Introduction

A pivotal moment in modern manufacturing is characterized by the shift from manual labor to automated processes; this development entails increased levels of productivity, precision, and efficacy. Robotic systems, specifically palletizing and assembly machines, have become indispensable in facilitating the transformation of components into finished products. Not mere machinery, these robots serve as the foundation of intelligent manufacturing, supplying the 3C sector and industries such as furniture, food, and beverage, which are all in high demand. The QJRB180-1 and QJRB30-1 robots exemplify the potential of palletizing robots, demonstrating the vast capacities and adaptability that these technological advancements afford. This article examines the critical functions performed by assembly and palletizing robots in contemporary manufacturing, emphasizing their impact on the development of the industry.

Development of Assemblage Robots

Define Assembly Robots

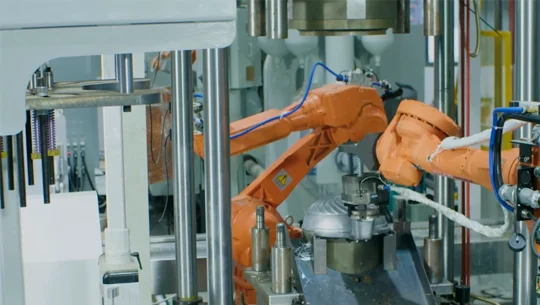

The assembly process is mechanized through the use of assembly robots, which are indispensable to manufacturing operations. Designed for duties requiring high precision and velocity, such as assembling electronic device and automobile components, among others. The incorporation of these components into manufacturing processes represents a significant advancement towards attaining exceptional levels of productivity and uniformity in the standard of goods.

Technological Progressions

The progression of assembly robots from their inception to the present is replete with noteworthy technological developments. The precision and adaptability with which the assembly robot of today can perform delicate tasks were inconceivable during the infancy of automation. Not only have advancements in robotics improved the velocity and precision of these apparatuses, but they have also broadened their scope of use, rendering them essential in numerous manufacturing industries.

Consequences of Integration

The incorporation of assembly robots into the fabric of manufacturing has extensive ramifications. In addition to the evident benefits of reduced labor expenses and increased productivity, these robots empower manufacturers to consistently uphold superior quality standards. Automating intricate assembly procedures guarantees the fabrication of products in accordance with precise specifications, thereby diminishing the potential for errors and augmenting overall operational efficacy.

Palletizing Robots in Contemporary Production

The Function of Palletizing Machines

Palletizing robots have significantly transformed the process of preparing products for transportation and storage. The process of arranging products onto pallets, which is critical for logistics and distribution, is automated by these robots. Through this action, they not only optimize processes but also enhance the velocity and precision of palletizing duties, both of which are critical for the efficient management of supply chains.

Emphasis regarding QJRB180-1 and QJRB30-1

The QJRB180-1 and QJRB30-1 robots represent the technological apex of palletizing robots. Designed for heavy-duty applications, the QJRB180-1 demonstrates its proficiency in high-speed, high-precision palletizing, picking, and packaging with its 3153mm reach and 180kg payload. In the same way, its 30kg burden and 1820mm reach make the QJRB30-1 an ideal tool for tasks that demand dexterity and accuracy. Specialized palletizing software has been installed on both robots, thereby augmenting their capabilities within intelligent manufacturing environments.

Positive Aspects of Palletizing Robots

Utilizing palletizing robotics in the manufacturing sector provides a multitude of benefits. With ease and accuracy, these robots can manipulate a wide range of objects, from small consumer commodities to large industrial components. Their capacity to function uninterrupted for extended periods of time substantially enhances the efficiency of production, whereas their accuracy in mounting merchandise optimizes the utilization of space during storage and transportation. Furthermore, the implementation of palletizing machines reduces workers’ physical strain, thereby enhancing the overall safety and comfort standards of the workplace.

A Comparative Examination: Comparing Palletizing and Assembly Robots

Identical Roles, Common Objectives

Although assembly robots and palletizing robots perform different roles in the manufacturing process, their overarching objective remains consistent: to improve productivity, accuracy, and efficiency. Assembly machines are specialized in the complex undertaking of integrating components into completed products, which necessitates exactitude and adaptability. As an alternative, palletizing robots are designed with the end-of-line process in mind, arranging products for shipment or storage with speed and precision.

Determining Between Palletizing and Assembly Robots

Several factors must be considered when deciding whether to implement an assembly robot or a palletizing robot, including the nature of the products being produced, the requirements of the manufacturing process, and the desired outcome of automation. Assembly robots are optimal for producers seeking to mechanize intricate assembly operations that demand skill and accuracy. Conversely, palletizing machines are most effectively utilized in processes that entail the swift and iterative assembly of merchandise.

Case Study: Enhancing the Production Line with Robots by Integrating Assembly and Palletizing Robots

An exemplary demonstration of the harmonious integration of assembly and palletizing robots can be observed in a cookware manufacturing assembly line. The production line employs a QJR50-1A die-casting robot to perform the preliminary operations of hot casting, deburring, stamping, and shaping. Subsequently, the completed products are palletized by a QJRB20-1 robot. This configuration exemplifies the seamless integration of diverse robot types to optimize the manufacturing process in its entirety.

Innovative Functionality and Technical Obstacles

The implementation of SCADA and MES systems in this manufacturing line signifies a significant advancement in manufacturing intelligence by facilitating remote control of robot operations and real-time monitoring of critical parameters. In addition, environmental and safety concerns are addressed through the incorporation of a smoke and particulate removal system, demonstrating the comprehensive approach to contemporary manufacturing challenges. In addition to highlighting the cost reductions and increased efficiency that result from the use of robots, this case study underscores the significance of establishing a sustainable and secure manufacturing environment.

Prospects Moving Forward in Robotic Assembly and Palletizing

Advancements in Technology on the Horizon

Potential developments in artificial intelligence, machine learning, and collaborative robotics will shape the future of assembly and palletizing robots. These technologies hold the potential to enhance the autonomy, adaptability, and collaborative efficiency of robotics in conjunction with human operators. With the increasing integration of robots into manufacturing processes, there will be a continuous stream of innovations that augment operational flexibility and productivity.

Safest Practices and Security

In the manufacturing industry, where sustainability and safety are becoming more prominent concerns, robotic automation offers feasible resolutions such as enhanced occupational safety, reduced waste, and improved energy efficiency. It is expected that the advancement of autonomous technology will revolve around the creation of systems that not only improve operational efficiency but also aid producers in their endeavors to foster environmental and social accountability.

Conclusion

In contemporary manufacturing, the transformative capacity and adaptability of assembly and palletizing machines cannot be overstated. Robotic systems are indispensable for the progression of intelligent manufacturing, as they optimize end-of-line operations such as storage and shipment while simultaneously augmenting precision and efficiency in the assembly process. The successful incorporation of these robots into the cookware production line demonstrates that a competitive advantage and operational excellence can be achieved through the strategic implementation of robotic automation on a global scale.

In order to progress towards a more sustainable, efficient, and automated future, manufacturers must first gain a comprehensive comprehension of the distinct functionalities and potential uses of assembly and palletizing robots. By capitalizing on these sophisticated autonomous solutions, manufacturers can attain unprecedented levels of efficiency, originality, and output, thereby guaranteeing their triumph in the perpetually changing realm of contemporary manufacturing.