Introduction

An explosion of technological advancements ushered in the twenty-first century, transforming the industrial landscape as well as our daily lives. In this industrial revolution, robust automation solutions such as polishing robots and robot tracks are leading the way. These developments hold the potential to increase manufacturing processes’ previously unheard-of productivity and efficiency. The QJR20-1600 robotic arm stands out among these cutting-edge technologies due to its remarkable payload capacity and long reach. Being the first nationally certified explosion-proof spraying robot available, it creates opportunities for sectors that require accuracy and security. The EVS Robot track is a state-of-the-art platform that promises to further enhance robot capabilities, and it complements these innovations. When combined, these technologies are paving the way for an infinitely promising future.

The Revolution of Polishing Robots

Defining Polishing Robots

As the name implies, polishing robots are automated systems made to precisely and consistently manage the complex process of polishing. Through the use of robotic arms such as the QJR20-1600, industries are witnessing a notable increase in throughput and quality.

Features of the QJR20-1600 Robotic Arm

In the world of polishing robots, the QJR20-1600 robotic arm is the pinnacle of innovation. The 20kg payload and 1668mm arm span give polishing tasks a new level of dynamic. Its explosion-proof construction guarantees safe operation in areas with combustible materials, which is revolutionary for industries like aerospace engineering and the automobile manufacturing sector.

Explosion-Proof Polishing Robots: A Safety Breakthrough

Safety in volatile environments is non-negotiable. The QJR20-1600 robotic arm’s explosion-proof capability not only ensures compliance with rigorous safety standards but also provides peace of mind. This feature alone sets a new benchmark for polishing robots in hazardous conditions.

QJR20-1600: A Paradigm Shift in Robotics

Technical Specifications Unveiled

A technological marvel, the QJR20-1600 is not just another polishing robot on the market. With six axes for complex movements, a maximum arm span of 1668mm for extended reach, and repeat positioning accuracy of ±0.05mm, among other technical specs, it offers unparalleled precision.

Speed and Accuracy: The Industrial Ballet

When it comes to polishing robots, speed and accuracy are akin to a well-rehearsed ballet – each movement must be both graceful and exact. The QJR20-1600 excels here, with its axes capable of swift movements up to 355º/s, ensuring that no time is wasted between each precise polishing stroke.

Versatility Across Applications

The QJR20-1600 shines across a spectrum of applications beyond just polishing. Its versatility makes it suitable for palletizing, handling, loading and unloading, laser cutting, and spraying – making it a multifaceted workhorse in any industrial setting.

Next-Gen Robot Tracks: The Path to Enhanced Automation

The Role of Robot Tracks

Robot tracks are the silent partners to polishing robots, extending their range and versatility. They act as the ground upon which robots traverse, enabling them to cover larger workspaces and carry out tasks with increased flexibility.

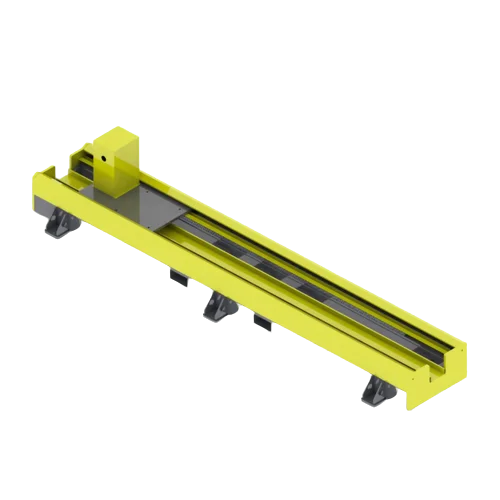

Introducing the EVS Robot Track

The EVS Robot track exemplifies the next generation of robot tracks. Customizable in both load and length, it is adaptable to various industrial needs. It serves as a foundation for robots, allowing for fluid and precise movements across extended areas, a vital attribute for tasks requiring the utmost accuracy.

Customization Meets Industry Needs

In an era where customization is king, the EVS Robot track‘s ability to be tailored to specific requirements is invaluable. Whether it’s the length of the track or the rated load, this adaptability ensures that the robot tracks can support polishing robots in any context they are deployed.

EVS Robot Track: Engineering Precision and Versatility

Technical Parameters Explored

Delving deeper into the technical parameters of the EVS Robot track reveals its engineered precision. With a repeat positioning accuracy of ±0.10mm for payloads under 1000kg and ±0.15mm for heavier loads, it stands as a testament to the precision engineering that goes into robot tracks.

Applications of Robot Tracks in Automation

Robot tracks are not just limited to supporting polishing robots. Their utility spans across welding, cutting, handling, machining, painting, and gluing. The EVS Robot track, with its robust build and precise movement, is an asset in all these applications, underlining its versatility.

Semi-Enclosed Protection for Longevity

One of the standout features of the EVS Robot track is its semi-enclosed protection design. This thoughtful addition ensures that the robot tracks are shielded from environmental factors, thus enhancing their longevity and reliability.

Case Study – Qianjiang’s Leap Towards Automation with QJR20-1600

Teaching-Free Technology and Digital Production

In a striking example of automation’s potential, Qianjiang implemented the QJR20-1600 robotic arm to modernize the production of stainless steel cookware. Leveraging teaching-free technology, the robot facilitates rapid line changes and enables a fully unmanned digital production process, a significant milestone for the industry.

Energy Efficiency in Robotic Operations

The energy-efficient design of the QJR20-1600, complemented by its servo driver and frequency converter, allows for a 10% reduction in power consumption during standby modes. This not only reduces operational costs but also aligns with global sustainability goals.

SCADA System Integration for Performance Monitoring

The integration of a self-developed SCADA system offers Qianjiang remote monitoring capabilities for their polishing robots. This allows for real-time tracking of performance rates, speed, maintenance schedules, and even remote software updates, ensuring optimal performance and minimal downtime.

The Synergy of Polishing Robots and Robot Tracks

Combined Use in an Integrated System

The pairing of QJR20-1600 polishing robots with EVS Robot tracks creates a symphony of efficiency and precision. This synergy allows for seamless operations over extended workspaces, maximizing productivity and minimizing the potential for human error.

Benefits of Robotic Synergy

The collaboration between polishing robots and robot tracks extends beyond mere convenience. It introduces a level of automation that can dramatically transform the speed, accuracy, and consistency of industrial processes such as polishing, ensuring superior quality and throughput.

Shaping the Future of Automated Polishing

Modern polishing robots such as the QJR20-1600, combined with sturdy robot tracks such as the EVS system, pave the way for the automation of polishing and other fine industrial operations in the future. These technologies will surely open up new doors for manufacturers all over the world as they develop.

Conclusion

In conclusion, the advancements in polishing robots and robot tracks exemplified by the QJR20-1600 and EVS Robot track are more than mere technological achievements; they are the harbingers of a new industrial era. The case study of Qianjiang’s successful integration of these technologies underscores their transformative potential. The importance of these innovations grows as industries all over the world strive for safety, accuracy, and efficiency. They open the door to a future where productivity will soar and where the limits of what is conceivable will be continuously expanded.