Introduction

Welding technology is essential to industrial production in today’s societal development since it is a necessary component of industrial manufacturing. The welding industry has benefited immensely from the advancement of modern technology, which has led to the creation of high-tech equipment like laser welding robots and welding positioners. Prominent firms in the sector, like EVS, have consistently enhanced the accuracy of their robot-assisted welding processes while also boosting overall productivity and production efficiency. This article delves into the benefits of integrating EVS welding positioners and laser welding robots into manufacturing operations.

Understand welding locator

Welders can use welding positioners to fix and rotate workpieces, keeping them in a stable and comfortable position throughout the entire welding process. These instruments are necessary for producing high-quality welds, especially in complex and substantial projects. The platform dual axis servo locator (EVS-DWP-P) and the single axis tail welding locator (EVS-SWP-ZW) are the two most famous models of EVS in this field.

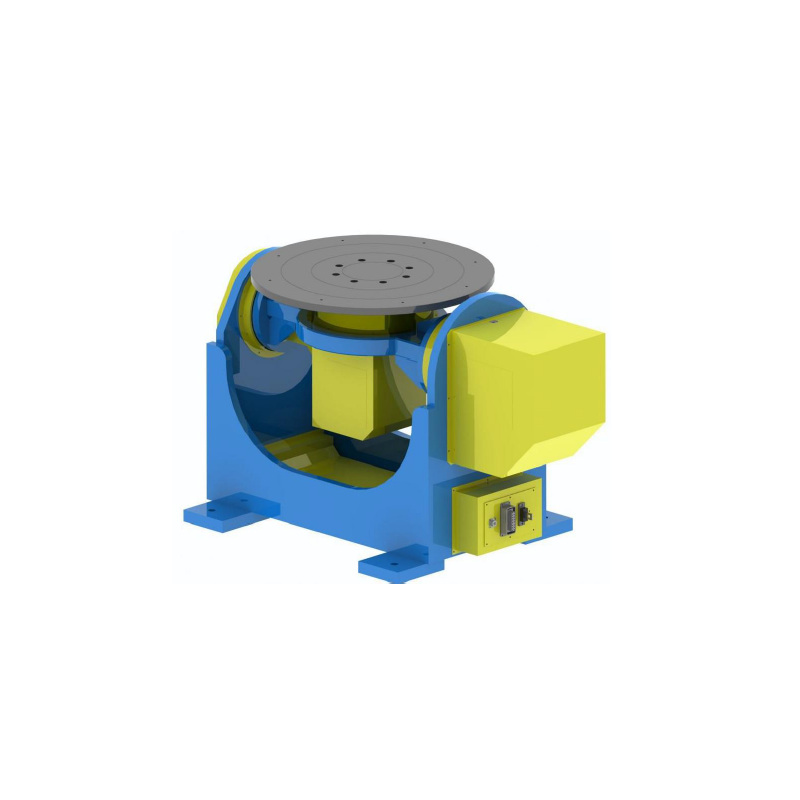

EVS-SWP-ZW Single Shaft Head Tailstock Welding Positioner

The EVS-SWP-ZW series comes in three different weight models -500 kg, 800 kg, and 1200 kg. For heavy-duty welding operations, these single axis locators can provide reliable support and precise control.

Important features:

In terms of load capacity, these locators can accommodate versions of 500 kg, 800 kg, and 1200 kg, and can handle various workpieces. In precision control, high-quality welds depend on precise and smooth placement, which is achieved by complex control systems. In terms of durability, these locators are made of high-quality materials designed to withstand harsh environments in industrial applications.

Advantages:

EVS-SWP-ZW helps welders maintain their ideal position by fixing and rotating workpieces, thereby reducing fatigue and increasing productivity. Consistent alignment ensures uniform welds, thereby reducing errors and rework. Suitable for a range of welding tasks, such as complex assembly and large-scale projects.

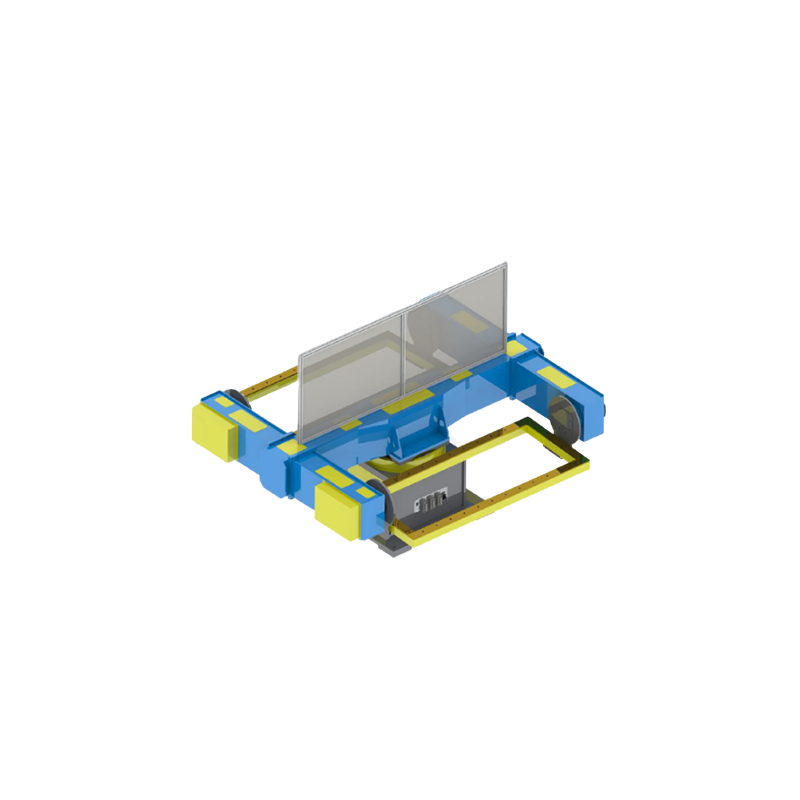

Platform EVS-DWP-P Dual axis Servo Positioner

The EVS-DWP-P series offers dual axis servo positioners, with variants capable of handling weights of 200 kilograms, 500 kilograms, and 1000 kilograms. With their complex servo control, these locators provide accurate and adaptable placement.

Important features:

By using dual axis control, the workpiece can be positioned along two axes, providing more versatility. In the servo control system, precision servo motors ensure high precision and seamless operation. Provide stability and precise alignment during welding on a sturdy platform.

Advantages:

Dual axis design enables complex placement to accommodate various welding operations. The servo control system provides precise motion, which is crucial for complex welding processes. Even in harsh industrial environments, a sturdy structure can ensure long-term reliability.

Investigations into robots for laser welding

Laser welding robots offer unmatched speed and accuracy and are the pinnacle of welding technology. Because these robots use laser beams to make high-quality welds with low distortion, they are extremely ideal for applications that need high strength and precision.

The following are the primary benefits of laser welding robots:

Robots that use laser welding are able to create extremely exact welds, which is essential for sectors like aerospace and electronics. These robots’ quick running speeds significantly increase output rate. Laser welding creates a lower heat-affected zone (HAZ) than traditional welding processes, which lowers the likelihood of material deformation. Since they may be used to weld a variety of materials, including metals and alloys, they have a wide range of uses.

The benefits of integrating EVS welding positioners with laser welding robots

Boost precision and standard

The weld seam quality is consistently high when the laser welding robot’s accuracy is paired with the EVS welding locator’s ability to precisely locate the weld. Both tools’ state-of-the-art control systems offer accurate welding and placement, reducing mistakes and guaranteeing consistency.

Boost productivity

Productivity is significantly increased by the automation and welding locator offered by laser welding robots. The welding robot can operate constantly since the finder makes sure the workpiece is always in the ideal welding position, reducing downtime and boosting productivity.

Boost safety

Welding processes are robotically automated, which reduces the need for human intervention in potentially dangerous scenarios. The locator further increases safety by lowering the possibility of accidents by firmly fastening the workpiece.

Adaptability and broadness

EVS welding positioners and laser welding robots can be adapted for simple welding to complex components. Because of its versatility, producers may get the most out of their investment by employing the same tools for different jobs.

Economy of cost

Modern welding equipment may have a high initial cost, but over time, costs will be drastically decreased. Increasing productivity, decreasing rework, and improving welding quality lead to lower operating costs and more profitability.

Application and Case Studies

The automotive industry: The assembly of car bodies and frames is completed in this industry using a combination of laser welding robots and welding positioners. The precision of laser welding ensures a sturdy and lightweight weld seam, and the locator provides you with the necessary degrees of freedom to use various components.

Aerospace industry: Laser welding accuracy and low heat affected zone are crucial for aerospace applications. Positioners enable precise alignment of components, protecting the integrity and safety of critical structures.

Heavy Machinery: The powerful features of EVS welding positioners and laser welding robots enable them to easily handle large and heavy components in the construction of heavy machinery, achieving high-quality welding and high productivity output.

In short

Future welding operations will depend on the integration of cutting-edge technologies like welding positioners and laser welding robots. EVS is leading this change by offering state-of-the-art equipment to increase welding operations’ precision, effectiveness, and safety. Employing laser welding robots and equipment like EVS-DWP-P and EVS-SWP-ZW welding positioners allows businesses to increase output, streamline operations, and stay competitive in the ever-changing industrial market.

For more detailed information about these products, please visit the following website:

Platform dual axis servo locator EVS-DWP-P single shaft head tail welding locator EVS-SWP-ZW

With EVS’s most advanced laser welding robots and welding positioners, you can embrace the future of welding operations and improve your production processes.