Source: Ebay

When SCARA robots were first invented, they were intended to solely be assembly robots hence the name Selective Compliance Assembly Robot. However, they have since advanced into many more functions and designs. As such, they are now referred to as Selective Compliance Articulated Robots.

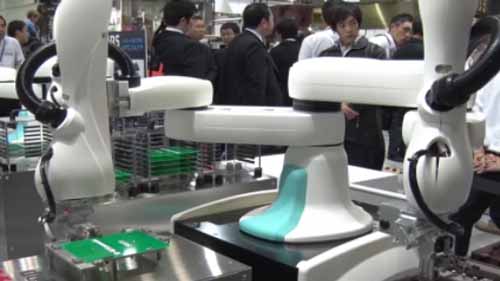

In a bid to capitalize on the gains on the original scara robot design, scara robot manufacturers created the dual-arm scara robot. If you would like to add one to your production line, here is what you need to know about dual-arm scara robots.

What is a Dual-arm Scara Robot?

Source: Pinterest

A dual-arm scara robot is a single robot that has 2 scara robotic arms mounted on one base. They imitate the motions of human arms in that they can work independently or coordinate to fulfill tasks.

Features of a Dual-arm SCARA Robot

Compared to an ordinary scara robot, a dual-arm scara robot has unique features and capabilities. They include:

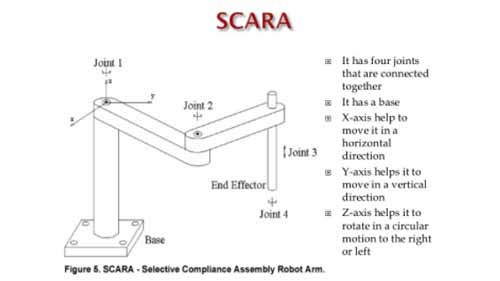

Axes

Source: Slideshare

At present, each of the arms on dual-arm scara robots is a 4-axis robotic arm.

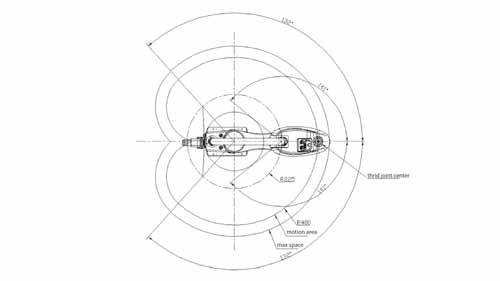

Arm Reach

The current models of dual-arm scara robots have an arm reach of between 150mm to 550mm. This allows them to cover a significant work envelope to complete a variety of tasks.

Compact Design

The two arms of a dual-arm scara robot are joined to a single base mounted on a trolley. It is a compact design that only takes up about as much space as one individual. That said, when allocating space for the robot in relation to human workers, it is advisable to consider arm reach.

Payload

Each arm is allocated an equal payload to the other. Due to this, when one arm works individually it carries a lesser load than when both arms coordinate. For example, if the payload is 2Kgs for each arm when they work together, they can handle a 4Kg load. The models that are presently available in the market have payloads of between 2-3Kgs.

Collaborative Features

Source: robotics.org

Dual-arm scara robots are designed to share their work environment with human workers. To this end, they have in-built collisions sensors to detect obstacles. Whenever a worker or foreign obstacle enters their work envelope, the sensors trigger the robot’s arms to stop. The arms are also built using soft material that reduces collision impact.

Easy Teaching and Programming

For easy setup, a dual-arm scara robot arm can be taught using tablet software. The software has a standard list of operations which when activated, direct the robot to fulfill particular tasks.

Take, for example, that a worker is setting up the dual-arm scara robot for gate cutting. They would:

- Situate the robot at the required workspace

- Choose the ‘Gate cutting’ application

- Enter the requisite measurements for the procedure

Once the parameters are entered the robot will be guided by the software throughout the process. If the parameters are changed, the robot will change its tooling accordingly.

Easy Installation

The compact dual-arm scara robot is mounted atop a portable trolley. This allows for the robot to be placed wherever it is needed in the production line and relocated just as easily. Alternatively, the robot can be unmounted from the trolley and connected using cables where necessary.

Applications of Dual-arm Industrial Robots

Source: denso-wave.com

The dual-scara robot arm can be applied in various industrial operations including:

Quality Control

Dual-arm scara robots can be used as material handling robots alongside vision inspection procedures of FPC boards and similar items. It works as follows:

- One of the robot arms is fitted with a scanner

- Both arms work to pick and place the FPC on a scanner board

- The arm with the scanner runs a vision inspection

- Both arms lift the FPC off the scanner board

This type of robot has also been successfully applied in testing touch screens and computer keyboards using suitable end-effectors.

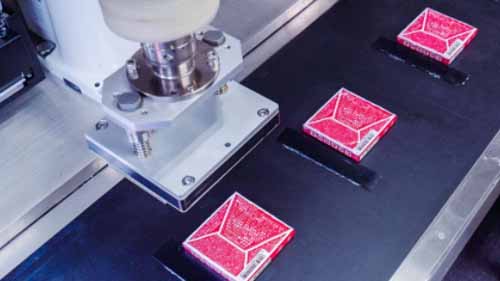

Automated Labelling

Source: irls.hk

In this application, one robot arm picks up the product to be labeled and places it on a central surface. The second arm collects a label from a dispensing machine and places it on the product. The first arm then returns the labeled product to the tray and collects another until the whole batch is labeled.

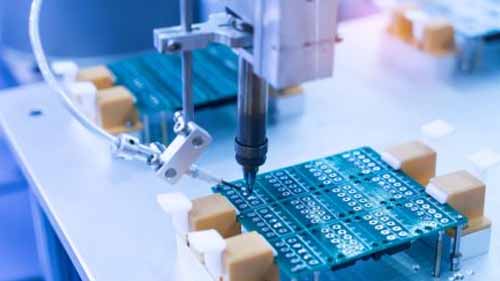

Assembly of PCB Parts

Source: etftrends.com

PCB boards require careful handling during part installation so as not to interfere with other components. A dual-arm scara robot achieves this flawlessly. It works as follows:

The first arm collects the parts to be installed using an end-effector

The robot arm sensor checks for flexibility of the PCB part to discern where to place it

During placement, the second arm guides the first arm and holds it in place to complete the installation

Conclusion

The capabilities of a dual-arm scara robot are certainly a great addition to the robotics industry. They will likely gain popularity quite fast due to their dexterity and multiple applications. It will equally be interesting to see what new features industrial robot manufacturers will come up with going forward.

Also Read:

Painting Booth | Robotic Spraying | Auto Parts Painting

Painting Robot Price|Painting Robot Arm|Spraying Painting Robot