Introduction

Gear motors are critical components that are required for an extensive range of industrial applications in the intricate domain of mechanical engineering. When used in combination with the appropriate gearbox, these motors possess the capacity to greatly improve performance and efficiency. Proficiency in selecting the appropriate gear motor gearbox is critical across numerous industries. The objective of this article is to assist the reader in making a well-informed decision by offering a thorough study of gear motors and gearboxes. This accomplishment is made possible by the wide array of items employed, such as gear motors from the H, S, B, and W series.

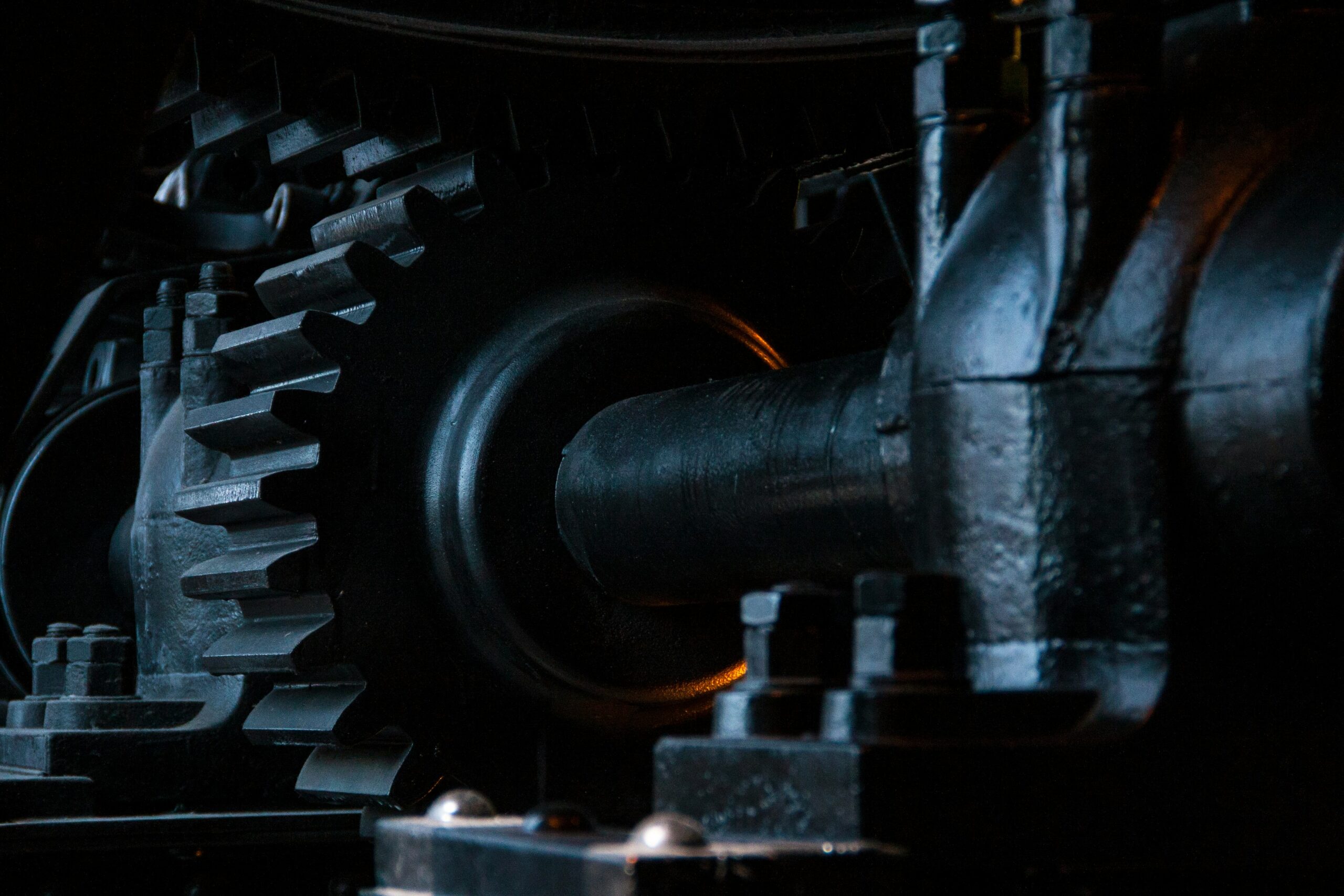

Comprehending Gearboxes and Gear Motors

Gear motors consist of an electric motor that is connected to a transmission at their most fundamental level. The gearbox is accountable for modulating the output torque and speed of the motor. By virtue of this specific capability, the transmission can be modified with such accuracy as to satisfy the requirements of a given application. Over the duration of our inquiry, we conduct a comprehensive examination of multiple models, which comprise the B Series Helical-Worm Geared Motor, the H Series Helical Geared Motor, and the S Series Parallel Shaft-Helical Geared Motor. Every individual motor is produced in contrast to a unique set of specifications that are sector-specific to its respective industry.

Different Gearbox Types

A plethora of transmission configurations exist, each possessing a distinct array of attributes and practical uses. Helical gearboxes are typically utilised in applications that demand high speeds due to their exceptional efficiency and silent operation. The Parallel Shaft-Helical gearbox is an optimal choice for spaces with restricted elevation owing to its compact design. Combining strength and durability, the Helical-Bevel transmission from the B Series is ideal for applications requiring heavy-duty performance. In conclusion, the W Series Helical-Worm gearbox can produce a great deal of torque at a low speed, making it suitable for applications requiring substantial cargo movement.

Selecting the Correct Gearbox for Your Gear Motors

The process of selecting the right gearbox for your gear motor is rather complex. The method includes considering the operational load, the necessary pace, and the environmental circumstances. A conveyor system might work best with a H Series Helical gearbox because of its efficiency and speed, while a heavy-duty lifting operation might require a B Series Helical-Bevel gearbox because of its dependability.

Advantages of Gearboxes and Gear Motors That Are Optimally Matched

The utilisation of a suitable gearbox in conjunction with a gear motor yields numerous benefits. It prolongs the machinery’s lifespan and improves all aspects of its performance, including longevity and efficiency. Combining gear motors with gearboxes like the HSBW Series can enable them to operate at their best. This illustrates how useful gear motors are in a range of industrial settings.

Uses for Gear Motors with Various Gearboxes

Every kind of gearbox has a specific use in a range of industrial settings. For instance, the S Series performs exceptionally well in hoisting and mixing tasks, whereas the H Series is frequently utilised in packaging and transportation. The B Series is frequently observed in heavy industrial environments such as the production of steel and cement, whereas the W Series is frequently observed in the processing of chemicals and tobacco. These uses demonstrate the adaptability and significance of gear motors across a wide range of industries.

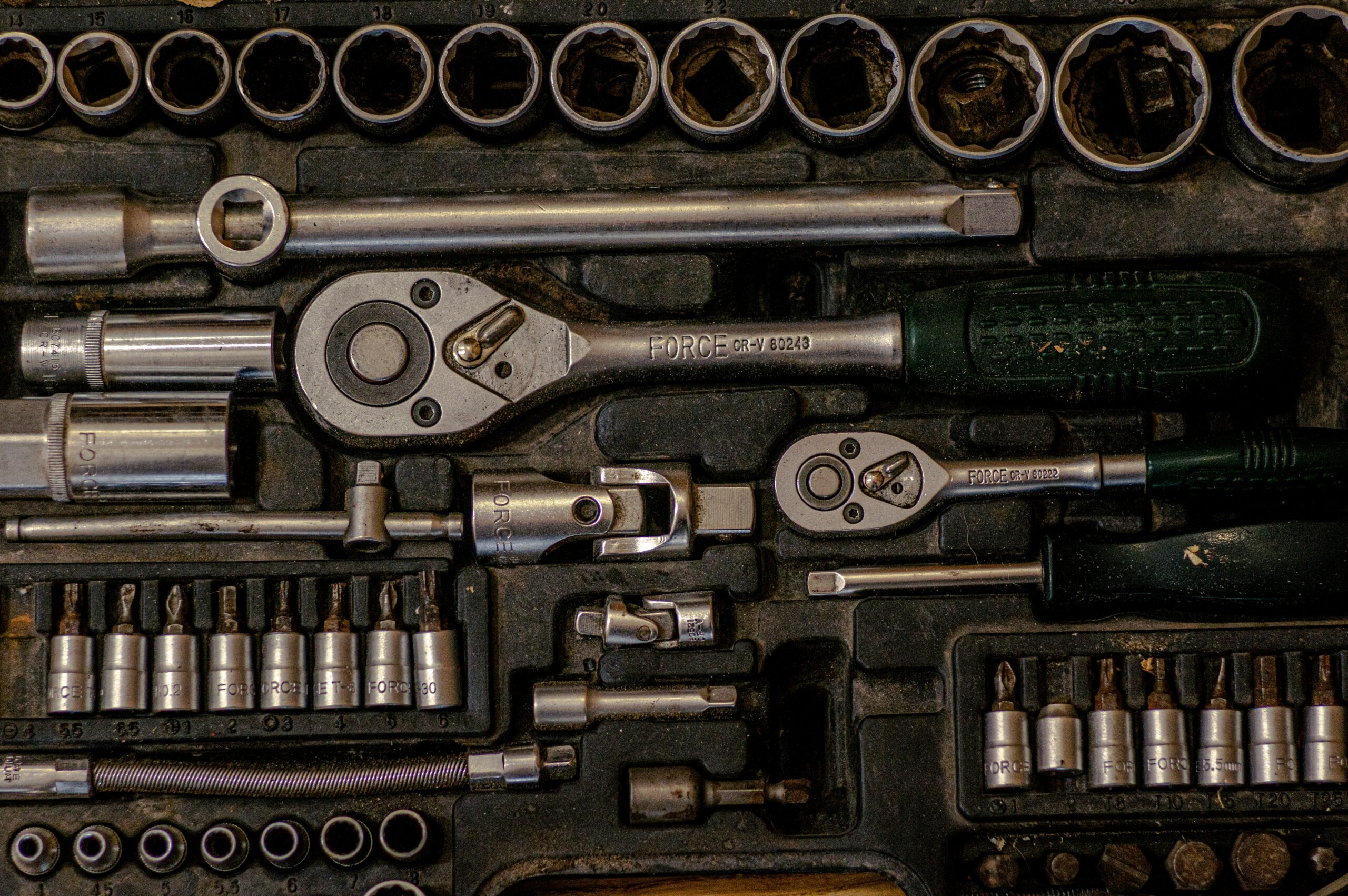

Things to Think About When Selecting a Gearbox

A number of considerations must be made prior to choosing a transmission for a gear motor. Crucial factors to bear in mind encompass the restrictions imposed on decibel levels, the operational environment of the system, and the obligations associated with its maintenance. The selection technique also takes into account several technical factors, such as output torque, power capacity, and gear ratio. Ensuring the gearbox and motor are compatible is crucial for achieving optimal economy and performance.

Upcoming Developments in Gearbox and Gearmotor Technology

Gearboxes and gear motors are always evolving due to ongoing technical advancements. Subsequent versions of these elements are expected to exhibit more adaptability and efficiency, as shown by evolving patterns. Advancements in materials research and design are expected to result in transmissions that possess enhanced durability, reduced weight, and improved energy efficiency. These advances are expected to improve the capabilities of gear motors in many industries.

Conclusion

The careful consideration and choice of an optimal transmission for a gear motor is a critical undertaking that can significantly influence the overall functionality and efficiency of industrial machinery. The primary aims of this article were to furnish readers with an extensive comprehension of the abundant assortment of gearboxes and gear motors that are presently accessible, as well as to offer direction on how to choose the gearbox or gear motor that most closely aligns with one’s particular operational requirements. Undoubtedly, technological advancement will result in an expanded marketplace offering gearboxes and gear motors for sale. As a consequence, there will be heightened potential for the enhancement of industrial applications. Visit EVS Int for more information.