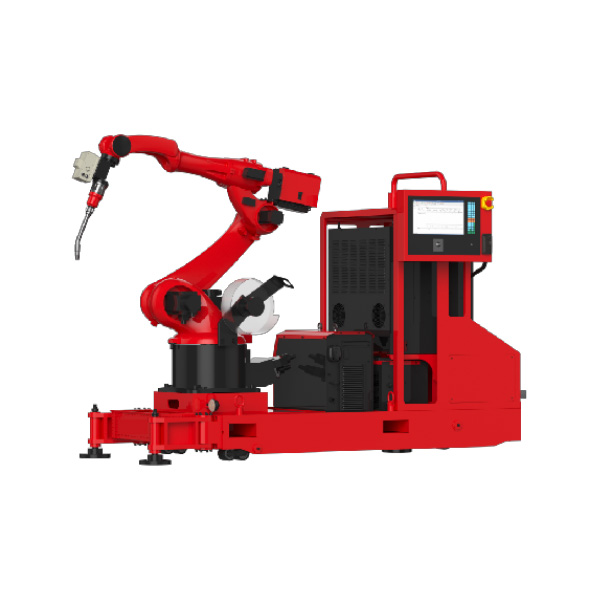

EVS offers advanced robot welding machines and cutting robots designed to boost efficiency, flexibility, and precision across a range of welding and cutting applications. Equipped with cutting-edge technologies like 3D vision recognition and AI for seamless adaptation to complex scenes or challenging tasks.

Robot Welding Machines

Series Overview

- EVS-UW Series: Includes the standard EVS-UWS11V10 and the lifting model EVS-UWL15V10, with powers of 36KVA and 37KVA respectively. These models feature a three-wheel drive system, wireless remote control, and a walking speed of 4km/h. The lifting model offers an additional 700mm lifting stroke.

- EVS-C Series: Comprises the standard EVS-CS14V10 and the lifting model EVS-CL14V10, with powers of 36.5KVA and 37.5KVA. These models are designed for harsh environments and feature a track drive system with a walking speed of 1km/h.

- EVS-H Series: Features the standard EVS-HS15V10 and the lifting model EVS-HL15V10, with powers of 50KVA and 51KVA. These models offer a steering wheel drive and laser radar control, with a walking speed of 2.2km/h.

- EVS-M Series: Includes the standard EVS-MS15V10 and the lifting model EVS-ML15V10, with powers of 50KVA and 51KVA. These models are equipped with Mecanum wheels and laser radar control, providing precise omni-directional movement.

- EVS-DW Series: The EVS-DW10V10 model has a power of 30KVA, a compact design, and a walking speed of 2.5km/h, making it ideal for narrow spaces.

- EVS-FW Series: The EVS-FW16V10 model has a power of 30KVA and is designed for narrow spaces with a walking speed of 2.5km/h.

Common Features

- Workpiece Flexibility: All models allow for flexible workpiece placement without the need for precise fixture positioning, increasing operational efficiency and reducing setup time.

- High Mobility: Equipped with powerful batteries and wireless remote control (or manual control for EVS-FW), these machines offer excellent mobility, making them highly adaptable to different workshop layouts and outdoor operations.

- Low Ground Requirements: Suitable for workshops and outdoor environments with varying ground conditions, reducing the need for extensive infrastructure modifications.

- 3D Vision Recognition: Utilizes advanced 3D vision technology to scan workpiece models and extract weld seam information automatically, eliminating the need for manual programming or teaching.

- AI Technology: Leverages AI and machine vision to achieve “see-and-weld” capabilities, precisely identifying weld seams and adjusting parameters autonomously to enhance welding intelligence and automation, making it ideal for complex and challenging welding tasks.

Robot Cutting Machines

Series Overview

- EVS-UC Series: The EVS-UC model has a power of 47KVA, a three-wheel drive system, and a walking speed of 4km/h. It features a lifting stroke of 1000mm, making it suitable for cutting large tanks and performing bevel cutting.

- EVS-TS Series: The EVS-TS10V10 model has a power of 60KVA and a track wheel drive system with a walking speed of 1km/h. It is designed for multi-position tasks along a track and features autonomous scanning and path planning for cutting operations.

Common Features

- Workpiece Flexibility: Allows for flexible workpiece placement without the need for precise fixture positioning, increasing operational efficiency and reducing setup time.

- High Mobility: Equipped with powerful batteries and wireless remote control, these machines offer excellent mobility, making them highly adaptable to different workshop layouts and outdoor operations.

- 3D Vision Recognition: Scans workpiece models to identify cutting paths automatically, reducing setup time and increasing productivity.

- AI Technology: Employs AI to plan and execute cutting paths based on the workpiece’s geometry, ensuring precise and consistent cuts even in complex scenarios.

Conclusion

These cutting edge robot welding and cutting machines were specifically developed with intelligent features in order to meet the demanding manufacturing environment. Mobile, they enable convenient deployment across different workshop spaces with ease. These unique robots feature an easy, no-programming user experience for maximum precision, flexibility and adaptability across a wide variety of industrial settings. No matter if it be for on – site fabrication in large construction projects, or more agile manufacturing operations with restricted spaces. Intelligent mobile no-programming machines offer reliable solutions tailored to significantly increasing productivity and quality levels while improving overall productivity & quality levels, giving businesses an edge in today’s fast – moving industrial landscape.

For more information on the Mobile Intelligent Vision Welding / Cutting Robots, please visit: https://www.evsint.com/product-category/mobile-intelligent-vision-welding-cutting-robot/