Feel free to contact us on industrial robots and we will gladly answer any of your questions.

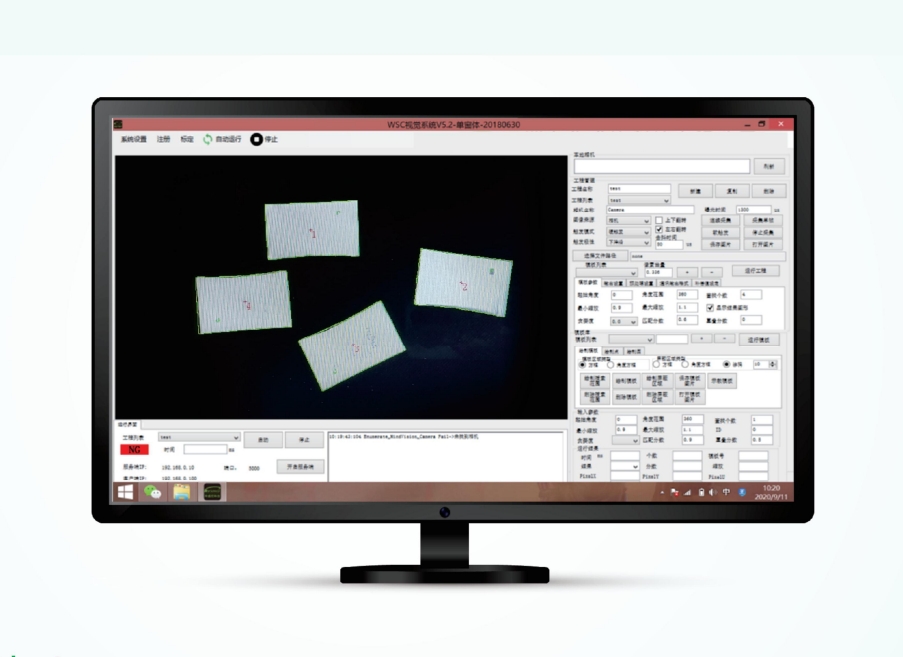

Fast matching:

Fast search for a match between the target and the advance setting modelwithin the camera’s field of view.

Fast positioning:

When the target’s matching score, overlap score is greater than or equal tothe template matching score and greed score, the target search is completedand the centre coordinates, angle and template model are quickly calculatedand the result is passed to the server or client.

Precise positioning:

With geometric template positioning, measurement, identification, defects,.logic operations, image pre-processing, etc.

High compatibility:

Supports most of the image acquisition devices on the market, with a widerange of applications.

Human-computer interaction:

Easy to use, good compatibility with Huashengkong parallel robot system,tried and tested in mobile assembly line operations.

Data protection:

With multiple user levels of authority to set the operation, to prevent datatampering.

| Model | EVSPG-10/20/30A | |

| Visual Software | The Software Supports The Operating System | Win7/10 32&64-bit system |

| Compatibility | Support Most Of The Image Acquisition Equipment on The Market | |

| Development Language | C++/Halcon | |

| Development Environment | QT | |

| Data Protection | Multiple user level permission settings | |

| Function | Image preprocessing,shape feature matching,circle fitting, point following.multi-template matching,image calibration and so on | |

| Camera | Camera Type | Black And white/Color |

| Models | MV-GE130GM-T/MV-GE502GC-T-CL-90 | |

| Sensors | 1/3″CMOS | |

| Shutter Type | Global Shutter | |

| Resolution@Frame Rate | 1280*960@60.6FPS/2592X2048@22FPS | |

| Effective Pixels | 1.22 Million/5.02 Million | |

| Acquisition Mode | Continuity/softtrigger/hard trigger | |

| Visual Software | GigEVisionV1.2、GenIcam | |

| Lens Interface | C Interface | |

| Data Interface | Rj45 Gigabit Ethernet interface,Down Compatible With 100M Network Standard | |

| Function | Support any size Roi custom resolution,contrast and gamma adjustment,saturation adjustment,white balance correction,black level correction,custom dead-point coordinates correction,ISP image processing acceleration,3D noise reduction,custom LUT table,frame rate adjustment,custom camera name | |

| Camera | Models | M0814-MP2/M1214-MP2/M1614-MP2 |

| Focal Length | 8mm/12mm/16mm | |

| Maximum Aperture Ratio | 1:1.4 | |

| Maximum Picture Size | 8.8mm*6.6mm(Ф1lmm) | |

| Interface | C Interface | |

| Scope of work | Aperture:F1.4-F16C Focus:0.1m-inf./0.15m-inf./0.3m-Inf | |

| Control | Aperture:manual Focus:manual | |

| Operating Temperature | -10~50°C | |

| Light Source | Type | LED Strip/Strip Light Source |

| Industrial Control Computer | Models | IPC-610H |

| Processor | i5-3570 | |

| Network Card | 2 Gigabit Ports | |

| Compatible With Motherboard Type | ATX Standard | |

Mainly applied to the pharmaceutical industry granule class punch class and other products cartoning. Fast speed,.good precision and easy to use. Optional following and vision system is available to meet flexible production requirements.

Easy to operate: different materials can be adjusted to the movements to suit the packaging requirements through the software.

Good Integration: it can be easily integrated into mechanical equipment and production lines.Powerful function: Material Counting, stacking and sorting can be performed.

High Intelligence: intelligent vision for automatic positioning and tracking,flexible gripping and automatic deflection correction.

Simple maintenance:simplify robot structure,reduce maintenance difficulty and system cost.

Pillow sorter includes conveying assembly line, robot frame, vision system, parallel robot, etc. The overall structure is precise and compact,occupying little space and saving site resources. It adopts flexible design to adapt to different products, with fast line change and simple debugging. It can greatly improve production efficiency and reduce production cost.

Fast speed: 100*n/min.

Fast line change: suitable for various types of products, the product can achieve 15 minutes to change the line

Fast tuning: easy to operate, easy to debug product replacement operation

Modular: modular parallel connection, fast installation,

Intelligent: intelligent vision automatic positioning tracking, flexible gripping, automatic correction of deflection.

| Work efficiency | 85-110 packages/min |

| Efficiency improvement rate | 40% |

| Existing Labor | 2 people |

| Replacement of Labor | 1 people |

| Cost reduction rate | 40% |

Provide glass bottle hot end annealing transfer line, Cold end sorting transfer line and other link process alternative solutions. Effectively solve the problem of recruitment difficulties and reduce Labor costs.Customize special gripper fixture according to the actual situation of customer’s site process to improve work efficiency.

Features:

(1)Multi-species identification: simultaneous identification and handling of three to five different types of bottles.

(2)Strong durability: high temperature resistance and long service life.

(3) Strong flexibility: flexible gripping, no damage to bottles.

| Work efficiency | ≤60个/分钟 pcs/min |

| Efficiency improvement rate | 35% |

| Existing Labor | 6 people |

| Replacement of Labor | 3 people |

| Cost reduction rate | 30% |

Mainly applied to the arrangement and boxing of soft bags and boxed materials. The cartoning machine adopts top cartoning method, and the robot grabs and cartons single or multiple pieces, with high flexibility, fast speed, good precision and easy to use. Optional following and vision system is available to meet flexible production requirements.

Features:

Easy to operate: Different materials can be adjusted to the movements to suit the packaging requirements through the software.

Good Integration: it can be easily integrated into mechanical equipment and production lines.

Powerful function: material counting, stacking and sorting can be performed.

High Intelligence: intelligent vision for automatic positioning and tracking,flexible gripping and automatic deflection correction.

Simple Maintenance:simplify robot structure, reduce maintenance difficulty and system cost.

| Work efficiency | 60-65 packages/min (single machine) |

| Efficiency improvement rate | 20% |

| Existing Labor | 6 people |

| Replacement of Labor | 5 people |

| Cost reduction rate | 40% |

The incoming material from the front section equipment is accurately identified by the vision inspection system, and the upper tray is used with the DELTA robot to complete the sorting and traying of various accessories. Improve production efficiency.reduce Labor and management costs. Flexible design, fast line change and simple debugging.

Flexibility: stable and superior speed and flexible gripping

Fast transfer: simple operation, easy debugging and fast product line change.

Intelligent: intelligent vision automatic positioning and tracking,automatic correction of deviation.

| Work efficiency | 60-120 times/min |

| Efficiency improvement rate | 20%-40% |

| Existing Labor | 3 people |

| Replacement of Labor | 2 people |

| Cost reduction rate | 30% |

EVS Robotics is an industrial robot supplier providing automation solutions and support to our customers. Our products are used in industrial automation such as welding, painting, handling, palletizing, bending and polishing. And after years of development, our core technology has been widely used in different industries like Automotive, Metal Industry, Food & Beverage, Medical & Pharmaceutical and more.

Copyright ©EVS TECH CO., LTD All rights reserved.All materials not authorized may not be redirected or for other usages.