The way that manufacturing companies achieve high-precision welding has changed as a result of the integration of robotics and laser welding robots. These technologies are essential in contemporary industrial environments because they improve weld quality, expedite output, and lower human error. Robots that automate the welding process, such as laser welding robots, provide unparalleled accuracy, and robotics in production guarantees that intricate jobs are completed effectively and reliably.

Robots that Weld Lasers: Their Use in Manufacturing

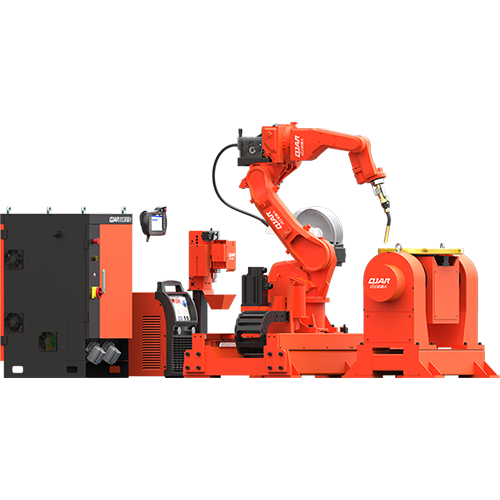

Robots for laser welding are made to weld accurately and quickly while causing the least amount of heat distortion possible, guaranteeing solid and reliable joins. They can perform sensitive welding jobs in the automotive, aerospace, and electronics sectors because to their sophisticated sensors and control systems. For instance, laser welding robots may accomplish precise alignment without the need for human assistance by performing complex welds on tiny components.

By automating the process, reducing the need for rework, and guaranteeing product homogeneity, integrating robotics into manufacturing using laser welding robots shortens production times. Throughput is increased, allowing businesses to effectively achieve production requirements.

Advantages of Laser welding robots for Manufacturing Robotics

There are several advantages to combining robotics with laser welding robots in manufacturing, such as increased productivity, increased accuracy, and increased safety. Laser welding robots produce reliable outcomes with a regulated welding process, greatly lowering the possibility of mistakes. Furthermore, the unpredictability that comes with human welding is eliminated in manufacturing by robotics, which makes it perfect for high-precision sectors.

For example, automated material handling and component positioning are made possible by the smooth integration of laser welding robots with robotics in manufacturing systems. Each weld is done equally thanks to this synergy, which also guarantees a flawless finish and fewer flaws on every product.

How Manufacturing Robotics Increases Productivity

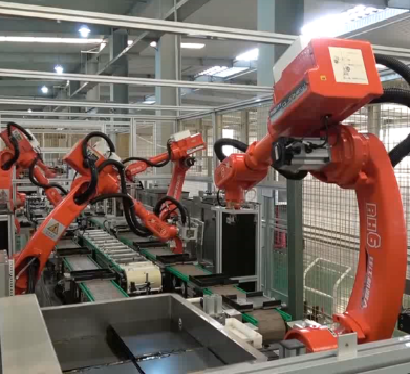

Robotics in manufacturing increases production efficiency by automating welding and component handling, two complicated activities. As a result, producers are able to create more units in a shorter amount of time due to reduced cycle times. By producing accurate welds quickly, the integration of laser welding robots into the manufacturing line further improves the workflow.

Robotic arms, for example, can be used in production systems to manipulate parts and enhance the precision of laser welding robots. Manufacturers establish a smooth operation that reduces downtime and optimizes productivity by automating both the welding and handling processes.

Advanced Robotic Laser Welding Features

Robots for laser welding have a number of cutting-edge characteristics that improve their manufacturing robotics performance. Real-time monitoring and modifications are possible because to the advanced sensors, vision systems, and programming skills that these robots possess. These characteristics are essential for preserving the quality of the weld, particularly in situations when accuracy is vital.

Greater flexibility is also ensured by integrating these robots with robotics in industrial systems since laser welding robots are easily reconfigured to perform various jobs. The capacity to adapt is crucial for businesses where regular modifications to product designs or standards are necessary, which is why laser welding robots are an invaluable tool in contemporary production.

Robotics’ Effect on Product Quality in Manufacturing

The notable enhancement of product quality is among the primary benefits of robots in the industrial sector. Manufacturers may guarantee that every weld is completed precisely by employing laser welding robots, doing away with inconsistent results from manual procedures. Stronger welds and fewer flaws are the outcome, producing goods of a higher caliber.

Robotics in manufacturing systems also lessen the possibility of human mistake since automated processes can carry out precise repeated operations. This improves brand reputation and customer happiness by guaranteeing that the finished product satisfies industry standards and client expectations.

Future Prospects for Robotics in Laser Welding and Manufacturing

As technology develops, robotics in manufacturing, especially laser welding robots, should become much more advanced. The integration of artificial intelligence (AI) and machine learning will enhance the intelligence of laser welding robots, enabling them to adapt their operations in real-time to data. This will reduce material waste, raise productivity overall, and improve precision even further.

Furthermore, these systems will be able to do increasingly complicated jobs like multi-axis welding and real-time quality checks because to developments in industrial robots. Manufacturers will therefore be able to increase production rates without sacrificing the excellent caliber of their products.

In summary

In conclusion, by improving accuracy, speed, and consistency, the marriage of robotics in manufacturing with laser welding robots is transforming industrial processes. These technologies are crucial for enterprises who want to remain competitive because they simplify processes, cut expenses, and enhance product quality. The combination of laser welding robots with robotics in production will continue to be a major force behind industrial innovation and success as these robots develop. Manufacturers may gain increased productivity and establish new benchmarks for product excellence by investing in these cutting-edge solutions.