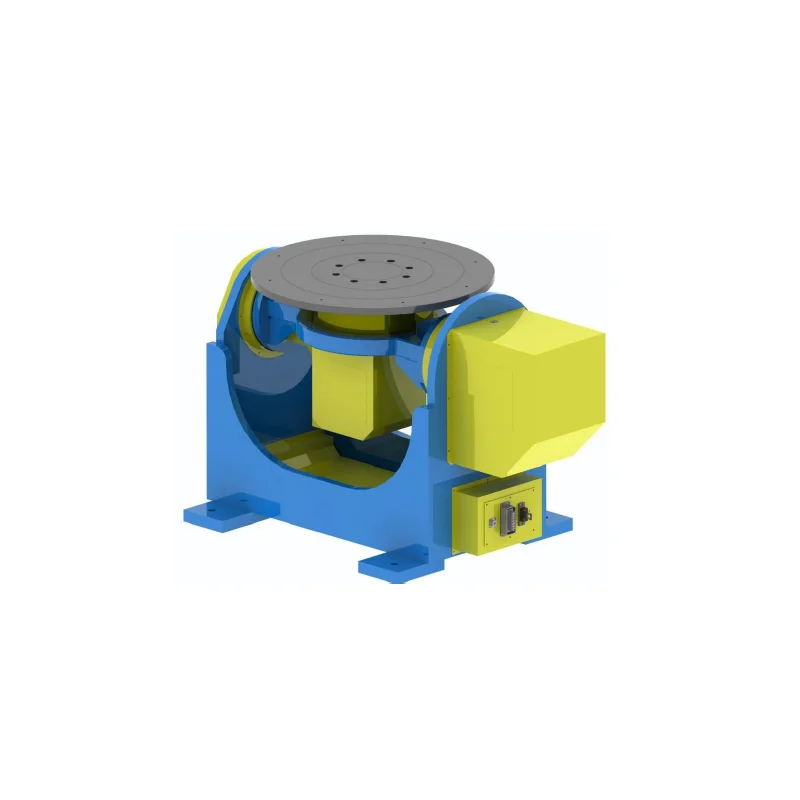

Comprehensive Product Details – EVS-DWP-P-200/500/1000 Positioning Device

The newest developments in welding positioner technology are best shown by the EVS-DWP-P-200/500/1000 Positioner. With its versatility in load capacities, this double-axis servo positioner finds use in a multitude of applications. Its sturdy welding frame, gyration platform, and AC servo motor with an exact reducer are all part of its construction, which guarantees steady and precise placement. In order to increase the positioner’s longevity and security, its design also includes a conductive system and protective cover.

The EVS-DWP-P-200/500/1000 Positioner’s excellent repeat positioning accuracy, which varies depending on the model, ranges from ±0.10mm to ±0.20mm, is one of its most notable attributes. It takes this degree of accuracy to produce consistently excellent welds. The gyration speeds of the positioner on both axes have been tuned to guarantee seamless and effective operation, so augmenting production even more.

Combining Robots for Laser Welding with Positioners

The combination of welding positioners with laser welding robots is a major advancement in production technology. These instruments have a synergistic impact that improves total production capacity when combined. While welding positioners guarantee the workpieces are positioned and stabilized optimally, laser welding robots deliver the speed and precision required for high-quality welds.

Construction, aerospace, and the automotive industries have already started to reap the rewards of this convergence. For instance, in the automotive sector, accurate welding of car body components is made possible by laser welding robots and welding positioners, leading to the creation of stronger and more dependable automobiles. In the aerospace industry, the combination guarantees performance and safety by enabling precise welding of crucial aircraft parts.

The advantages of combining welding positioners and laser welding robots are obvious. Because of their increased flexibility, manufacturers can now take on a greater variety of projects with different levels of complexity. Improved accuracy and productivity lower the possibility of mistakes and rework, which saves money and produces goods of a higher caliber. Moreover, the enhanced overall production is a result of the optimized processes and decreased downtime.

In summary

In conclusion, the industrial sector is changing as a result of developments in laser welding robots and welding positioners. These technologies allow producers to attain greater quality standards and shorter production timelines because they provide never-before-seen levels of accuracy, efficiency, and flexibility. The QJR6-2000H Welding Robot and the EVS-DWP-P-200/500/1000 Positioner are two excellent illustrations of the inventiveness with which these instruments may be employed.

Future possibilities for laser welding robots and welding positioners are bright as long as technology keeps developing. Their skills should continue to advance, making them even more crucial to the production process. These technologies’ continued advancement will surely result in new uses and possibilities, enhancing their status as indispensable instruments in contemporary industry.