Introduction

Two technologies—smart logistics and six-axis robotics—have emerged as transformative actors in the dynamic realm of industrial automation. By virtue of augmenting dependability, efficiency, and safety, the integration of these technologies possesses the potential to fundamentally transform an extensive array of sectors. The R12-135S, a six-axis collaborative robot with a 1300 mm reaching distance and a 12 kg payload, is crucial to this integration. Designed to excel at palletizing, picking and placing, arc welding, and pick and place operations. In this article, the benefits and potential future developments of six-axis robotics and smart logistics are discussed in conjunction.

Comparing the Definition and Characteristics of Six-axis Robotics

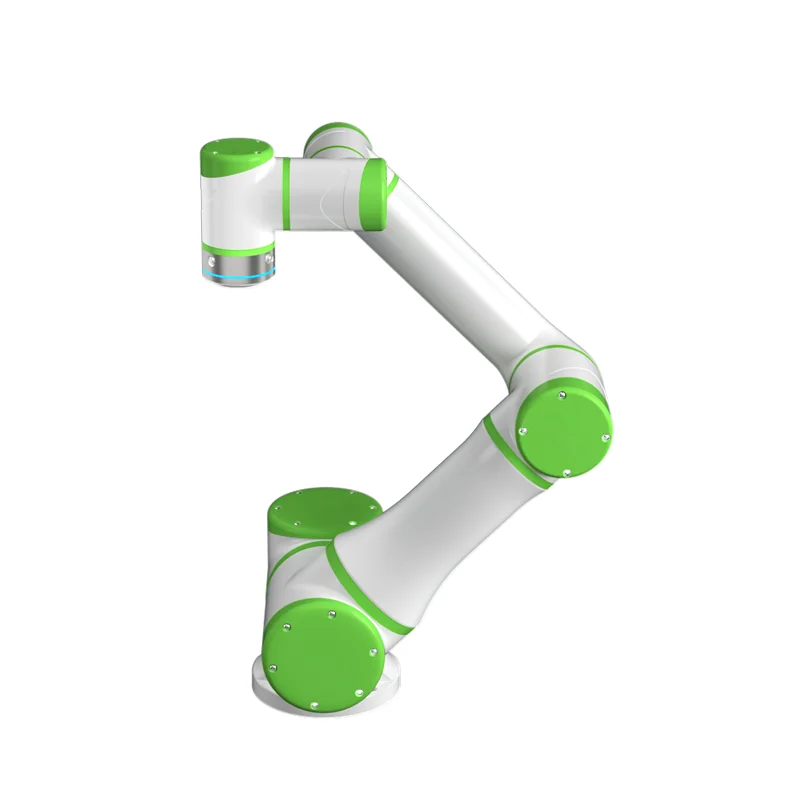

Six degrees of freedom are incorporated into six-axis robots, which are sophisticated robotic systems that permit a broad range of motion and flexibility. Sophisticated in their ability to replicate human arm movements, these robots are well-suited for intricate assignments across diverse sectors. At 12 kilograms in weight and 1300 millimeters in arm span, the R12-135S model exemplifies the capabilities of six-axis robots. The consistent execution of repetitive tasks is ensured by its high precision, which is demonstrated by its repeat positioning accuracy of ±0.02mm.

Implementation Options

Numerous applications can benefit significantly from the adaptability of six-axis robots. They find extensive application in the manufacturing sector where they facilitate material handling, palletization, and accurate pick and place operations. Further, their precision and dependability guarantee the production of welds of superior quality during arc welding. Particularly notable are the R12-135S’s collaborative capabilities, which allow it to execute multiple procedures and operate efficiently in confined spaces. By relieving human laborers of potentially dangerous and repetitive duties, this robot not only increases efficiency but also fosters a more secure occupational setting.

An Overview of Intelligent Logistical

Components and Definition of

By integrating state-of-the-art technologies such as data analytics, artificial intelligence (AI), and the Internet of Things (IoT), the operations of the logistics and supply chain can be significantly improved. By harnessing real-time data to optimize processes and facilitate well-informed decision-making, intelligent logistics systems possess the capability to enhance overall operational efficiency. Intelligent transport systems, automated warehouses, and predictive analytics are key components of smart logistics; they collaborate to create a streamlined and effective supply chain.

The Benefits Include

There are a multitude of extensive benefits associated with smart logistics. As an initial benefit, it substantially enhances operational efficiency through the reduction of manual intervention and the mitigation of errors. Additionally, it minimises waste, optimises inventory management, and optimises routing to decrease expenses. In addition, smart logistics enhances supply chain visibility, allowing businesses to immediately track the whereabouts of goods and respond effectively to any potential obstacles. The impact of intelligent logistics on modern supply chains is significant and transformative, as exemplified by practical instances such as Amazon’s implementation of automated warehouses and predictive analytics.

Intelligent Logistics Integration Benefits From The Synergy Between Six-Axis Robotics

Numerous advantages result from the incorporation of six-axis robots into smart logistics systems. In conjunction with the automation and data-driven decision-making of smart logistics, these robots are capable of executing a wide range of tasks with exceptional accuracy and consistency. An example of the application of six-axis robots in a warehouse environment is the R12-135S, which is capable of sorting packages, manipulating goods, and conducting quality inspections; thus, it optimizes the logistics processes.

Examinations of Cases

The effective incorporation of six-axis robots into smart logistics is demonstrated by a number of case studies. The integration of six-axis robots within the distribution center of a prominent e-commerce corporation serves as a noteworthy illustration. A substantial decrease in order processing time and an increase in overall throughput were the outcomes of automating the picking and packing procedure with these robots. Six-axis robots were utilized for material handling and assembly in a manufacturing facility, as described in a second case study. A more efficient production process and higher-quality products were the results of integrating these robots with smart logistics systems.

Details Regarding the Technical Specifications of the R12-135S Collaborative Robot

Diverse impressive technical specifications characterize the R12-135S collaborative robot. Payload capacity is 12 kilograms, and its net weight is 36 kilograms (without cables). Six degrees of freedom are housed within the robot, facilitating an extensive spectrum of motion. It has joint motion ranges of 165° for joint 3 and 360° for joints 1, 2, 4, 5, and 6. End-of-arm (EOA) velocity is limited to 3 meters per second, while joint velocity ranges from 150 to 240 degrees per second. Repetition and absolute positioning accuracy of the robot are both ±0.03mm and 0.5mm, respectively.

Distinct Attributes

The collaborative spirit of the R12-135S is one of its defining characteristics. By extending their capabilities and allowing them to concentrate on more valuable endeavors, this robot is intended to operate in conjunction with humans. Flexible mounting options permit it to be affixed at any angle, and its lightweight and compact design renders it well-suited for functioning in confined areas. With an average power consumption of 550W, the robot’s control bus/frequency is EtherCAT/1kHz. Moreover, an aluminum alloy frame constructs the R12-135S, guaranteeing its resilience and consistency across a range of operational settings. The suitability of this product for a wide range of applications is further enhanced by its IP65 rating and low noise level (≤60dB).

Prospects and Advancements in the Future

Enhancements to Six-axis Robotics

An ongoing stream of advancements in the domain of six-axis robotics seeks to augment their functionalities and practical implementations. Further progress could potentially involve enhanced accuracy, accelerated motion rates, and increased integration of artificial intelligence and machine learning systems. As a result of these advancements, six-axis robots will be capable of efficiently executing far more complex tasks. In addition, the safety and adaptability of these robots will be further improved through developments in sensor technology and collaborative functionalities, thereby augmenting their worth in industrial environments.

Developments in Intelligent Logistic

Additionally, significant developments are anticipated in smart logistics over the next few years. The effectiveness of smart logistics networks will rise as a result of the adoption of 5G technology, which will enable faster and more reliable device-to-device communication. Furthermore, the integration of blockchain technology will facilitate supply chain transactions with enhanced transparency and security. With the enhancement of AI and machine learning algorithms, intelligent logistics systems will possess the capability to optimize operations in real-time and generate more precise predictions. The precision and adaptability of six-axis robots will allow them to meet the progressively intricate requirements of smart logistics, making their role critical in this dynamic environment.

In summary

An Overview of Principal Arguments

A significant advancement in industrial automation can be attributed to the interaction between six-axis robots and smart logistics. By virtue of their adaptability, versatility, and high precision, six-axis robots are an asset to logistics operations in terms of safety and output. Intelligent logistics, on the other hand, employs state-of-the-art technologies to optimize the operation of supply chain procedures in a strategic and effective manner. The implementation of these technologies yields a multitude of advantages, including heightened supply chain visibility, increased operational efficiency, and reduced expenditures.

Summarizing Reflections

In light of the ongoing adoption of automation and digital transformation across various industries, the integration of six-axis robotics into smart logistics has become unprecedentedly critical. The potential of six-axis robots to considerably transform logistics operations is exemplified by the collaborative R12-135S robot. In a rapidly evolving industrial environment, companies that allocate resources towards these technologies will be strategically positioned to attain a competitive edge. Exploring and investing in these technologies is currently the best course of action, as the future of industrial automation is contingent on the intelligent combination of six-axis robotics and smart logistics.