A robotic arm is the most important part of a robot as it is the one that handles the actual work. It is painting, palletizing, picking, and placing, it is the part that actually does the work, just like the human arm. Most robotic arms have axes that connect the joints for flexibility of movement, they need to bend and extend at will depending on the work they are involved in.

Parts of a Robotic Arm

A robotic arm is made up of various parts that work together to make work easy. These parts are manufactured separately then assembled together to complete an industrial robotic arm. The following are the main parts of a robotic arm.

A Controller

Source: Pinterest

This is the brain of the whole structure. It is usually in the form of a motherboard, but a smaller one, upon which the program responsible for making the robotic arm to function is written in. It is the most sophisticated part of the robot and it is usually encased to protect it from external damage as it is delicate and expensive.

Grippers

Source: Pinterest

Grippers are fingers. They are extendable projections at the end of the robotic arm that usually do the grabbing of items during manufacture, picking and placing of loads, and handling packaging. Most are electrically set up and are usually in a set of ‘3 fingers’ for a better grip. Grippers have to be strong since they bear most of the brunt that comes with handling heavy payloads.

Joints

Source: Pinterest

Without joints, there would be no movement of robotic arms other than rotating about their envelopes. Joints give the arm the ability to bend and stretch out and rotate about the axis. Without these movements, a robotic arm would not be able to handle even the simplest tasks you can think of.

Motors

Source: Pinterest

While controllers act as the brain, the motors are the engines that bring about all the movements a robotic arm makes. Motors are electrical devices that control the movement, the speed, and the direction that the robotic arm makes based on a set of instructions from the controller. There are four types of robotic arm motors: AC/DC motors, Servo motors, Stepper motors, and Linear motors.

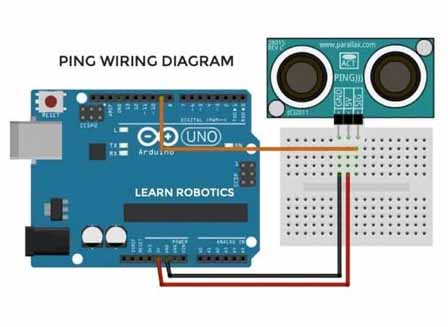

Sensors

Source: Pinterest

Robotic sensors are the eyes and ears of the robotic arms, they are what the arm uses to judge distance and detest items that are supposed to be grabbed. Sensors are highly advanced and can know when there is an obstacle in front of them with the ability to pick out what they are supposed to with precision.

How a Robotic Arm is Made

How a Robotic Arm is Made video presentation

Owing to how sophisticated robotic arms are, there is a high level of designing that goes into making them. The following are some of the steps it takes to make a robotic arm from scratch into a fully functioning machine.

Step 1: Creating the Program

Being the brain, the program that will run the robotic arm is the first thing to be made. The eventual size of the robotic arm will be determined by how advanced the program is and how much it can handle.

Step 2: Installing the Motor

After the program is good to go, the engine is the next item to be made. The motors are linked to the program and tests are run to see if it is responding to commands fed to it by the controller. Once that is done, you already have the heart and the brain of the robotic arm.

Step 3: Assembling the Base

The base that forms the foundation of the robotic arm is handled in the third stage. This is the part that will rest on the floor or the assembly table. It has to be heavy to counter the weight of the extended arm so that it does not topple over.

Step 4: Putting the Joints and Shoulder together

The movable parts of the arm are assembled in the fourth stage. This is an important step because it is where the full reach and the maximum turn of the arm are determined. Depending on the size of the base, the joints could range from 2 to 10, with a 6-axis robotic arm being the most common. The more the joints the bigger the robotic arm.

Step 5: Adding the Grippers

The parts that will be handling the delicate parts of work like welding, cutting, lifting etc are called the grippers. These are attached at the end of the robotic arm to form what resembles human fingers.

Step 6: The Wiring

Being an electrical contraption, all these parts are connected to each other by a network of electrical wires that transfer power to each component. The wiring has to be done in such a way that does not hinder the free movement joints.

Conclusion

Making a robotic arm is not a walk in the park, it is a complicated job that requires robot manufacturers to employ the services of several people for the end product to be able to work as expected. The cost of making one is quite high and this is why robotic arms can cost exorbitant prices. But when you consider the long term benefits, it is totally worth it.