Overview

Precision and efficiency have been greatly increased in industrial manufacturing as a result of the advancements in welding technology. Integrating cutting-edge technology is essential for upholding high production standards in today’s cutthroat industry. This study examines the advantages of combining robotic welding systems with welding turntables, emphasizing the synergistic effects that improve overall performance.

An Overview of Robotic Welding

Due to their ability to automate the welding process, maintain uniformity, and minimize human error, welding robots have had a profound impact on industry. In many industrial applications, these robots are vital because they can perform repeated welding tasks precisely and consistently.

Qualities of the QJR6-1400H

When it comes to welding robots, the 6KG Payload 1.4M Reaching Distance 6 Axis Welding robot QJR6-1400H is one model that stands out. Because of its multiterm exclusive patents, this robot is unique and provides more affordable solutions than comparable items. Its hollow joint support construction offers more stiffness and flexibility, and its joint gear gip adjustment enables for fine control and fast dynamic reaction. Furthermore, the structure designed to reduce noise guarantees a very low running sound, which makes it appropriate for a variety of industrial settings. The QJR6-1400H has an armspan of 1456mm with a repeat positioning accuracy of ±0.08mm, making it suitable for handling materials including copper, aluminum, stainless steel, and carbon steel.

Comprehending Turntable Welding

Turntables for welding are vital equipment that improves the accuracy and productivity of welding processes. These tools offer a steady surface on which workpieces may revolve, enabling consistent welding from various viewpoints. Regardless of the intricacy of the workpiece, welding turntables guarantee dependably high-quality welds.

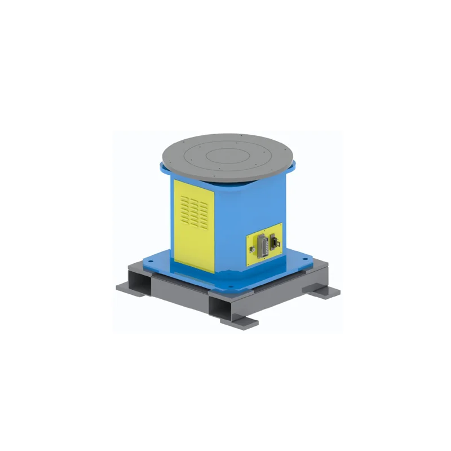

EVS-SWP-ZW-500/800/1200 Features

The EVS-SWP-ZW-500/800/1200 Single Axis Welding Positioner is a perfect illustration of a welding turntable that works well. Fixing base, RV accurate reducer, gyration main spindle case, tail case, welding gyration frame, AC servo motor, conductive system, and protective cover are all included with this positioner. High gyration stability, precise alignment, and extended longevity are guaranteed by its design. This welding turntable has a rated load capacity of 500 kg to 1200 kg and a repeat positioning accuracy of ±0.10 mm to ±0.15 mm, making it appropriate for a wide range of industrial applications.

The precision and accuracy of welding processes are greatly improved by the combination of welding robots and welding turntables. Although welding robots are meant to do high-precision operations, welding turntables‘ reliable rotating control greatly enhances their potential. This combination minimizes the possibility of errors and rework by ensuring that welds are applied consistently.

Enhanced Efficiency of Workflow

Workflow efficiency may be significantly increased by combining welding robots with welding turntables. Welding robots can operate continuously because welding turntables enable continuous rotation of workpieces. This smooth functioning speeds up the welding process overall and decreases downtime. Manufacturers are therefore able to increase production rates without sacrificing constant quality.

Useful Applications and Advantages for Industry Use Cases

There are several sectors that benefit from the combination of welding turntables and welding robots. This combination, for example, is utilized in the automobile industry to weld components with great accuracy and repeatability, guaranteeing the structural integrity of cars. For the aerospace sector to successfully weld vital components that must resist harsh environments, precision control offered by welding robots and turntables is essential. These cutting-edge welding techniques’ increased precision and efficiency also aid other industries, like construction and heavy machinery.

ROI and Cost-Effectiveness

Using welding robots in conjunction with welding turntables has significant long-term cost benefits. A positive return on investment (ROI) is achieved despite a potentially large original expenditure thanks to increases in productivity, less material waste, and lower labor expenses. This combination is an affordable option for industrial welding operations as it may eventually balance the initial costs due to less rework and increased productivity.

In summary

To summarize, the incorporation of welding turntables into robotic welding systems has a multitude of advantages, such as improved accuracy, heightened productivity, and significant financial savings. When paired with efficient welding turntables like the EVS-SWP-ZW-500/800/1200, welding robots like the QJR6-1400H provide a reliable solution for a range of industrial applications. The use of these systems is anticipated to grow in popularity as technology develops, leading to more advancements in quality standards and production procedures.

This combination ensures that producers may reach faster production rates while keeping constant quality thanks to its smooth operation and better management. The heavy machinery, aerospace, and automobile sectors have already recognized the advantages, and it is anticipated that additional industries will follow suit as they adopt these innovative welding techniques. The benefits of welding robots and welding turntables, which ensure both productivity and precision in their operations, may help manufacturers keep an edge in a competitive market.