Glass

Feel free to contact us on industrial robots and we will gladly answer any of your questions.

Robot Arms for Glass Manufacturing Industry

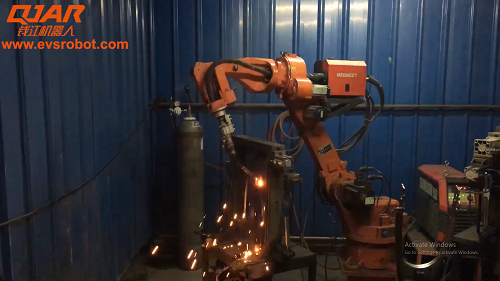

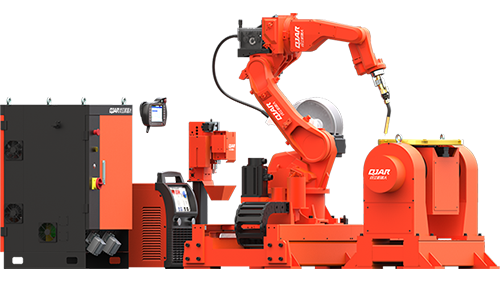

Robot automation is mainly used in material handling in glass production. They are used for heating, forming, mixing, packaging, and other complex tasks. In applications that involve glass bottles, robot arms are also used for spraying that aid in reducing stress on the glasses.

Check our website to find what industrial robot is fit for your company or contact us today and we’ll help you find the best solution for your needs!

Glass

Consistency and Accuracy

Robot arms can work continuously without affecting their performance. They are programmed to work at high-precision even with repetitive tasks.

Reduced Operating Costs

Since industrial robotic arms function with high consistency and accuracy, there will be fewer mistakes and damages. This results in reduced operating costs. Furthermore, since products now have better quality, there will also be fewer warranty costs. They also work faster, allowing manufacturing companies to get a faster return of investment (ROI).

Better Product Quality

Doing manufacturing processes manually may cause a lot of mistakes. But using robot arms for glass manufacturing, each process will be done accurately. Products will then have better quality, resulting in happier customers and better market share.