Pick and place robotic arms are rapidly changing the dynamics found in the workplace. This is mainly because they are replacing human hands in handling repetitive tasks and other operations that don’t require human intervention.

This development comes with its benefits and helps businesses get work done faster and increase productivity. It also allows the staff to focus on other more important tasks that drive your business to achieve greatness.

Embracing pick and place automation in the workplace will significantly increase your work output and also reduce costs incurred.

However, before you decide to invest in a pick and place arm, it is important to do your research. This research will better inform you of how this addition will benefit you as a business. Here are a few things you should know about this essential investment.

Advantages of Pick and Place Robot Arms

For most people, embracing new technology in their business may be a big leap out of their comfort zone. However, with the advantages attached to pick & place robots, you’ll be more inclined to invest. Here are a few benefits to consider.

Speed

Seeing as these are robots you can be sure that tasks will be completed with speed and always on time. This is because they don’t get tired and neither do they need the constant breaks taken by humans. They get to work non-stop if need be which ensures that there’s a fast turn around time on all products.

Consistency

The common human errors experienced when working for long hours is greatly minimized. Pick and place industrial robots are consistent in the results they produce each time.

This is mainly because they are programmed to do tasks in a certain way. Doing this allows them to maintain consistency and ensure that work is done in a standard that carries on from one product to the next.

Enables Multiple Application

Thanks to the fact that these pick and place arms are programmable, they can be used in different applications.

All that is needed is to program the robot to achieve the results you want for that particular task. This allows them to be multi-functional which means you don’t have to invest in different industrial arms.

Increased Work Output

With the speed and efficiency that is exhibited by pick n place robots, you can be assured of the fact that your work output will significantly increase.

You’ll be in a position to get more work done compared to when relying on human efforts.

Feature a Great Return on Investment

Given that these robots are fast and increase work output, you are assured of a great return on investment.

Also, the fact that human effort is reserved for other more important tasks, you’ll achieve more. It will also ensure that your employees are motivated and not worn out by repetitive tasks.

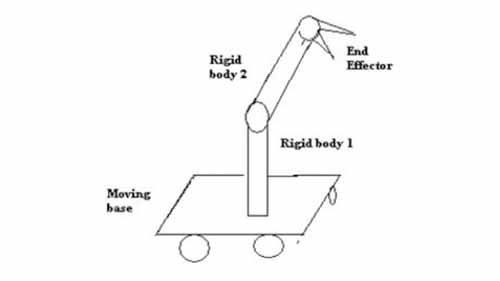

Pick and Place Robot Arm Design

Source: elprocus.com

Pick and place arm’s designs will vary depending on its intended applications. However, a few things will remain constant and present in all the designs. Some of these things include:

Joints

Joints are used to join the two rigid bodies that make up a pick and pace arm. These joints make it easier for these robotic arms to achieve easier movement. The joints determine the degree of freedom in terms of movement. Joints used could either be linear joints or rotary joints.

Arm

The arm is supported by a rigid body that helps it make the necessary movements. It also features some grippers.

Base

The base is used to provide support to both the arm and the manipulator. This ensures that the pick and place arm is sturdy and efficient.

Grippers

This is what is used to pick items and place them in the required destination. These grippers come in different sizes and strengths. This depends on what they are intended to be working on.

Manipulator

This is the body that supports the arm and directs it in the right direction. It heavily depends on the joints since they are the only movable components.

Controller

This is essentially the brains of the operations. This is because the controller is used to record the movements of the arm, keep track of time, and also the position of the arm.

This helps ensure that the operation runs smoothly. It features a few options including, Mechanical, Hydraulic type systems, and also Electrical. Whichever one you decide to go with is a personal preference.

Applications of Pick and Place Arms

Pick and place arms are made to be diverse and are used in different industries. This means that their applications will range depending on where they are used. Here are a few applications that apply pick n place robots.

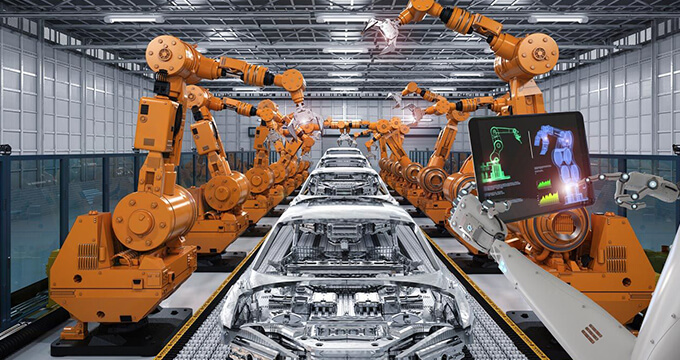

Industrial Application

When it comes to the daily operations in industries, such robots come in handy. They help increase work output, productivity, and also efficiency. This is why they are fast being embraced and are in high demand given the benefits they bring. Industries use pick & place robots to do a few things. They include:

Assembly

The precision exhibited by pick and place arms allows them to conduct fast assembly. They pick parts from the conveyor and assemble them to create working products. This helps operations run faster as compared to using humans for these tasks.

Inspection

Ensuring quality control is important for all industrial operations. This is because you need to ensure that all your products are consistent and of great quality, if you want to attract and retain customers.

With this in mind, investing in a pick and place robot arm will help you achieve this. They can visually inspect products moving in a fast conveyor belt. If any product doesn’t meet the requirements, they are then removed making this process very important.

Sorting

Pick and place industrial robots are very efficient and fast when it comes to the sorting process. If you need to sort parts and separate them into categories, then your industrial robot will make things easier and faster.

Packing

These robots can pick items from a conveyor and pack them into their respective places at very high speeds.

Defense Application

Source: engineering.eckovation.com

The preservation of human life on the battlefield is an area of great concern which has led to the adaptation of pick and place robots. These robots are used to pick harmful weapons like bombs and safely disarm them.

This helps to reduce the loss of life and also the human errors that may occur because of being panicked. These robots also come in handy when conducting surveillance operations on enemy territory.

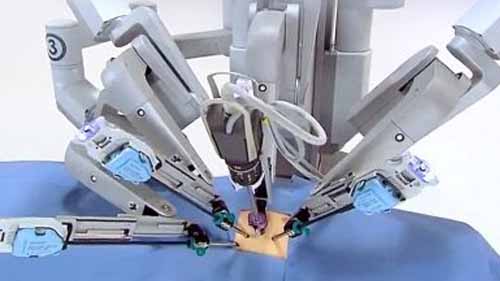

Medical applications

Source: engineering.eckovation.com

In everything we do, human error is a major player. This also applies to the medical field where mistakes may occur during an operating procedure. To reduce such risks, the use of pick and place arms may be adopted.

This is because these robots can be used to perform various surgical operations including internal surgery, joint replacement, and more. Pick and place robotic arms will work with more precision and accuracy compared to human hands.

Pick and place robots in the medical industry also come in handy when applied to the manufacturing, assembly, and packaging of different medical equipment and drugs. They help ensure consistency of quality and also increase the pace at which this is achieved.

Food Applications

Source: engineering.eckovation.com

The food industry has also welcomed the use of pick and place arms when packing different foods. This is mainly because they help reduce the risks for contamination and also ensure a fast packaging process. The advantages of using pick and place arms in the food industry are unmatched.

Also, seeing as these are robots, you won’t have to worry about the quantity. They’ll ensure everything is packed equally.

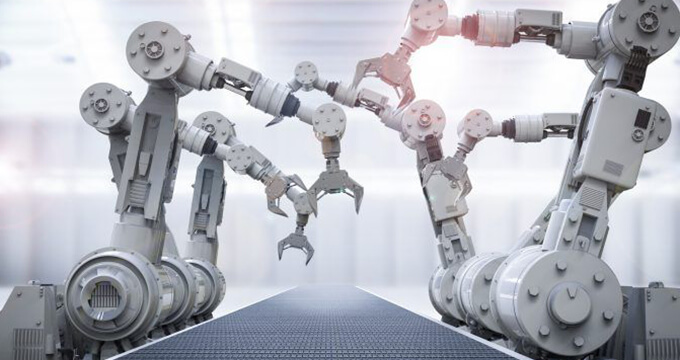

How do Pick and Place Arms Benefit Manufacturers?

Source: engineering.eckovation.com

As a manufacturer, you may be wondering why you need to invest and embrace such technology. It’s simple really, the benefits you’ll encounter will make the case for you. Here are a few benefits you’ll enjoy as a manufacturer in whatever field.

Speed

One of the main reasons you should adopt pick and place robots to automate your operations is because of speed. The speed exhibited by these robots allows your productions to triple or even quadruple compared to when depending on humans.

In theory, pick and place arms are said to handle over 130,000 components per hour. With that in mind, imagine the amount of speed they must have to get to such a goal. What would you achieve if this was the speed at which your operations were running?

Consistency

As a manufacturer, producing substandard products only leads to the loss of clients and a bad reputation for your business. This is why you need to strive for accuracy and precision in all your operations. This will ensure that your products are consistent. Pick and place arms will help you achieve this with ease.

They are programmed to achieve specific results with very little margin of error. This means that the products will be of quality standards and you won’t have to worry about your reputation or clients.

Flexibility

The application of pick and place robots provides a great deal of versatility and flexibility in that you can program it to do different things.

This means that you can use these robots to handle different movements, directions, and any other specifications you want. They can also work with components of different sizes and shapes without compromising on the quality of work done.

Cost savings

The use of pick and place arms will automate a lot of operations in your manufacturing factory. This will go a long way to streamlining your business operations.

The speed and efficiency that is exhibited by these robots will help reduce costs incurred significantly. They’ll be an expensive purchase for sure however you’ll quickly recover your investment. Not to mention, the return on investment will be through the roof.

Robots for Pick and Place Robot Projects

Different robots can be used on pick and place projects. They differ because they come with different features and are made in various ways. The main types of pick and place robots include:

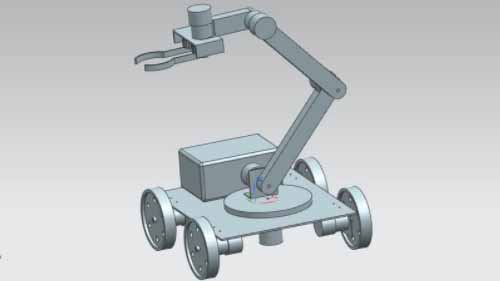

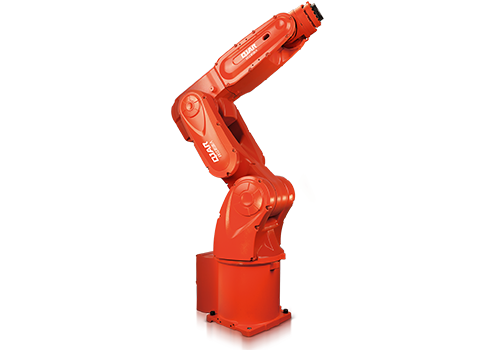

Robotic arms

Source: skyfilabs.com

These arms are commonly referred to as pick and place robot arms. They are the most used robots when it comes to pick and place projects. They feature both 5-axis robotic arms and 6-axis robotic arms.

For the standard pick and place projects that require a pick-up and deposit in one single pane, the 5-axis works best. However, the 6-axis is meant for more complex tasks like re-orienting the product before placing it in the desired location.

Cartesian

Source: assemblymag.com

The cartesian robot comes with its coordinates and works in 3 orthogonal axes ( X, Y, and Z). It is used to move large and heavy objects from one point by picking them and placing them in a different location. They are made using any type of linear actuator and other drive mechanisms that make it more efficient. Its accuracy in positioning is quite impressive making it a great option for pick and place projects.

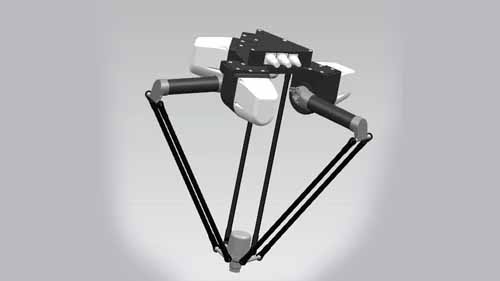

Delta

Source: labelongpack.en.made-in-china.com

Delta robots feature great vision that helps them distinguish different colors, shapes, and sizes. They come with three arms that operate in four axes. These arms are joined to linking rods using joints and are supported by a heavy motor. These robots are best used to pick items in groups or stacks and place them in containers.

Fast pick

Source: directindustry.com

These robots work best when you’re targeting completion with high-intensity volumes. They are used to completely automate processes in the industry reducing the need for human intervention. They are best suited when taking items from the top and placing them in their respective places.

Collaborative

Source: robots.com

With these robots, processes are not fully automated seeing as the work hand in hand with humans. They act as a guide to what needs to be done and how it should be accomplished.

Work done will not have a fast turnaround time as compared to its other robotic counterparts. It is however a good option seeing as the accuracy and efficiency are still going to be on point.

How to Choose the Right Pick and Place Robot

Seeing as using pick and place robots comes with cost-effective advantages, investing in them is a great choice. However, with the many options and different configurations available in the market today it might get a little confusing.

To make choosing easier for you. Here are a few things you need to put into consideration. These things will help ensure that as you consult with pick and place robot arms’ suppliers you won’t make the wrong choice. These things include:

Number of Axes

Source: esunrobot.en.made-in-china.com

Pick and place robots come with different numbers on their axes levels. These numbers range from 4 onwards. This difference is an indicator of the tasks that the robot is meant to perform with accuracy and efficiency.

The number of axes is what determines the degree of freedom when it comes to movement. This means that the higher the number, the more the robot can move with ease.

For pick and place robots with 4 or 5, they tend to be more suited for tasks that only involve picking and placing components. 6 onwards are robots that need to move a lot with no restrictions to easily achieve their aim.

Reach

Source: blog.technavio.com

As you consider investing in pick and place automation, reach is one of the most important factors to keep your eye on. This will help you determine which industrial robot works for you.

Reach in this case is used to refer to the maximum distance that your pick and place robot arm can reach. This applies to the distance both vertically and horizontally. Consider the area that you want to situate your robot and measure it accurately.

When going to make your purchase you’ll be better informed on how far it needs to reach. You’ll then get a pick and place robot that fits your measurements. This will help you ensure that you keep up with your precision and accuracy without compromise.

Speed

Pick and place robots come with different speeds indicated on them from 0 to maximum speed. These speeds let you know how fast operations will be running in your establishment. The speeds are indicated in degrees and would require you to have a clear understanding of how fast operations are currently.

You should then invest in a pick and place robot that exhibits the same speeds or higher to help improve your work output. You should also make sure that the maximum speed on your robot can handle the demand during peak seasons.

Repeatability

Source: Alibaba

For the best results, your robot needs to exhibit the ability to pick and place items at the same place each time. This is what we refer to as repeatability. It comes with high precision and a zero-tolerance radius for any mistakes.

Figure out what your tolerance radius is and invest in a robot that will help you stick to that. Especially for tasks that don’t require pristine precision you can get away with having your tolerance radius at 0.5mm.

Configuration and Vision

Source: Pinterest

Some pick and place robots will come with vision enabled and others will feature configurations that may be harder for you to understand.

This means that you need to go back to your requirements and see what you can tolerate. Figure out which configurations work for you and get the robot that fits that specific feature.

Payload

Having a pick and place robot arm is meant to automate tasks and make things easier for your business. This can only be achieved if you pay attention to the payload. The payload is used to refer to the maximum weight that your robot can transfer from one place to another.

This weight is inclusive of the item being moved and the effector/ gripper in use. You need to work on ensuring that your robot can comfortably handle the heaviest load in your business without any movement problems. Once this is achieved, you’ll have found your perfect pick and place robot.

How Much Does a Pick and Place Robot Cost?

Source: Unsplash

Due to low labor supply and the need to avoid wastage of energy on mundane tasks, the use of pick and place robots is quickly gaining momentum. Most people as they consider whether they’ll take the leap and invest, are often concerned about the costs they’ll incur.

By costs, we are not only referring to money but also time and effort. When it comes to time and effort, you’ll not need much. Installation is quite fast and once installed, the robots can begin work immediately. This will help you save on time and ensure that you start reaping the benefits of your investment as soon as possible.

When it comes to the monetary value, you’d expect it to be over the top. Seeing as these robots will work with no breaks and ensure precision, accuracy, and efficiency that would be justified.

However, these robots will only require an investment of a few thousand dollars depending on the type of pick and place arm you want. They mostly range from 25,000 to 140,000 USD.

After the initial investment, you can be assured of a great return on investment. This makes it an essential part of business operations in whichever field you’re in. Remember, the cost will vary greatly depending on the pick and place arm manufacturer you choose. Do your research and find the best in the market.

Where to Buy Pick and Place Robot Arms

Having ‘pick and place arms in your business to make operations run smoothly and achieve a tremendous streamlined system is an essential investment. An investment that requires you to do the necessary research to find out where to get your perfect pick and place robot.

With this, you have the option of going directly to renowned pick and place robot arms manufacturers, making your purchase online, or at a supplier near you. Whatever you choose to go with, just be sure that you do your due diligence.

Ensure that you check out who your manufacturers have worked with. If they’ve worked with established brands you can be sure that your product will be of great quality. When working with online purchases, make sure that you have a look at other people’s reviews of the robots they got.

This will give you a better understanding of whether to trust the seller or not. With your local supplier, try your best to physically go to the location to see and test out the robot arms yourself. Don’t be hasty, take your time to ensure that you invest in a robot that will benefit you and your business in the long run.

Conclusion

The need for human labor is rapidly decreasing and paving the way for the use of pick and place robot arms. These robot arms have proven to be more effective and accurate making the operations in businesses swift, fast, and streamlined.

As the years go by, the use of robotic arms will be fully integrated with different industries increasing their productivity.

With everything you know now about pick and place arms, what do you think about them? Would you invest in this technology for the growth of your business?

Also Read:

Painting Booth | Robotic Spraying | Auto Parts Painting

Painting Robot Price|Painting Robot Arm|Spraying Painting Robot