In this article, we’d like to show you how easy it is to use a welding robot, including robotic welding programming, touch sensing, seam tracking(arc tracking/laser tracking), maintenance, and other basic instructions.

When it comes to the robot, especially a welding robot, factory owners or workers often thought it is a high-tech machine that they can’t deal with. But it is not the case actually, a welding robot is just a machine that does what you told it, all you need to do is teach it. There is a step-by-step instruction of how to use a welding robot from scratch as follow:

1. The first step is to choose a suitable robot arm and a welding power source.

Since welding robot suppliers often will provide you a complete robotic welding package with a robot arm, welding power source, wire feeder, and all the peripherals, you just pick the best-matched package.

Selection criteria:

1. Based on your working piece dimension and the position to be welded, you can decide the robot arm length. Usually, a welding robot has 1.4 meters or 2 meters of arm length.

2. Based on your requirements of the welding process, you can choose the welding power source and the shield gas. You can choose MEEGMEET, AOTAI, ESAB, Fronius, Lorch, or any other power source your supplier recommended. You can choose MIG/MAG/TIG welding, pulse/swing, etc.

2. Whether and how to choose a welding positioner?

After choosing the welding robot arm and the power source, you need to design the welding fixtures or jigs or clamping system. There is another point you need to pay attention to, whether and how to choose a welding positioner.

If the working piece is very big or the positions need to be welded are complicated, you may need a welding positioner to get a perfect position and best angle for welding. There are many robot positioners to choose from:

3. How to program a welding robot?

Maybe programming is the most cared matter when you want to use a welding robot. You may think it is difficult but actually it is relatively easy after basic training. The most common method is using a teach pendant to teach the robot where to go and where to start the arc and end the arc. Later we will upgrade detailed instructions on how to do the programming.

4. The function you can use in a robotic welding package.

Other than the basic function of a manual welding power source like single/double pulse, there are more functions you can choose from a welding robot package to get a wanted welding effect. You can use functions like: swing arc, seam tracking(arc tracking and laser tracking), touch sensing, external axis synergy, etc.

Arc Tracking: adding an arc sensor can realize arc tracking. The arc sensor is an instrument used to compensate for the robot path for a weld bead that is slightly offset from the teaching point in the gas shielded welding process. Relative to the robot tool coordinate system, path compensation can be performed in the up and down and left and right directions, but this function can only be realized when the Z-pendulum is used and can be used in straight and circular paths.

Laser Tracking: Using intelligent real-time and non-contact tracking technology, laser sensors can lead and control the torch positioning correctly through measuring the seam deviation, which can avoid bad products’ producing and improve the quantity and quality of products.

Swing Arc: Swing arc is a method in which the welding torch faces the welding direction and periodically swings from side to side at a specific angle during arc welding, thereby increasing the width of the welding bead to improve the welding strength.

Touch Sensing: because of the tolerance of some working piece, there will be a slight offset from the actually needed welding path and the programmed path, touch sensing function can modify this slight offset to make sure we get the perfect welding effect. The touch sensing function can modify displacement, rotation, etc.

External Axis Synergy: a welding robot system can control the robot and also the positioner and make them synergy on a real-time level. That means the robot axis, welding gun position, and angles, positioner gesture can move at the same time to get the extremely perfect position for some complicated working piece.

Remote Mode: Using remote mode can allow the workers to operate a robotic welding cell at a safer distance and get away from the toxic gas.maintenance of a welding robot kit.

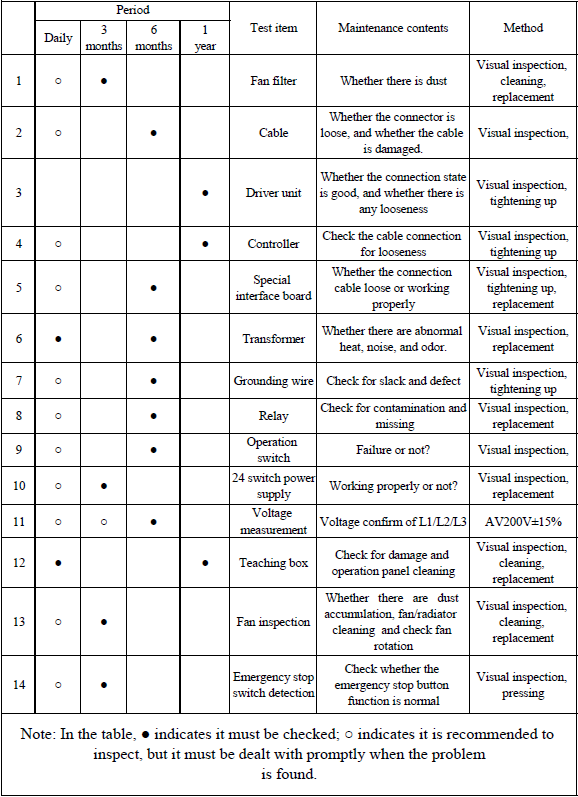

5. Maintenance Of A Welding Robot.

See the time table of a welding robot maintenance bellow:

Last words: If you have any questions about welding robot, please feel free to reach out.