Introduction

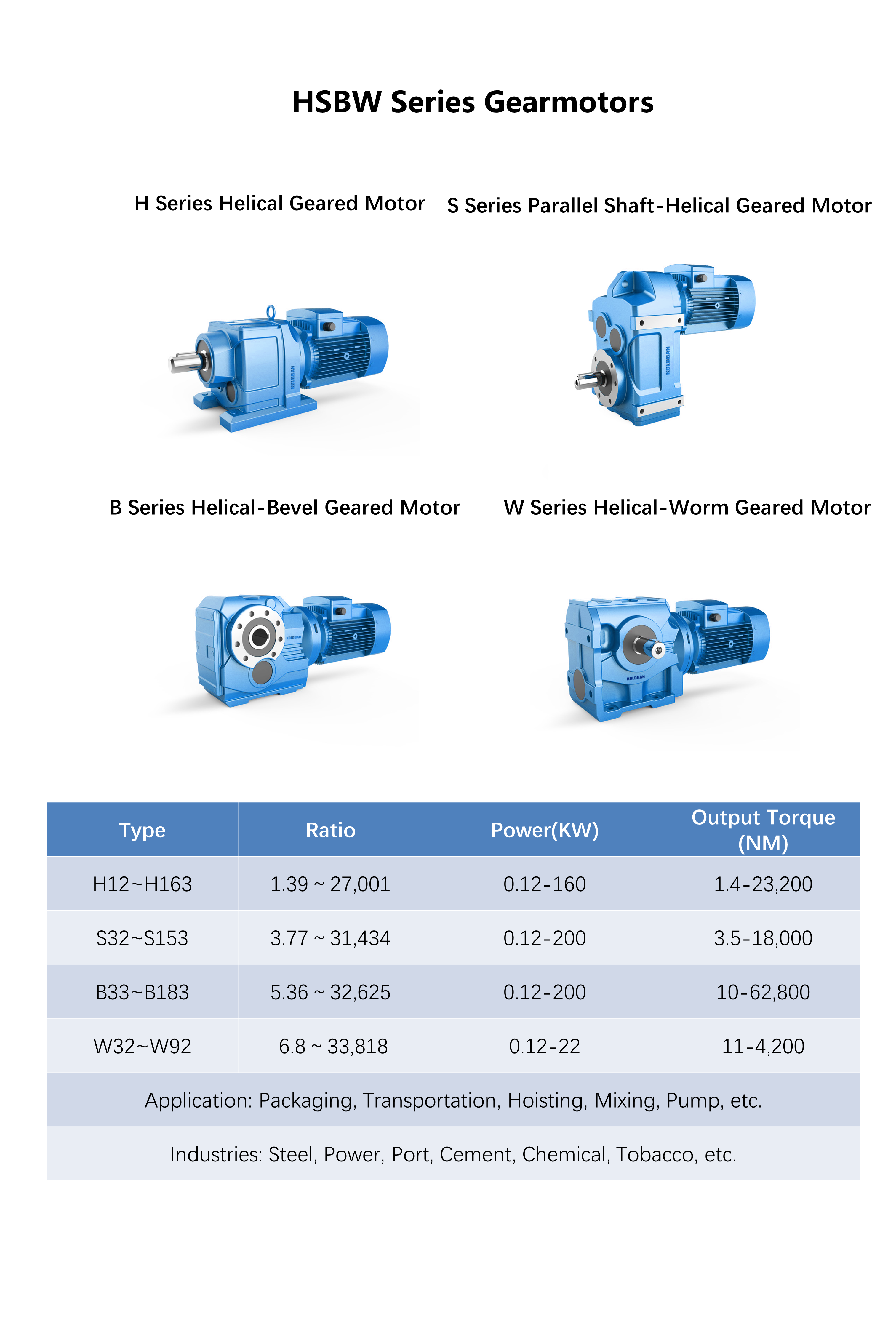

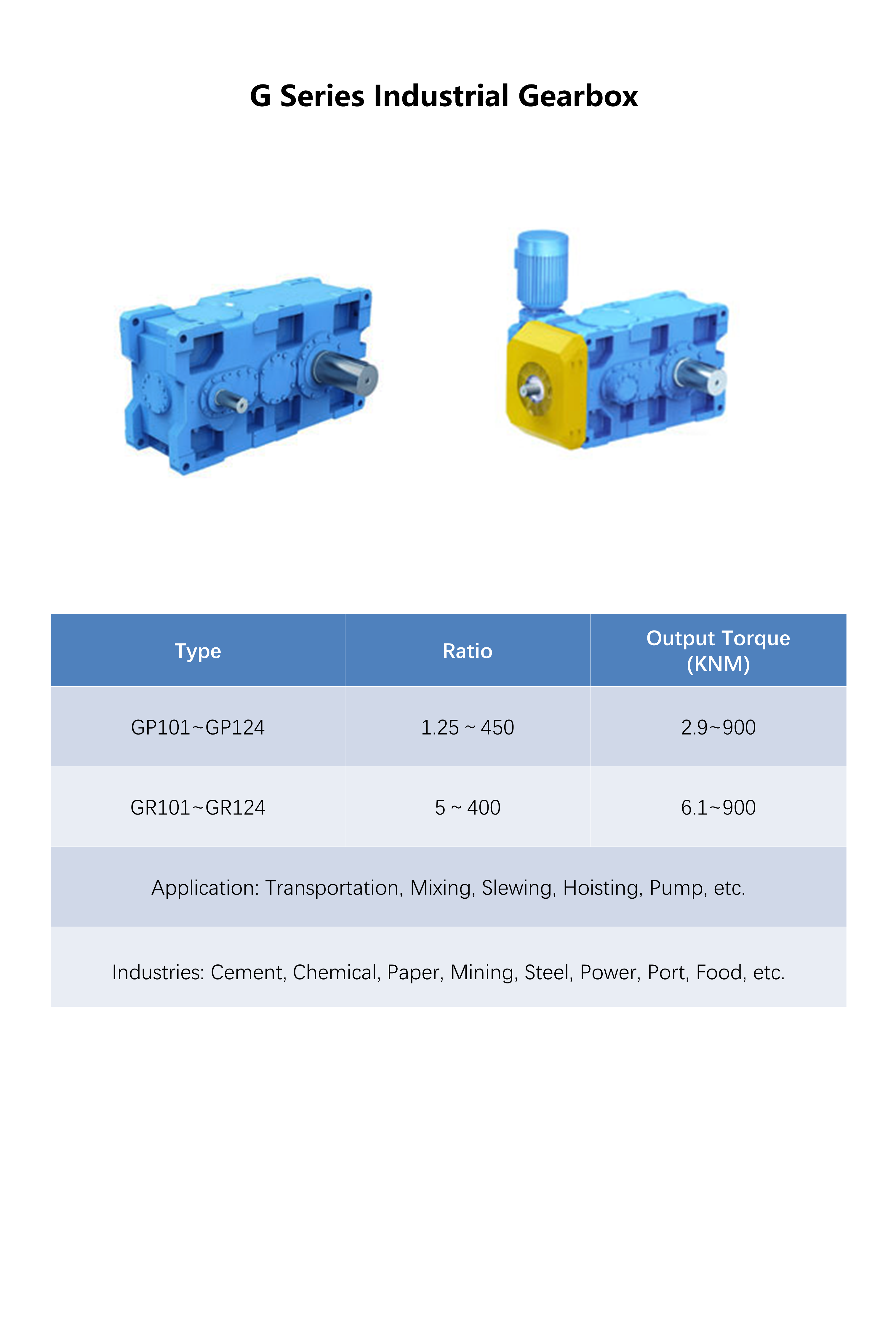

Two unsung heroes play a major role in the complex dance of power transfer and control found in industrial machinery: the gearbox and the gear motor. These constituents provide the fundamental basis of automation, exerting a pivotal influence on the operational efficacy and efficiency of intricate systems. The potential contained within these systems is enormous, given the technological specifications of the G Series Industrial Gearbox, which offers a torque range of 2.9-900 KNM and a ratio ranging from 1.25 to 450, and the adaptable HSBW Series Gearmotors, which serve applications across industries like cement, chemical, and paper. This essay will cover the mechanical subtleties, design concepts, range of applications, and innovation-driven culture that maintain these gear systems at the forefront of industrial development.

The Workings of Gearboxes and Gear Motors

Comprehending Gear Motors

Fundamentally, a gear motor combines a motor with a gearbox to balance rotational speed and torque for certain industrial applications. This integration is embodied in the HSBW Series Gearmotors, which demonstrate a range of applications from packing to transportation. These gear motors have torque outputs ranging from 1.4 NM to 23,200 NM and power capacities ranging from 0.12 KW to 200 KW, providing the flexibility and strength required for applications requiring longevity and accuracy.

The Complexity of Gearboxes

By regulating the motor’s speed and torque to the specifications needed for the application, a gearbox serves as a regulatory agency. It is essential to automation and production because it transforms the bare motor power into precisely calibrated forces and motions. This potential is best shown by the G Series Industrial Gearbox, which has an amazing output torque capability that makes it appropriate for heavy-duty activities in steel and mining sectors. This series’ wide range of gear ratios makes it possible to tailor these gearboxes to meet certain operating requirements.

Creation and Production of Gear Systems

Creative Design Methods

It takes a thorough grasp of mechanical engineering concepts to design gear motors and gearboxes, which is a challenging task. These systems can now handle a wide range of industrial applications and are more efficient, small, and competent because to advancements in design methodologies. These creative designs have resulted in the G Series and HSBW Series that are offered; they enable versatility in installation by allowing for ground or inverted locations, and they cover a wide range of ratios and power levels to meet various operating demands.

Components and Production Methods

The quality and endurance of gear systems are largely dependent on the materials and manufacturing procedures employed in their development. Products like the G Series Gearboxes and HSBW Series Gearmotors are made to be strong, dependable, and able to operate at high performance levels for extended periods of time—even in demanding circumstances—by using high-strength alloys and precision manufacturing techniques.

Utilization and Effectiveness

Industrial Uses for Gear Systems

In today’s business, gearboxes and gear motors are widely used in anything from basic automated systems to very complex mechanized operations. They are critical to operations requiring precise motion control, such robotic arms used in production lines. With its 2001mm reach and 10kg payload, the QJR10-2000 robotic arm is a perfect example of a machine where gear systems are essential to maintaining accuracy and effectiveness in a variety of uses, such as sorting, welding, and assembling.

Increasing Effectiveness and Output

The addition of gear motors and gearboxes greatly increases the efficiency and performance of machines. They are the factors that determine torque control, speed, and precision in an operation. These gear systems improve the capabilities of machines and raise the general productivity of industrial activities. Two examples are the HSBW Series Gearmotors, which are renowned for their high-speed operation, and the G Series Industrial Gearbox, which can manage a broad torque range.

Innovation and Case Studies

Analysis of Case Studies

Several case studies demonstrate the concrete advantages that gearboxes and gear motors provide in a variety of industries. An automated packing line, for example, saw a 40% improvement in production output when a gear motor from the HSBW Series was implemented. This illustrates the rapid impact of integrating sophisticated gear systems into industrial processes.

Prospects for the Design of Gear Systems

It is obvious that the development of gearboxes and gear motors will continue as we move to the future. These systems might be further improved by emerging technologies like IoT and AI, which could make them even more intelligent, responsive, and effective. Automation and machinery are expected to go much farther as long as gear system design remains innovative.

Conclusion

The development of automated systems and their seamless functioning depend on the gearbox and gear motor, which are foundational pieces of industrial machinery. The need for these components only grows as businesses expand and change, and their ability to advance productivity and efficiency is more important than ever. It is not only reasonable but also necessary for the future of industrial automation that they continue to improve.

It is essential for anyone working in the industrial sectors to understand the potential and significance of gear motors and gearboxes. To boost performance, industry experts should aim to have a thorough understanding of these elements and think about integrating them into current systems. Working with gear system manufacturers and specialists will guarantee that you have access to the best and most cutting-edge solutions for your operational requirements, enabling you to fully use these formidable instruments in the age of intelligent automation.

Arabic

Arabic Bulgarian

Bulgarian Czech

Czech Dutch

Dutch English

English Finnish

Finnish French

French Georgian

Georgian German

German Greek

Greek Hungarian

Hungarian Italian

Italian Japanese

Japanese Korean

Korean Lithuanian

Lithuanian Myanmar (Burmese)

Myanmar (Burmese) Persian

Persian Polish

Polish Portuguese

Portuguese Romanian

Romanian Russian

Russian Serbian

Serbian Slovak

Slovak Spanish

Spanish Swedish

Swedish Thai

Thai Turkish

Turkish Ukrainian

Ukrainian Vietnamese

Vietnamese