Introduction

The landscape of logistics is constantly evolving, driven by technological advancements that aim to increase efficiency, reduce human error, and minimize costs. Among these technologies, six axis robots have emerged as pivotal players. Originally designed for simple repetitive tasks, these robots are now pivotal in transforming logistical operations through their flexibility and precision. Particularly, the 12kg payload, 1300mm reaching distance six axis collaborative robot (cobot) stands out with its capability to handle, palletize, and even perform arc welding. This cobot exemplifies the shift towards more dynamic and versatile applications in logistics, providing high reliability and excellent performance, even in constrained spaces. The purpose of this article is to delve into the advanced applications of six axis robots in logistics, moving beyond their traditional uses.

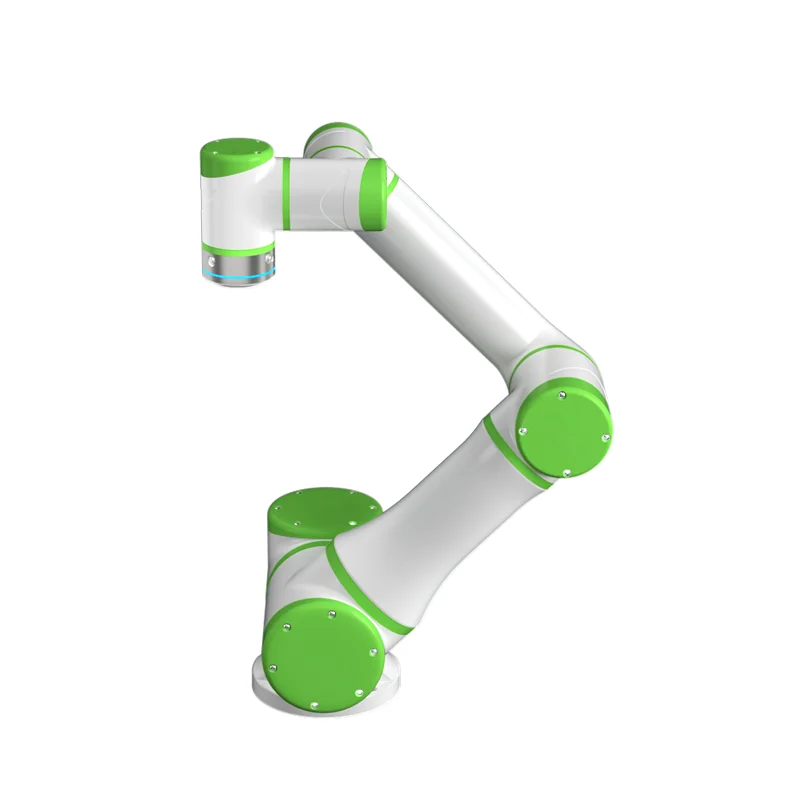

Understanding Six Axis Robots

Six axis robots, characterized by their six points of rotation or “joints,” offer a remarkable range of motion that mimics a human arm. This makes them incredibly versatile in industrial environments. The cobot model R12-135S, for example, boasts a significant payload capacity of 12kg and an armspan of 1300mm, combined with a wide range of motion in each joint (±360° in most). These technical capabilities enable the robot to perform complex tasks with precision, having a repeat positioning accuracy of ±0.02mm and speeds up to 240°/s per joint. In the context of robotics in logistics, the advantages of such six axis robots include their ability to adapt to different tasks, enhance precision in placement and handling, and significantly boost overall logistical throughput.

Traditional Uses of Robotics in Logistics

Traditionally, six axis robots have been staples in logistics for performing tasks such as handling materials, palletizing goods, and executing pick-and-place operations. These tasks are foundational in warehouses, distribution centers, and manufacturing facilities where speed, accuracy, and repeatability are paramount. Six axis robots excel in these areas by reducing the time it takes to pack and sort products, minimizing human error, and lowering the physical strain on human workers. The impact of these robots in logistics has been profound, enabling facilities to increase output and operate more efficiently around the clock.

Advanced Applications in Logistics

Beyond their traditional roles, six axis robots are increasingly finding new applications within the logistics sector that require more advanced capabilities and integration with other technological innovations:

Customized Packaging

Six axis robots are now being used for customized packaging solutions. They can dynamically adjust packaging techniques based on real-time data regarding order specifications, which optimizes material usage and reduces waste.

Inventory Management

Integrated with the Internet of Things (IoT), six axis robots can help manage inventory by tracking goods throughout a facility in real time. This application reduces the likelihood of inventory discrepancies and enhances the ability to predict stock needs.

Complex Assembly

In logistic operations that involve the assembly of products or parts, six axis robots can perform complex tasks that require high precision and variability. This capability is particularly useful in just-in-time manufacturing setups that operate within logistical operations.

The integration of AI and machine learning further enhances the capabilities of six axis robots, enabling them to learn from their operations and improve efficiency over time, a critical advancement for robotics in logistics.

Case Studies

Real-world implementations of six axis robots demonstrate their value and versatility:

E-commerce Fulfillment Center

An e-commerce giant has employed the R12-135S model in its fulfillment centers to automate the sorting and packaging process. This implementation has not only sped up operations but also reduced errors and labor costs.

Manufacturing Plant

A major manufacturer integrates these cobots into its supply chain operations to perform complex assembly tasks. This integration has streamlined operations and significantly reduced downtime.

Retail Stock Management

A retail chain uses six axis robots to manage stock in its large distribution centers. The robots perform tasks that include sorting, shelving, and inventory audits, improving accuracy and operational speed.

These case studies highlight the adaptability and efficiency of six axis robots in diverse logistical settings, showcasing their ability to transform traditional practices.

Future Trends and Predictions

The potential for six axis robots in logistics appears bright, as continued progress is expected to increase the scope of their applications. Robotics, AI, and machine learning technological developments will augment these robots’ capabilities and further incorporate them into logistics processes. Unfortunately, there are some disadvantages to integrating such cutting-edge technology. For example, qualified personnel may be needed to supervise and maintain these systems, and cybersecurity risks may arise.

Conclusion

The exploration of advanced applications of six axis robots in logistics reveals a future where these machines do much more than mere pick-and-place tasks. Their ability to adapt to various operations, enhance efficiency, and reduce costs makes them invaluable assets in modern logistics. The function of six axis robots is expected to grow in importance as technology develops, spurring advancements and innovations across the sector. This development highlights the revolutionary possibilities of robotics in logistics, indicating a more intelligent and effective future for the industry.