Are you sure that your food is safe? From farm to fork, there are many potential hazards. One of the most important checkpoints is during the packaging process. In the fast-paced world of today’s food industry, maintaining hygiene during pick-and-place operations can be a challenge. What if there were a way to revolutionize food safety while maintaining efficiency?

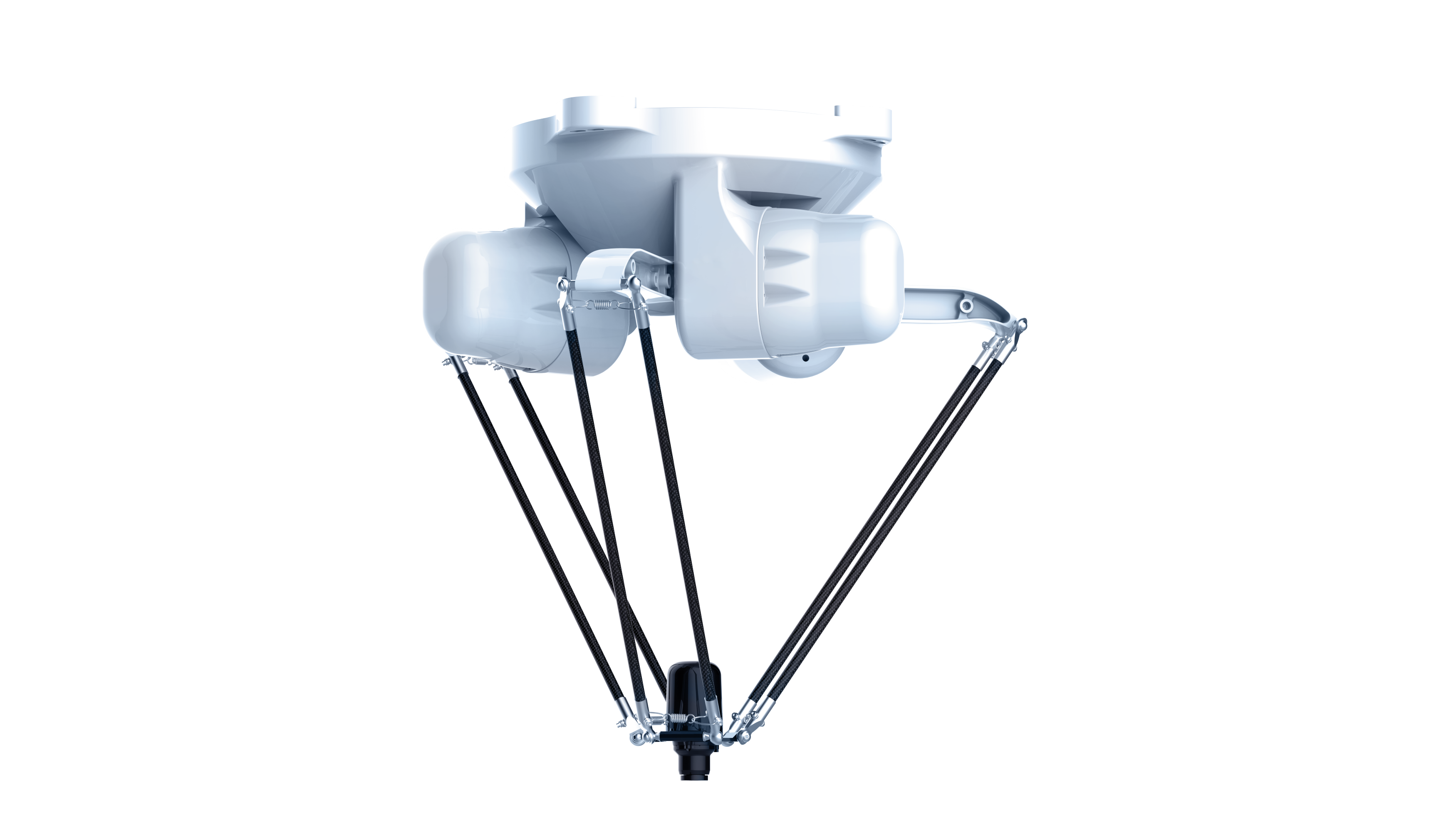

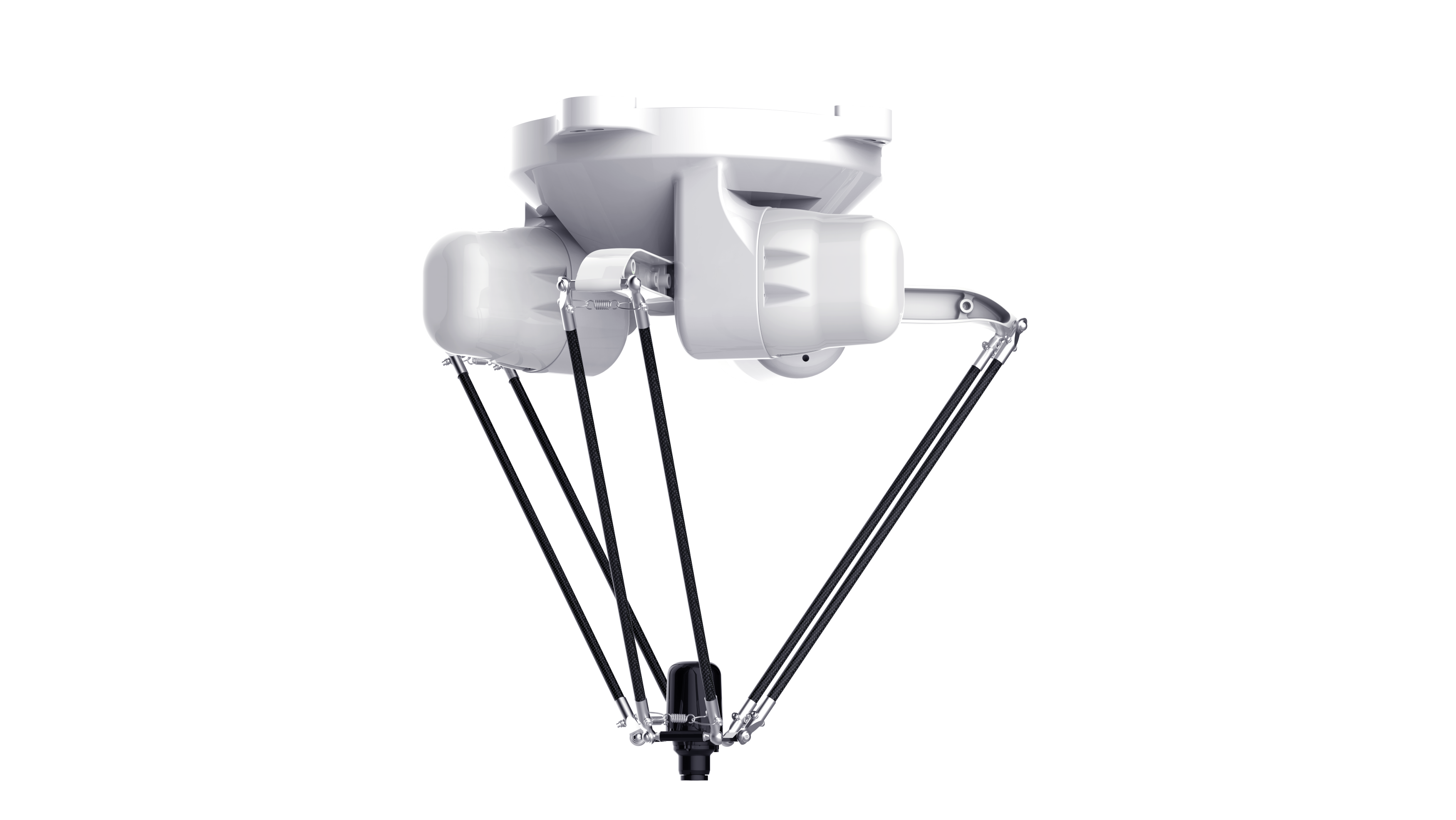

Enter the world Delta Robots, the unsung heroes in hygienic packaging. These spider-like machines, which are sleek and elegant, protect your health by working to make sure that each morsel on your plate is free of contamination. Delta Robots, with their lightning-fast movement and precision control are changing the face of food safety one package at a.

This blog will explore how Delta Robots is tackling the food safety issues head on. We’ll explore the reasons why these machines have become indispensable in modern food-processing facilities. We’re about to embark on an exciting journey as we explore the five aspects of Delta Robots that makes them the leaders in food safety for pick-and-place operations.

Pick and Place operations: Food safety challenges

Common contamination risks

-

Physical contaminants (e.g. metal fragments)

-

Biological hazards

-

Chemical contaminants

| Risk Type | Example | Preventive Methods |

|---|---|---|

| Physical | Metal and plastic | Metal detection, visual inspection |

| Bio | E. coli, Salmonella | Sanitization, temperature control |

| Chemicals | Cleaning residues | Use of safe chemicals and proper rinsing |

Regulations for food processing equipment

The equipment used to process food must adhere to strict standards of hygiene set by regulatory agencies. This includes using materials that are food-grade, designing easy-to-clean products, and performing regular maintenance. These requirements are crucial to maintaining food safety, and avoiding legal issues.

Delta Robots have a Hygienic Design.

Materials and coatings of food-grade quality

Delta robots are used in the food processing industry to use FDA-approved materials such as stainless steel and food grade plastics. These materials are resistant to corrosion and chemical reactions. This ensures product safety. These coatings create smooth, nonporous surfaces which inhibit bacteria growth and make cleaning easier.

Structures that are easy to clean

| Features | Benefit |

|---|---|

| Smooth surfaces | Prevent bacterial buildup |

| Round edges | Eliminate hard-to-clean corners |

| Minimum crevices | Reduce contamination risks |

The Delta robots have been designed to be hygienic.

-

Open Structures for Easy Access

-

Quick-release components to thoroughly clean

-

Self-draining design to prevent water accumulation

Precision and speed can improve food safety

Avoiding human contact with food

Delta robots reduce the risk of contamination by reducing human contact with food products. These robots are able to handle delicate items with no direct human contact, which ensures a more hygienic procedure. Delta robots automate pick-and-place operations to create a barrier that separates human operators from food products.

Reducing product handling time

| Benefit | Food Safety |

|---|---|

| Faster processing | Exposure to contaminants is reduced |

| Efficient sorting | Reduces spoilage risk |

| Precise placement | Minimal product damage |

The speed and precision of Delta robots reduce product handling time dramatically, improving food safety. Rapid processing minimizes contamination and spoilage risks.

Delta Robots: Maximum Hygiene with Delta Robots

Integrate with existing food safety protocols

Integrating Delta robots seamlessly into existing food safety protocols for maintaining hygiene standards is essential. These robots will enhance current practices in:

-

Reduce human contact with food

-

Improve traceability

-

Consistency in handling

| Aspect | Traditional Method | Delta Robots |

|---|---|---|

| Speed up | Slower, variable | Consistently faster |

| Hygiene | Contamination is a possibility | Minimal contamination risk |

Staff training on maintenance and cleaning

Training is essential to ensure that staff maintains and cleans Delta robots efficiently, while maintaining hygiene standards. The following are key training areas:

-

Cleaning robot components

-

Proper sanitation techniques

-

Troubleshooting common problems

-

Documentation of cleaning processes

Staff are kept up-to-date on best practices through regular refresher training.

Case studies: Hygiene improvements with Delta Robots

A. Applications for the dairy industry

Delta robots revolutionized hygienic practices in the dairy industry. After implementing delta robotics in packaging, a major cheese producer reported a reduction of 30% in contamination incidents. The high-speed operation of the robots minimized the product’s exposure time while their easy to clean design allowed for thorough sanitization.

B. Meat processing advancements

| Improve your life with the help of | Before Delta Robots | After Delta Robots |

|---|---|---|

| Contamination | 5% of all batches | 1% of batches |

| Processing Speed | 100 units/min | 250 units/min |

| Cleaning Time | 2 hours daily | 30 minutes daily |

Delta robots are revolutionizing pick-and-place operations in the food sector, while also addressing food safety issues. These robots are designed to be hygienic, reducing contamination and ensuring compliance with strict food safety standards. Delta robots are fast and precise, which not only increases productivity but also decreases human contact with foodstuffs.

Delta robots are a great addition to food processing facilities, but they require careful planning and integration. Numerous case studies have shown that companies who have adopted these advanced robot solutions have seen significant improvement in hygiene standards and food safety. Delta robots can help food manufacturers improve their safety protocols and protect the health of consumers while maintaining a competitive advantage in a market that is becoming increasingly demanding.