An Overview of Welding turntables and Robots

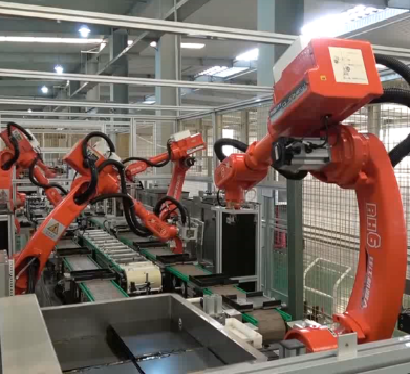

Accuracy and efficiency are achieved in current manufacturing by using welding robots and welding turntables. High-end EVS welding robots, such as the QJR6-1400H and QJR6-2000H, may greatly increase operational productivity when paired with welding turntables. This essay examines how these two cutting-edge welding robots compare and considers how industrial welding operations may be completely transformed by their integration with welding turntables.

The QJR6-1400H Welding Robot’s features

A highly adaptable six-axis robotic arm made specifically for precision welding jobs is the QJR6-1400H welding robot. With a 1.4-meter reach and a 6 kilogram payload capacity, it’s perfect for complex welding tasks. The sophisticated control systems on this robot guarantee precise and fluid motions, improving the caliber of the welds. Its small size makes it simple to incorporate into current production lines, offering efficiency and flexibility in a range of industrial environments. Because of its long-term dependability and robust design, the QJR6-1400H is a crucial component of contemporary industry.

Extra Details:

6 kg of payload makes it ideal for mild to medium duty.

Reach: 1.4 meters, offering a wide field of operation.

Control Systems: Precise and seamless functioning are guaranteed by cutting-edge technology.

Construction: For durability, premium materials were used in the construction.

Applications: Ideal for accurate welding jobs, packing, and assembly.

Advantages of QJR6-1400H Utilizing Welding turntables

Combining the QJR6-1400H welding robot with a welding turntable has several advantages. The workpieces may revolve smoothly thanks to the welding turntable, and the welding robot’s steadiness and control guarantee excellent welds. This combination increases productivity and efficiency by lowering the need for manual intervention. Because of its advanced characteristics, the QJR6-1400H welding robot is a solid choice for businesses aiming to enhance their welding procedures. By combining with welding turntables, this welding robot can produce precise welds in challenging places.

Extra Advantages:

Precision: Provides superior control and high-quality welding.

Productivity: Increases efficiency by reducing physical work.

Stability: Gives control necessary for precise job completion.

Performance: Reliable and consistent functioning.

Efficiency: Improves weld quality and overall operating efficiency.

The QJR6-2000H Welding Robot’s features

For longer welding jobs needing a wider working range, the QJR6-2000H welding robot is made. With a reach of 2014 mm and a payload capacity of 6 kg, this welding robot is appropriate for intricate and substantial welding tasks. Because of its sophisticated control systems and ability to operate smoothly and precisely, the QJR6-2000H is a great option for sectors where precision and flexibility are essential. Additionally, this welding robot works well with welding turntables, facilitating smooth workpiece movement and enabling the robot to precisely conduct welds from a variety of angles.

Extra Details:

Payload: 6 kg; ideal for more demanding jobs.

Reach: 2014mm, offering a longer range of use.

Control systems: Advanced technology for accurate functioning.

Construction: Long-term dependability is ensured by using sturdy materials.

Applications: Perfect for heavy-duty material handling, packing, and assembly jobs.

Advantages of QJR6-2000H for Turntables Used for Welding

For large-scale industrial applications, the QJR6-2000H welding robot in conjunction with a welding turntable offers substantial benefits. Because of its longer reach, this welding robot can efficiently handle larger workpieces. The welding robot can access challenging angles with the help of the welding turntable, assuring accuracy in intricate welding jobs. By eliminating the need for human adjustments, the QJR6-2000H’s integration with welding turntables improves welding operations’ precision and productivity. The QJR6-2000H welding robot is a very adaptable instrument in the industry thanks to this combination.

Extra Advantages:

Load Capacity: Easily manages more demanding jobs.

Precision: Provides reliable, excellent performance.

Efficiency: Lowers the need for physical labor while boosting output.

Control: Guarantees precise and seamless operations.

Versatility: Perfect for a range of demanding robotics and logistics applications.

Using EVS Welding turntables and Robots to Improve Welding Operations

The precision and operating efficiency of welding turntables are greatly increased when EVS welding robots are integrated with them. These welding robots provide high-quality results by precisely manipulating and placing components. Turntables that are welded require less human adjustments, which boosts output and lowers mistakes. These welding robots‘ sophisticated characteristics guarantee steady, reliable performance, which is crucial for streamlining the welding process. Industries may improve job accuracy and operating efficiency by utilizing EVS welding turntables and welding robots.

Extra Improvements:

Accuracy: Meticulous manipulation for superior results.

Productivity: Boosts effectiveness while requiring fewer manual changes.

Consistency: Dependable and seamless functioning.

Control: Guarantees precise material management.

Quality: Boosts task accuracy and operational efficiency.

In summary: Using EVS Welding turntables and Robots to Increase Production

To sum up, EVS welding robots are crucial equipment for streamlining processes in industrial environments. The cutting-edge characteristics of the QJR6-2000H and QJR6-1400H welding robots improve accuracy, output, and efficiency. These welding robots provide high-quality results by offering stability and control when paired with welding turntables. Businesses that use EVS welding robots and welding turntables may significantly increase task accuracy and operating efficiency. To improve your welding processes and maintain your competitive edge in the industrial environment, invest in EVS welding robots right now.

Visit the following product pages for further information in-depth on these products:

EVS welding robots and welding turntables may improve your operations right now.