Introduction

Welding positioners are crucial equipment in the complex field of fabrication and assembly, greatly improving the calibre and efficiency of welding operations. Because of their accuracy and consistency, they are essential in many industries for producing high-quality welds. This article presents a comprehensive examination of two advanced products produced by EVS, namely the Single Axis Welding Positioner and the Platform Two Axis Servo Positioner. These items serve as prime examples of the latest advancements in the domain of welding positioner technology.

A Comprehension of Welding Positioners

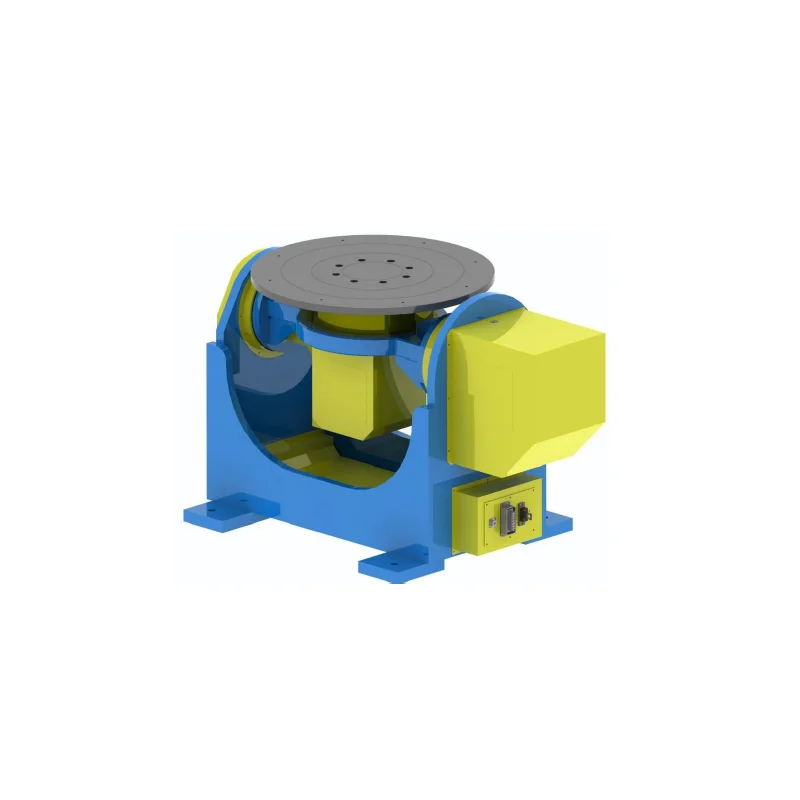

The welding process is facilitated by the manipulation and positioning of a workpiece in an ideal manner, which is the function of specialised apparatus called welding positioners. The precision and uniformity of the welded material, which are essential components of a high-quality welding process, are guaranteed by their implementation. Exemplary in the field of welding automation, the Single Axis Welding Positioner EVS-SWP-ZW and the Platform Two Axis Servo Positioner EVS-DWP-P are outfitted with features such as repeat positioning accuracy and rated gyration speed.

Welding Positioner Varieties

A multitude of welding positioners exist, each specifically designed to accommodate distinct welding needs. As is the case with the EVS-SWP-ZW, the single-axis design is appropriate for straightforward duties in which one-dimensional motion is adequate. Conversely, the Platform Two Axis Servo Positioner EVS-DWP-P’s versatility is augmented by its two-axis capability, which fits welding applications involving more complex procedures exceptionally well. Central to these mechanisms is the welding turntable, an indispensable constituent that facilitates the rotation and positioning of the workpiece during the welding process.

Considerations Crucial to the Selection of a Welding Positioner

When choosing the appropriate welding positioner, there are a number of crucial factors to consider. Primarily, load capacity, positioning precision, and gyration velocity are elements that warrant investigation. Illustratively, the EVS-DWP-P and EVS-SWP-ZW variants possess unique load capacities that render them appropriate for a diverse range of workpiece dimensions: 500kg to 1200kg for the former, and 200kg to 1000kg for the latter. Additionally, it is imperative to consider the repetition positioning accuracies and rated gyration rates of the welding positioner to ensure that it meets the exact requirements of its intended application.

Advantages of High-Quality Welding Positioners

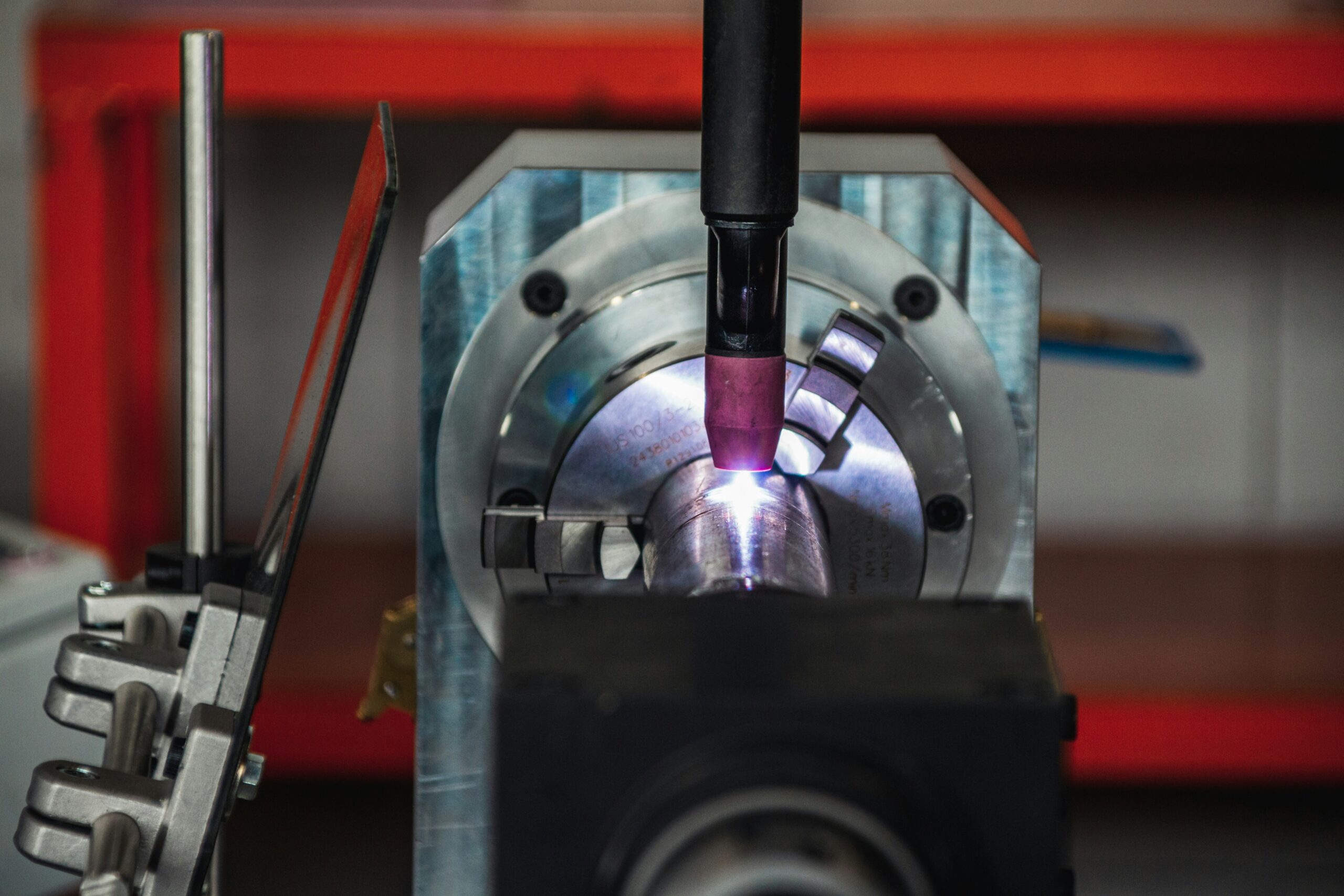

Utilising welding positioners of superior quality, such as those provided by EVS, has numerous advantages. The superior electrical conductivity of these positioners, which is achieved through the use of brass conductive material, safeguards other components. The models are endowed with stress-relieved components that augment their precision, steadfastness, and longevity. Furthermore, the integration of servo motors and reducers of superior quality ensures a minimal rate of malfunction and exceptional gyration stability, thereby making a substantial contribution to the welding procedure’s accuracy and effectiveness.

Practical Implementations of Welding Positioners

Particularly in sector where robotic welding systems are implemented, welding positioners have a wide range of applications. Due to their adaptability in accommodating and positioning components of diverse sizes and shapes, EVS welding positioners play a crucial role in industries such as heavy equipment manufacturing, automotive, and aerospace. The aforementioned uses demonstrate the adaptability of welding positioners, which can manipulate both small, straightforward components and sizable, intricate assemblies.

Determining Which Welding Positioner Suffies Your Requirements

The process of choosing a suitable welding positioner for particular duties necessitates meticulous evaluation of technical specifications, the operational setting, and the characteristics of the welding operation. Ensuring that the capabilities of the welding positioner align precisely with the requirements of the production line is of utmost importance. Aspects such as the cargo capacity, welding turntable type, and required precision are crucial in influencing this decision-making procedure.

Prospects for the Future of Welding Positioner Technology

Ongoing progress and novel developments characterise the future of welding positioner technology. An emerging trend seems to be the development of welding positioners that exhibit enhanced precision, efficiency, and versatility. It is expected that the aforementioned developments will aid in the progression of welding procedures through the continued enhancement of welding positioners‘ functionalities and the broadening of their industrial applications.

To conclude,

In conclusion, for welding operations to be precise and productive, it is vital to select the proper positioner. When selecting a welding positioner, it is critical to take into account a number of factors, including load capacity, positioning accuracy, and the style of welding turntable, as emphasised in this article. Such models as the EVS-DWP-P and EVS-SWP-ZW serve as prime examples of the progress made in this domain by providing comprehensive welding solutions. With the ongoing advancement of technology, welding positioners will inevitably gain greater capability to enhance the quality and efficacy of welds. Consequently, they have become an essential instrument in contemporary fabrication and assembly procedures. Visit EVS Int for more information.