Introduction

Technological innovations have proved to be particularly influential within the dynamic manufacturing landscape. One such innovation is robotic arc welding, where the integration of advanced welding robots and efficient welding turntables has revolutionized several industrial sectors, thereby enhancing the productivity, accuracy, and dependability of manufacturing processes.

Emergence of Advanced Welding Robots

Robots that conduct difficult welding jobs with exceptional precision have evolved from simple, programmable machines to extremely sophisticated gadgets. The history of welding robots in the manufacturing sector is one of ongoing invention and evolution. A prime example of this evolution is the 6KG Payload 1.4M Reaching Distance 6 Axis Welding Robot QJR6-1400H. This model boasts multiterm exclusive patents, showcasing its unique capabilities in the market. With features like joint gear grip adjustment for fine control, a hollow joint support structure for improved rigidity and flexibility, and a specialized noise reduction structure, this welding robot exemplifies the advanced engineering in modern robotic systems. Its technical prowess is further highlighted by its impressive repeat positioning accuracy of ±0.08mm and an armspan of 1456mm, making it an ideal choice for working with diverse materials such as carbon steel, stainless steel, aluminum, and copper.

Innovation in Welding Robot Design

Further advancing the field of robotic welding is the 6KG Payload 2014mm Reaching Distance 6 Axis Welding Robot QJR6-2000H. This model introduces an innovative gear gaps adjustment structure to improve joint accuracy, alongside a hollow structure with a wrist U-shaped design that enhances joint support stiffness, offering greater flexibility. The robot’s antishake optimization reduces end clearance and improves operating stiffness, minimizing control error. The noise reduction structure, a patented feature, ensures a quieter operating environment. This welding robot also boasts an impressive repeat positioning accuracy of ±0.08mm and an extended armspan of 2014mm, accommodating larger workpieces with ease. Its technical parameters, including a broad motion range and high allowable torque, make it a versatile and efficient tool in any welding application.

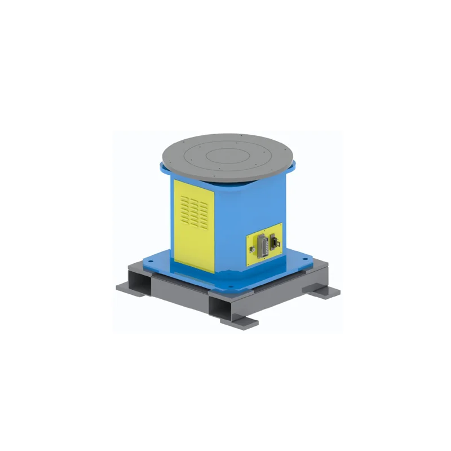

Role of Welding Turntables in Robotic Welding

Welding turntables are a crucial component of any robot’s toolkit for making the most of the welding process. Welding turntables and robotic systems together not only increases productivity but also guarantees consistency and uniformity in the quality of the welded product by providing a stable, controllable surface for the workpiece to rotate on. This allows robots to access a wide range of angles and positions without having to realign themselves.

Case Study 1: Motorcycle Production Line

An exemplary implementation of welding robots can be seen in a project involving 21 units of QJRH4-1A welding robots and 6 units of QJRB20-1 handling robots in a motorcycle production line. The project’s success was further highlighted by the robots’ adherence to strict quality standards, having passed the CE test and ISO 9001: 2015; this commitment to quality is supported by a $10 million investment in high-standard testing machines, ensuring the welding robots‘ precision and dependability. These welding robots significantly increased productivity and reduced labor costs, illustrating the transformative impact of robotic welding in the automotive sector.

Case Study 2: Fitness Equipment Welding Project

Another compelling case study is the use of QJRH4-1 robots and single-axis positioners in a fitness equipment welding project. The QJRH4-1 robot, with its 4kg load capacity, repetitive positioning accuracy of ±0.03mm, and an armspan of 1410.5mm, exemplifies the advanced capabilities of modern welding robots. Synchronized movement of the welding robot and turntable resulted in smoother, more stable, and tighter welding seams; the exceptional quality and convenience of use of these welding robots demonstrate the potential of robotic welding in a range of manufacturing situations.

Future Trends in Robotic Arc Welding

Robotic arc welding looks like it will keep getting better. Improved quality, flexibility, and efficiency of manufacturing processes will ensure robotic welding’s position as an essential part of industrial production. New developments in welding robots and turntables should lead to even more inventive methods of satisfying the diverse and constantly changing demands of various industry sectors.

Conclusion

From the production of automobiles to fitness equipment, modern welding robots and turntables have undoubtedly changed the face of manufacturing and ushered in a new era of productivity and accuracy in production. As these technologies continue to advance, the industrial sector will inevitably benefit more from them, representing the beginning of a time when automated welding will be synonymous with superior manufacturing. Find out more about welding robots and welding turnables at EVS Int.