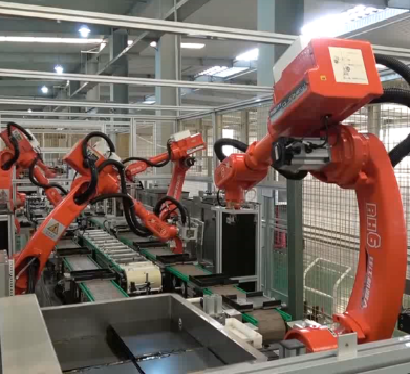

An Overview of Six axis robots and Manufacturing Robotics

The correct six axis robots are essential for maximizing efficiency and accuracy in the rapidly developing field of robotics in manufacturing. A variety of six axis robots from EVS are available to satisfy various manufacturing requirements. Three models—QJR20-1600, QJR10-2, and QJR210-1—are compared in this article. You may choose the model that best meets your manufacturing needs by looking at the characteristics and advantages of these six axis robots.

QJR20-1600 Six-Axis Robot: Juggling Accuracy and Power

Applications like assembly, material handling, and welding that call for a blend of speed and accuracy are ideally suited for the six-axis QJR20-1600 robot. Because of its sophisticated control systems, which guarantee seamless operation, manufacturers aiming to increase efficiency can rely on it. Additionally small in size, this six-axis robot makes it simple to integrate into current manufacturing lines.

Extra Details:

20 kg of payload makes it ideal for medium-duty jobs.

Reach: 1671 mm, offering a flexible range of use.

Control systems: cutting-edge technology for accurate motion.

Applications: Perfect for material handling, welding, and assembling.

Design: Small and simple to include into manufacturing processes.

QJR10-2 Six-Axis Robot: Accuracy for Difficult Assignments

For applications demanding great precision and flexibility in robotics in manufacturing, the QJR10-2 six-axis robot is created. This robot’s extended 2001mm reach and 10kg payload make it ideal for applications where accuracy is critical. When handling tiny components carefully is required for delicate tasks like electronics assembly, the QJR10-2 performs exceptionally well. With its sophisticated motion control, this six-axis robot can do jobs with accuracy and ease. Because of its longer reach, it can reach wider workspaces, which makes it a useful tool for producers who need precision and flexibility.

Extra Details:

Payload: 10 kg, perfect for tasks requiring accuracy.

Reach: 2001 mm; ideal for rooms with more space.

Control systems: sophisticated motion control for careful tasks.

Applications: Ideal for fine-tuning and assembling circuits.

Design: Enhanced for accuracy and versatility in challenging jobs.

The powerful QJR210-1 six-axis robot is ideal for heavy-duty applications

Heavy-duty robotics in manufacturing are the focus of the QJR210-1 six-axis robot. This robot, with its amazing 2688mm reach and 210kg payload, is built for large-scale activities. Applications requiring the handling of heavy materials, such large-scale assembly and the automobile industry, are well suited for the QJR210-1. Even with the highest load, stability and dependability are guaranteed by its sturdy design. This six-axis robot’s sophisticated control systems enable precision movement in spite of its robust capabilities, making it an invaluable tool in any industrial environment.

Extra Details:

210 kg of payload that is intended for heavy-duty use.

2688mm of reach makes it ideal for large-scale tasks.

Control Systems: Accurate control over movement even with large loads.

Applications: Perfect for large-scale assembly and car manufacture.

Design: Stable and robust for optimal dependability in industrial environments.

Tips for Selecting the Best Six-Axis Robot for Your Manufacturing Requirements

The QJR20-1600 is a great option if your concentration is on medium-duty activities that call for a balance of power and precision. In situations where long reach and excellent precision are required, the QJR10-2 is clearly the best choice. But the QJR210-1 is the finest option if your operations involve heavy-duty jobs that call for strong handling capabilities. For various facets of robotics in manufacturing, each of these six axis robots has certain benefits to offer.

Six axis robots’ Place in Contemporary Manufacturing

These robots increase output and save operational costs since they are designed to do challenging tasks with little help from humans. The use of six axis robots into manufacturing processes allows organizations to retain high levels of precision even in large-scale production environments. You can optimize your manufacturing processes and keep your competitive edge in a market that is changing rapidly by choosing the best six-axis robot for your specific needs.

Conclusion: Choosing the Best Six-Axis Robot for Your Needs

In conclusion, EVS offers a range of six axis robots designed to meet the diverse needs of robotics in manufacturing. Whether what you need is balanced power from the QJR20-1600, accuracy from the QJR10-2, or the heavy-duty capabilities of the QJR210-1, EVS has a solution to match your needs. With knowledge of the features and benefits of each model, you can make an educated decision that enhances your production processes and grows your business. To witness the production of the future in action, get the perfect six-axis robot right away.

To learn more about these items, go to the following website:

You may enhance your manufacturing procedures and keep your competitive edge in the robotics in manufacturing sector with the aid of QJR10-2, QJR20-1600, and QJR210-1 EVS six axis robots.