Industrial robots refer to a type of robot used exclusively as manufacturing robots. They are automated and programmable with the ability of movement along three or more axes. In a nutshell, they have robotic arms that can rotate all around. The typical work that these industrial robots are involved in include welding, painting other machinery, assembly, packaging, and labeling, among other tasks.

As of 2020, there are about 1.64 million robots in operation worldwide across various industries. The history of industrial robots dates back to 1937 when the first known form of a robot was a crane-like device that was assembled using Meccano parts and powered by a motor.

It is estimated that by the year 2030, industrial robots will have taken over 20 million jobs from people. Robotic manufacturing companies are hard at work coming up with new innovations to make this dream come true.

What is an Industrial Robot?

Source: Pixabay

An industrial robot is a programmable mechanical device with a robotic arm that can be used in the place of a human being to perform tasks that could be considered to be too risky or too repetitive, but with a much higher level of accuracy. They are intricately designed machines with moving parts, each made to perfume a unique function.

Although the cost of making an industrial robot has been high, there is a bigger benefit when using them over humans as they eliminate the need for paying staff salaries. On top of that, they do not get tired, which means they can run for days on end between maintenance seasons once in a while.

Types of Industrial Robots

As earlier mentioned, industrial robots are designed for specific roles. A robot programmed to handle welding cannot handle painting or packaging. These variations in functions help separate industrial robots into different types. As of now, industrial robots can be split into major types that include the following.

Articulated Robots

Source: Pinterest

Articulated robots are the most common of the industrial robot types. They have a factory robot arm designed in the form of a human arm connected at the joint by a twisting joint. The links in the arm are linked together through rotary joints that usually range from two to ten.

The joints provide freedom of movement, allowing the robot arms to turn in any direction without snapping. In summary, articulated robot arms have six joints making them the most flexible of all industrial robots. Hence the reason why they are the most widely used.

Pros

- It has high speeds making it ideal for industrial work that requires speed while maintaining high accuracy.

- It occupies a limited amount of floor space.

- Aligning the multiple planes is much easier compared to other types.

- They are highly flexible, thanks to their many axes that accord the arm the freedom to move in any direction.

- Articulated robotic arms can handle multiple tasks beyond the core functions that they have been designed for. This makes them the best bet for streamlining manufacturing processes.

Cons

- They are not so simple when it comes down to it. They require a dedicated robot controller.

- Their programming is very complicated and, at times, can only be run by someone who is well experienced in their operations.

- There is a lot of sophisticated kinematics involved.

- An industrial robot cost is too high, especially its manufacture.

Industrial Application

- Food packaging

- It is a robotic welding arm

- Handling of material

- Machine tending

- Steel cutting

- Forging and foundry application

- Automotive assembly

- Steel bridge manufacturing.

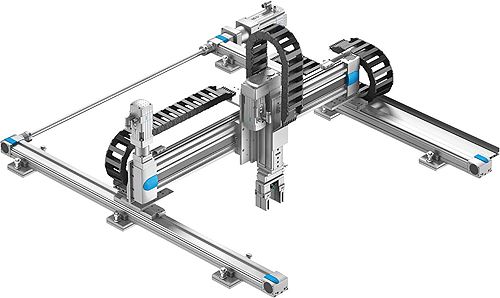

Cartesian Robots

Source: Pinterest

Cartesian robots, also called rectilinear/gantry robot, are industrial robot types that are configured rectangularly. They come with three prismatic joints that deliver the linear motion that is effected when it slides on its three perpendicular axes. At other times they are equipped with a wrist to make rotational movement possible. Cartesian robots are widely used by industrial automation manufacturers, mainly because of their simplicity and flexibility, which makes them ideal for unique tasks.

Pros

- It offers high positional accuracy.

- Its simplicity makes it much easier to operate. Anyone with the basic knowledge of how they work can set it up.

- It is much easier to program.

- It is highly customizable, making it the ideal machine when you want to switch to other tasks.

- It can handle heavy loads.

- It is much cheaper to produce one.

Cons

- Owing to its size and the range of its movements, it requires a large operational and installation area.

- As much as it is simple to operate, its assembly is too complex.

- It can only move in one direction at a time.

Industrial Application

- Loading and unloading of heavy loads.

- Pick and place robot operations.

- Assemble and sub-assembly.

- Material handling.

- Adhesive applications.

- Handling of nuclear material.

SCARA Robots

SCARA is an acronym for Selective Compliance Assembly Robot Arm, and it is an industrial robot with a work envelope shaped like a donut. A SCARA robot arm has two parallel joints that provide compliance in one place. Its rotary shifts are vertically positioned with the end effector affixed to the arm that moves horizontally.

A SCARA robot specializes in lateral movements, and for this reason, they are mostly used as an assembly robot. Compared to cylindrical and cartesian robots, SCARA robots are much faster and have an easier integration.

Pros

- They are ideal for fast and repetitive point to point movement, perfect for use as car assembly line robots.

- It has a large workspace.

- They are highly accurate.

Cons

- The SCARA robot needs a dedicated industrial robot controller.

- It is only limited to planar surfaces thanks to its design and shape.

- It is challenging to program it offline.

Industrial Application

- Assembly applications.

- Handling of semiconductor wafers.

- Biomed applications.

- Packaging and labeling.

- It is a palletizing robot arm.

- Machine loading.

Delta Robots

Delta robots are made of parallel joint linkages that are connected by a common base. Also called Parallel Link robots, they are much easier to control because each joint is positioned in relation to the end effector. This gives Delta robots a high speed in movement, making them ideal for the kind of work that involves high volume manufacturing.

Delta robots have a dome-shaped envelope, a design that reduces the weight within the arms, which ultimately is the reason for the high speed. They are mostly used for pick & place automation. They are programmed to work in perfect synchronization with other machines to make use of the speed; otherwise, it would be a disaster if something like a conveyor belt feeding materials to the robot is a fraction slower.

Pros

- They are high-speed machines. The typical Delta robot is 30% faster than a SCARA robot due to its design.

- They have high operational accuracy despite their high speeds.

- They have a high productivity output. They can process up to 3 parts per second.

- They are a safer option for repetitive and high-speed work, which can be dangerous for human beings.

Cons

- They have a lot of moving parts, which are way too complicated.

- Requires a dedicated robot controller.

Industrial Application

- Food industry.

- Pharmaceutical industry.

- Electronic industry.

- Automobile industry.

- Optical Fiber alignment.

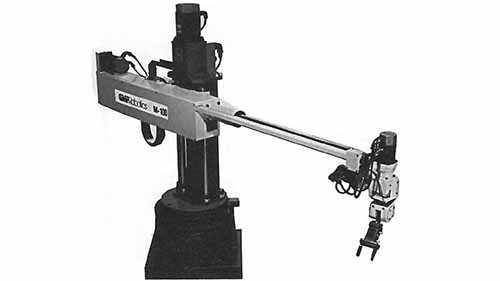

Polar Robots

Source: blog.technavio.com

Polar robots are made of a twisting joint that connects the arm with the base and two rotary joints plus a single linear joint. Due to their spherical work envelope, Polar robots are also called Spherical robots. Another unique design feature in these robots is their centrally pivoting shaft and an extendable, rotating robotic arm. It also has a gun turret configuration that covers a very large volume of space when operational.

Pros

- They have an extensive reach, with the ability to swing 360 degrees.

- They can also be able to reach for objects directly above and below them.

- They can handle a large volume of work.

- They require very little floor space.

Cons

- Although it can reach for objects above it, the vertical reach is limited, and it can not do it by itself without a controller.

- It has very low accuracy and does not do so well when it comes to repetitive tasks.

- It requires a very sophisticated control system.

- It is slowly being phased out.

Industrial Application

- Handling of glass.

- Die casting.

- Stacking and unstacking.

- Forging.

- Welding robot.

- Material handling.

- Injection molding.

Cylindrical Robots

Source: industrial-electronics.com

Cylindrical robots possess a single rotary joint at their bases and another prismatic joint connecting the inks. They have a cylindrical working space, hence their name, that comes with a pivoting shaft and an extendable robotic arm that moves by sliding vertically. This unique movement affords the robots, both vertical and horizontal movements.

The arm is also designed to allow the robot to reach tight work envelopes without any loss of speed or repeatability. Cylindrical robots are ideal for tasks that involve the picking or materials from the ground thanks to their advanced pick and place robotic arm.

Pros

- They are simple to operate and install.

- They require minimal assembly to start running.

- They can reach all around without any issue.

- They require very little floor space.

- They can handle large loads.

Cons

- They have low accuracy levels.

- They have become outdated too quickly.

Industrial Application

- Transport of LCD panels.

- Robotic assembly systems.

- Coating applications.

- Die casting.

- Foundry and forging application.

Cobots

Source: Pinterest

There is a more recent version of industrial robots in use today that is worth mentioning here. Collaborative Robots are industrial robots that can work alongside humans without any need for stringent safety barriers. They have a rounded design and are equipped with special sensors that give them the ability to always know where humans are to give them the space to assist workers.

Pros

- They are able to work side by side with human workers increasing their efficiency

- They can be repurposed easily which means they can be moved to another job quickly.

- They cost much less to build compared to the other types of robots

Cons

- They are very slow because speed has been sacrificed for human safety.

- They have a low payload capacity, again because of safety issues.

Industrial Application

- Machine tending.

- Assembly of movable parts.

- Packaging.

- Vision systems.

How Do Robotic Arms Work?

Robotic arms are designed based on the human arm, and they work almost in the same manner. How a robotic arm works depends on the task it has been designed for. In general, however, there is a specific way that all robotic arms function. They all depend on joints for movements and are equipped with other features that make this possible, sensors, for instance.

To get a better view of how they work, we must know the industrial robot parts that make up the robotic arm. They include the following:

Controllers

Source: Pinterest

Industrial robot controllers are the brains of the robot. They are the processors that carry the executable program that determines the movements that the robotic arm makes. They can either be automatically programmed or allow for manual operations by a qualified technician. In some places, they take the form of huge computer systems, and at times they are reduced to a simple joystick.

Arms

This is the part that does the actual work. It consists of three main parts: the shoulder, the elbow, and the wrist, just like humans. All these three parts are linked to each other through axes and joints controlled by the central processor, the controller. Each part has to move in relation to the other for efficiency to be attained.

End Effector

Source: Pinterest

This is the part that performs the functions of the hand. Most times, A robot end effector is made up of two claws that hold objects by closing and opening automatically. Some can spin and make maneuvering movements when holding or moving objects.

Drives

Source: Pinterest

These are the motors between the joints that control the maneuvers and the movements of the robot arms. They usually use belts that are replicas of the ones found in car engines.

Why Do You Need Robotic Arms?

Source: Pinterest

Industrial robotics companies have been on the rise in the last two decades, and as time progresses, so are the technological advancements in the robot world. Soon, we will have robots performing all the work around us. As much as they are causing disruptions as far as human labor is concerned, there is no denying that robots have made life much easier.

The following are some of the advantages of using industrial robotic arms.

Improved Worker Safety

Construction jobs are labor-intensive, and they involve a lot of heavy machinery that can pose a danger to human workers. Being exposed to harmful chemicals can also have a detrimental impact on people’s health. Industrial robotic arms have greatly reduced this risk as they can work in any condition since they are inanimate machines. They can handle repetitive work without losing focus even for a second.

Decreased Costs

Although the initial cost of acquiring a robot can be high, the long term benefits are huge. On top of scrapping the need for salaries, time offs, and other accruing benefits, robots are not prone to errors. The losses that factories have suffered due to the destruction of machines and products out of human negligence are things of the past.

Increased Productivity

What used to take days to achieve can now be attained within hours. The thing with human labor, it is prone to burn out, and rest is necessary. The only way you can keep production running for 24hrs is through shifts. Robots, on the other hand, can run for days without taking a single break. An intelligent assembly work cell can put in work that is equivalent to 4 people working at the same time.

Better Product Quality

Humans cannot replicate the accuracy and precision involved when robots are part of the production process. Robots used in manufacturing are guided by laser-sharp guidance technologies, which means every cut and measurement they make is right on the money. Articulated robots, for example, are the embodiment of accuracy in the robot world. Better accuracy translates to products with higher qualities.

Reliability

Industries that use robots in manufacturing have seen production increase exponentially. As long as they are serviced regularly, they will keep doing consistent work no matter how harsh the conditions may be. The same thing cannot be said of human workers prone to sickness and fatigue, which ultimately affects their output.

What Industries Use Industrial Robots?

Source: Pixabay

A lot of manufacturers have switched or are in the process of fully automating their production process. The reasons for this are many, but the main one is that robots are reliable, reduce the cost of paying salaries, and save money that can be redirected to other things. The following are some of the industries that utilize robotic arm applications in their manufacturing processes.

Automotive Industry

Robotics in automotive manufacturing were among the very first to be adopted as far as industrial robotics go. As of now, you will not find any car maker that does not employ a car manufacturing robots for over 75% of its production. The automotive industry accounts for about 30% of the total industrial robotic arm installations. The most commonly used robot by car manufacturers is the ABB IRB 6640 that is good for welding car frames into place.

Aerospace industry

Just like the automotive industry, the making of planes requires a lot of robot power. The demand for air travel is increasing the world over, and to meet this demand, there is a need to manufacture more airplanes faster than before. Industrial robots are the answer to this need as they are faster and can be programmed to handle any kind of task. Applications like motor parts painting, sealing, drilling, and welding are some of the things that are handled by automated machines.

Electronics Industry

Electronics are part of our lives, and we cannot do without them. Their manufacture involves a lot of components whose assembly can be easily lost to humans. Industrial robots are now being heavily used in the manufacture of electronics as they are more adept at dealing with tiny and sensitive parts of electric appliances. The use of cleanroom robots, for instance, has greatly improved the quality of electronics as they prevent dust from ever coming into contact with the internal parts during assembly.

Food Industry

Food packaging is now handled exclusively by robots. In some places, it is even part of the requirements to employ the services of robots in a sensitive job that is the packaging and warehousing. The advantages of using robots in food processing is that there is less chance of contamination since robots are precise and fast. Putting food into the right portions and sizes has also become the hallmark of robotic food processing.

Medical and Pharmaceutical Industry

The sorting, bottling, dispensing, and inspection of medications is now a preserve of industrial robots. Robots have now been programmed to measure the exact amount of drugs on the last milligram. Robots in the medical and pharmaceutical industry have made it easier to handle drugs in a better way that avoids excessive wastage and contamination.

Delicate medical devices like surgical tools are now manufactured to the exact sizes as needed using medical robots that are changing the world. When medical tools are compromised, it makes it harder for doctors to treat their patients properly.

How Much Does A Robotic Arm Cost?

Source: Pixabay

Robots used to cost a lot more in the past than they do right now. Mass production has made it possible for the prices to come down a little, but they are still on the higher end of the budget. In the present market, the average industrial robot price is about $25,000, but it can rise to over $400,000 depending on the model and the size.

A robotic arm price also tends to go higher as you add more peripherals and extra features. Application-specific additions, like collision sensors and safety cages, which are a necessity, can double the initial price of the whole machine.

As an interested buyer, you can either go for a brand new robot or a cheap industrial robot arm that has been used before. One advantage of going for a second-hand robot is that you save on the cost, although you will experience some little mishaps along the way.

The Best Programmable Robotic Arms of 2020

As the use of robotic arms across all industries rises, models are being created to handle application-specific tasks for various manufacturers. The following are the best programmable industrial robotic arms of 2020.

DOBOT Magician Educational Programming Robot

Source: Pinterest

This is a robotic arm that is designed for multi-tasking. It can handle 3D printing, laser engraving, pick and place, drawing, and writing machines. It is equipped with over 20 coding languages, while at the same time, it is simple enough to be used by a beginner level individual.

LewanSoul LeArm 6DOF Full Metal Robotic Arm

Source: Amazon

This is an arm that is powered by a servo to effect movement flexibly. It has a metal claw that is strong enough to handle heavy loads in any direction. Control of the robot can be done wirelessly and, at the same time, can be controlled through a smartphone.

QJRB800-1 Robot Arm

This is a robotic arm created by EVS that has a maximum payload of about 1700 pounds. The whole robot itself with the other parts combined is about 5600 pounds which gives a very stable foundation for any heavy lifting task common in most manufacturing industries.

Owi Robotic Arm Edge

Source: Pinterest

This is a robotic arm equipped with five joints controlled by a wired-5 switch controller that can be operated remotely. D batteries can power the robot at the same time it can be powered by AC power. It has a base rotation of 270° and has an extended life on the gearbox.

How To Choose Industrial Robotic Arms

Source: Pinterest

When it comes to choosing a robot arm, there are things you must consider first.

Application

Just because it is a robotic arm does not necessarily mean that you can use it to open your beer, each robotic arm is designed for a specific application. An arm designed for painting cannot be used as a polishing arm or vice-versa. Unless the robotic arm is a multi-purpose one, then you are stuck with one function robotic arm.

Payload

Payload refers to the maximum amount of load that the robotic arm can handle. If you are dealing with a heavier load like industrial packaging, then you will need to go for a big robot arm that can handle heavier loads with a simple pick and place automation.

Degree of Freedom

The movement a robotic arm can maneuver depends on the number of axes. The more the number of axes, the more flexible the arm will be in terms of movement. Bigger robotic arms require more axes as it takes more effort for them to turn.

Speed

If you are dealing with repetitive tasks, then you will be best served with a high-speed robot arm that is as fast as possible, an articulated robot is an example of a fast robot that is suitable for such a task. Some robotic arms come with the options that allow the controller to adjust the speed.

Cost

You can only get what you can afford. If you’re dealing with high volume work like manufacturing, you will need more than one robotic arms, which will cost you a lot. If all you are looking for is a simple contraption for home use, then a simple low-cost robot arm is what you should be going for.

Conclusion

Industrial robot technology is becoming indispensable as time goes by. The manufacturing industry is as good as done with human labor already as we speak. The little left of human labor is reduced to maintenance and the controlling of these robots when the need arises. Someday, in the future, robots will be the standard feature in all industries around the world.