A silent rhythmic dance of gears and motors provides the vitality that propels industries forward. This article provides an in-depth analysis of gear motors and motorgear boxes, which are critical components within the vast machinery of contemporary industrialization.

Introduction

In the grand timeline of human achievement, the milestones of mechanical innovation shine with a special significance. Among these, the development of motorgear boxes and gear motors represents a leap forward in our ability to harness the raw power of motion. Central to everything from the gentle whir of a printer to the earth-shaking movement of cranes at a busy port, these technologies have quietly shaped the efficiency and functionality of countless applications.

This investigation centers on two exceptional products that exemplify the highest level of motion technology: the versatile HSBW Series Gearmotors and the durable G Series Industrial Gearbox. Although their contributions may be overlooked in the grand scheme of things, their influence is palpable throughout numerous sectors, as they push the limits of what is feasible in the fields of mechanical engineering and automation.

Understanding Motorgear Boxes

The Essence of Motorgear Boxes

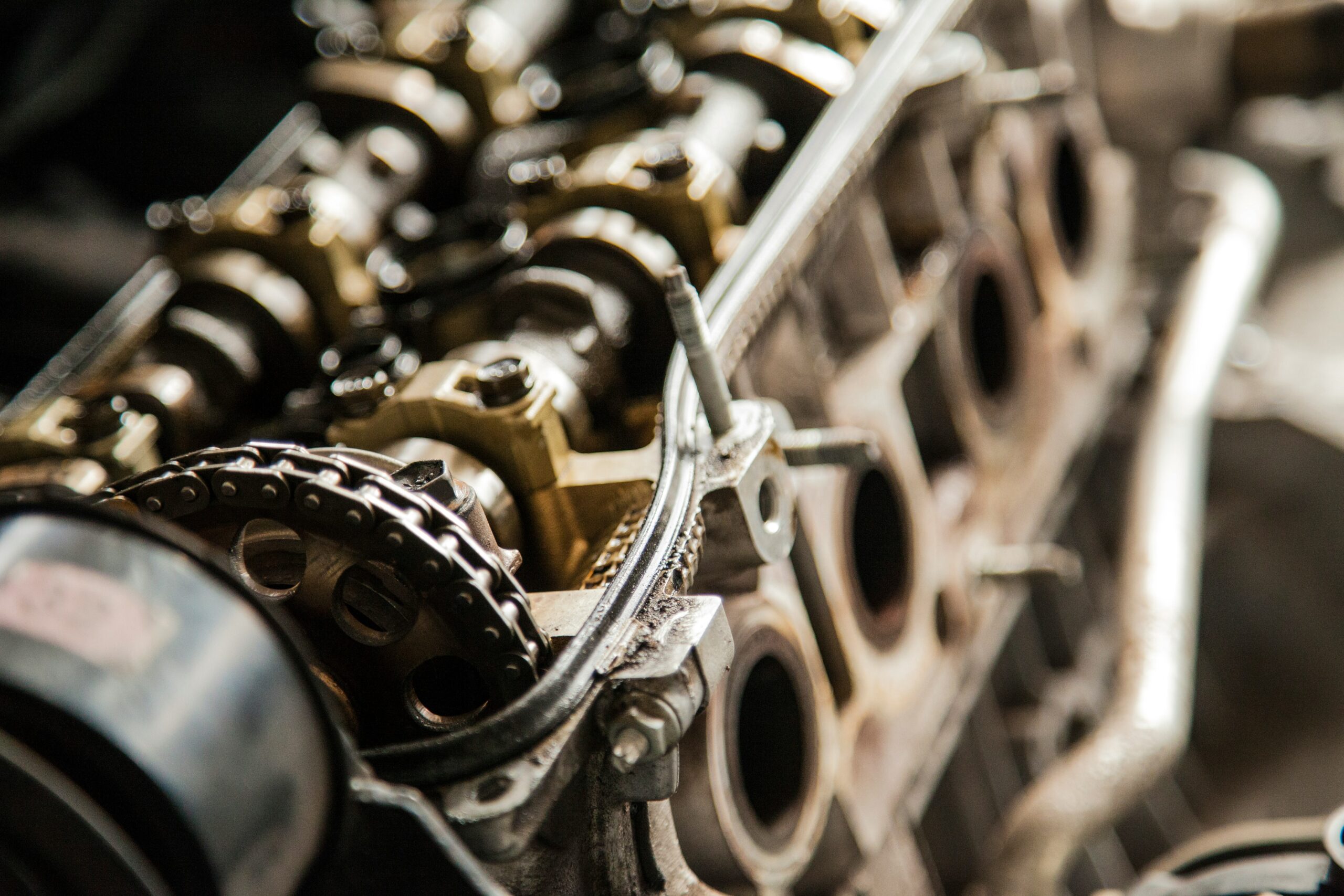

A motorgear box, at its essence, serves as an embodiment of the discipline of precision engineering. This intricate component integrates a gearbox and motor with the purpose of controlling the velocity, force, and trajectory of machinery. The magic of the motorgear box lies in its capacity to transform the high-speed, low-torque output of a motor into a force that is lower-speed and higher-torque. This conversion is crucial for an innumerable number of machines that influence our everyday existence, ranging from the most basic kitchen appliances to the most intricate production lines.

The Historical Tapestry of Motion Technology

The lineage of motorgear boxes is as old as the history of machinery itself. From the rudimentary systems of the industrial revolution to the sophisticated units of today, motorgear boxes have undergone a metamorphosis. Each era of innovation brought forth enhancements in materials, design, and performance, culminating in today’s advanced systems that mesh seamlessly with the digital age.

Motorgear Boxes: The Drivers of Efficiency

In the relentless pursuit of efficiency, motorgear boxes have emerged as champions. Their ability to minimize energy waste while maximizing output has made them indispensable in efforts to achieve sustainable production models. In factories around the world, these motorgear boxes are the unsung heroes, ensuring that machines perform at their best with the least environmental footprint.

The Technological Advances in Motorgear Boxes

Showcasing the most recent advancements in computer-aided design, material science, and electronics, contemporary motorgear boxes are engineering marvels. Reflecting the technological advancements that have permeated their development to an extreme degree, they are more intelligent, versatile, and compact. Motorgear boxes offer previously unheard-of levels of feedback and control as they become more integrated with the systems they power with each new generation.

The Role of Motorgear Boxes in Performance Enhancement

Motorgear boxes are not just components; they are the linchpin in a multitude of devices that demand precise motion control. By optimizing the torque and speed, motorgear boxes ensure that machines can perform tasks that range from the delicately precise to the robustly forceful. Whether it’s in robotics, where precision is paramount, or in heavy-duty construction equipment that requires immense force, motorgear boxes are the crucial elements that facilitate performance enhancement.

The Integration of Smart Technology in Motorgear Boxes

As a result of the emergence of Industry 4.0 and the Internet of Things (IoT), motorgear boxes have begun to integrate intelligent and connected technologies. Presently, motorgear boxes are equipped with sensors capable of real-time condition monitoring, maintenance demand prediction, and autonomous operation adjustment to guarantee ongoing optimization. This degree of integration signifies a paradigm shift, portending a future in which motorgear boxes are an integral component of both the mechanical and digital infrastructures.

The G Series Industrial Gearbox – Unveiling the Specifications

An Overview of G Series Industrial Gearbox

Upon examining the G Series Industrial Gearbox, one is presented with a remarkable demonstration of contemporary engineering excellence. Designed to endure the arduous conditions prevalent in industrial settings, these motorgear boxes boast an exceptional degree of adaptability in addition to their robust construction. They function as the structural support for machinery that requires consistent power and unwavering performance.

The Technical Excellence of G Series

Peering into the technical parameters of the G Series Industrial Gearbox, we find a range that caters to a variety of needs – from a ratio spectrum of 1.25 to 450, to output torque capabilities stretching from 2.9 to 900 Kilo-Newton meters. This wide array of specifications ensures that for nearly any application, there’s a G Series gearbox fit for the task.

Applications and Industry Impact

Recognizing the requirements of a wide variety of applications, the G Series Industrial Gearbox is a chameleon in the realm of motion technology. Prominent sectors such as cement, chemical, paper, mining, and even the food industry have adopted these gearboxes due to their impressive specifications. For this straightforward reason, the G Series is consistently prepared to provide dependable and accurate motion control.

Versatility Meets Durability

The G Series Industrial Gearbox is not just about raw power; it’s about delivering that power consistently over time, under varying conditions. This resilience is what makes them ideal for applications that range from transportation to mixing, slewing, hoisting, and pumping. Whether it’s the constant load of a conveyor belt or the intermittent stress of a crane lift, the G Series remains steadfast.

Gear Motors – A Compact Solution

The Compact Power of Gear Motors

The marvel of gear motors lies in their compact size paired with their capability to deliver high torque. These are complete motive packages, combining electrical motors with gear reduction systems to form a single, integrated unit. This efficient amalgamation not only saves space but also simplifies design by eliminating the need for separate components.

Gear Motors versus Traditional Motors

In contrast to conventional motor systems, gear motors present a more streamlined methodology. Gear motors step in to provide optimal performance in applications where space is limited and efficiency cannot be compromised. Their integration reduces the number of required components, which not only decreases the likelihood of mechanical failure but also diminishes assembly expenses and time.

Advancements in Gear Motor Technology

The domain of gear motors is witnessing a multitude of developments, such as the application of novel materials to enhance durability and the integration of sophisticated electronics to optimize control and energy efficiency. Modern gear motors are undergoing engineering optimization to seamlessly integrate with sophisticated control systems, with the aim of attaining an unparalleled level of precision.

HSBW Series Gearmotors – A Technological Leap

Introducing HSBW Series Gearmotors

When the HSBW Series Gearmotors are examined, one discovers a product line that serves as a prime illustration of the most recent progressions in gear motor technology. Designed to fulfill the most stringent industrial criteria, these gear motors provide a blend of durability, accuracy, and power.

Technical Specifications of HSBW Series Gearmotors

Diving into the specifics, the HSBW Series boasts an impressive range of ratios from 1.39 to 27,001, power options extending from 0.12 to 160 kilowatts, and output torque capacities that scale from 1.4 to 23,200 Newton meters. Such extensive ranges signify the adaptability of these gear motors to a multitude of tasks and conditions.

Power Across Applications

The HSBW Series Gearmotors are not just about versatility; they are about delivering consistent power across a plethora of applications. Be it in packaging, transportation, hoisting, mixing, or pumping, these gear motors are designed to enhance the efficiency and reliability of operations.

Impact on Industries

The introduction of the HSBW Series into the market has made a noticeable impact on several industries, including steel, power, port, cement, and even tobacco. By providing a reliable source of motion, they have enabled these sectors to achieve new levels of productivity and efficiency.

Applications and Industries Transformed

Pioneering Applications

The prowess of motorgear boxes and gear motors extends across a broad spectrum of applications. In packaging, their precision allows for the delicate handling and efficient processing of goods, while in transportation, they provide the necessary torque for vehicle propulsion and load management. Similarly, in hoisting and mixing applications, they offer the controlled strength and endurance needed for lifting heavy loads and blending materials seamlessly.

Transformation Across Industries

These technologies are not just part of industrial operations; they are often at the heart of innovation within these sectors. In the steel industry, for example, the robustness of motorgear boxes ensures the relentless movement of materials in high-temperature environments. In power generation, gear motors contribute to the fine control of mechanisms critical to energy production. Ports worldwide rely on these components for the smooth operation of cranes and loading equipment, cement plants for their grinding mills, and the chemical sector for their precise manufacturing processes.

Case Studies: Motorgear Boxes and Gear Motors at Work

Case studies from various industries demonstrate the significant impact of motorgear boxes and gear motors. For instance, in a leading port, the introduction of HSBW Series Gearmotors reduced downtime and maintenance costs, enhancing operational efficiency. In a food processing plant, G Series Industrial Gearboxes were pivotal in scaling up production while maintaining the delicate handling required for quality assurance.

Future Trends in Motorgear Box and Gear Motor Technology

Predicting Advancements

In the field of motorgear boxes and gear motors, new developments are soon to be made. It is expected that forthcoming developments in the field of materials science will yield systems characterized by enhanced durability and efficiency. It is likely that the incorporation of machine learning and artificial intelligence will enable geargear boxes and gear motors to execute predictive maintenance and real-time optimization. This will almost certainly result in enhanced functionality and increased longevity.

Sustainability and Energy Efficiency

Innovations in gear motors and motorgear boxes will persistently be influenced by the sustainability trend. Manufacturers are increasingly prioritizing the development of energy-efficient designs in response to the declining carbon emissions associated with industrial processes. Components will be developed to operate in conjunction with those that are environmentally sustainable and renewable energy sources, prior to their official introduction.

New Frontiers of Application

Prospects for the utilization of gear motors and motorgear boxes are significantly broadening. The escalating adoption of automation and robotics across diverse sectors such as healthcare, space exploration, and agriculture will inevitably necessitate compact, robust, and accurate motion control solutions. It is anticipated that these technologies will assume an even more substantial role in promoting innovation across diverse industries in the coming years.

Conclusion

Recapping the Motion Technology Marvels

As we have navigated through the intricacies of motorgear boxes and gear motors, it’s clear that these components are more than mere cogs in the industrial machine—they are the very drivers of progress. The G Series Industrial Gearbox and the HSBW Series Gearmotors stand as prime examples of this, embodying the cutting-edge of technology in their field. Through their robust design, adaptable functionality, and precise control, they demonstrate the incredible strides we have made in motion technology.

The G Series and HSBW Series: Pillars of Industry

The technical specifications and diverse applications of the G Series and HSBW Series speak to their central role in modern industry. They showcase the possibilities when ingenuity meets practical needs—where every gear and every motor is fine-tuned to meet the high demands of today’s industrial processes. From the steel mills that shape our cities to the transportation networks that connect them, these motorgear boxes and gear motors are integral to our continuous march towards efficiency and innovation.

Embracing the Future of Industrial Motion

In light of imminent breakthroughs and innovations, it is critical to acknowledge the significance of wholeheartedly adopting these technological developments. The integration of motorgear boxes and gear motors with the digital realm, their contribution to sustainability, and their role in pushing the limits of what is possible are all crucial factors that will determine their future.

The progression of innovation is continuous, and upon gazing towards the future, one discerns a terrain in which the HSBW Series Gearmotors and the G Series Industrial Gearbox persistently transform. Not only will they fulfill the requirements of the future, but they will also propel the development of that future—a realm in which motion technology propels humanity forward at an unprecedented rate and with unparalleled efficiency.