Introduction

Advancements in welding technology have resulted in significant breakthroughs that have revolutionized a variety of industries. A game-changer among these advancements, laser welding robots are characterized by their unparalleled precision and efficiency. Due to the integration of robot tracks, which further enhances their capabilities, these robots are indispensable in contemporary manufacturing. This article explores the revolutionary potential of laser welding robots and robot tracks, emphasizing their advantages, technical details, and practical uses.

Automated Laser Welding Systems’ Ascent

In place of conventional welding techniques, laser welding technology has been implemented. Laser welding robots can achieve precision and accuracy levels that are superior to those of manual welding due to the use of concentrated laser beams. These are among the numerous benefits of this technology:

Accuracy and Precision: Laser welding robots are capable of consistently producing exceptional welds by precisely concentrating on small regions.

Production Efficiency and Speed: The high speed of these robots significantly reduces production time and increases throughput.

Versatility of Materials: Laser welding is capable of joining a variety of materials, including stainless steel, carbon steel, copper, and aluminum.

A laser welding robot with a 1.4M reaching distance and a 6KG payload is the QJR6-1400H, a well-known example. It possesses six axes of motion. This robotic device serves as an exemplary illustration of the cutting-edge capabilities and attributes that render laser welding robots an indispensable asset in a variety of industry sectors.

A Comprehensive Synopsis of the QJR6-1400H Welding Robot

The QJR6-1400H welding robot is distinguished from its rivals by a number of features and advantages. Important characteristics consist of:

Multiterm Exclusive Patents: By combining several exclusive patents, the QJR6-1400H offers a more affordable solution than comparable products on the market.

Joint Gear Grip Adjustment: This feature improves the robot’s precision by enabling precise control and fast dynamic response.

Hollow Joint Support Structure: More flexibility and rigidity make it possible to perform more intricate welding operations.

Noise Reduction Structure: The QJR6-1400H’s noise reduction structure ensures a gentle running sound while operating quietly.

Repeat Positioning Accuracy: This robot guarantees accurate and consistent welds with a repeat positioning accuracy of ±0.08mm.

Armspan: The robot’s 1456mm armspan enables it to access a wide scope of applications.

Because it is capable of accommodating a diverse array of materials, such as copper, aluminum, stainless steel, and carbon steel, the QJR6-1400H is versatile in industrial applications.

Robot Tracks’ Function in Laser Welding

Robotic tracks are essential for increasing the effectiveness and mobility of laser welding robots. Robots’ operational flexibility and productivity are increased by these tracks, which enable them to move along predefined paths. Among the main advantages of incorporating robot tracks are:

Increased Range of Motion: Robot tracks allow laser welding robots to cover a greater area without having to reposition themselves because they increase their operational range.

Improved Stability and Accuracy: The tracks make sure the robots move steadily and precisely, preserving the level of precision needed to produce welds with excellent quality.

Customization Options: Robot tracks can be made to match certain specifications, like length and rated load, so they will work flawlessly in a variety of industrial environments.

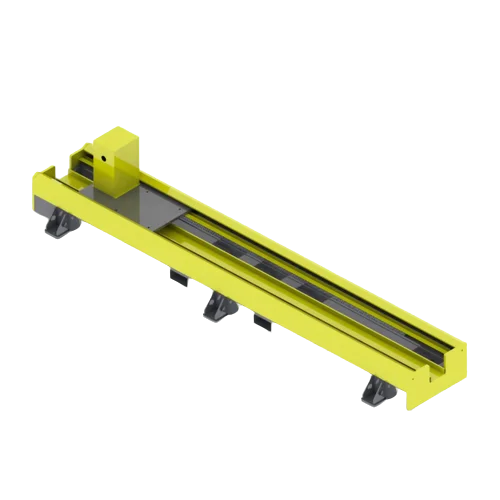

One great example of a track system made to work with laser welding robots is the EVS Robot track. It is appropriate for a range of industrial applications due to its features and technical specifications.

Technical Details of the Robot Track for EVS

The EVS Robot track is designed to give laser welding robots strong support and accurate mobility. Among its technical specifications are:

Walking Mode: Light-duty Single-Axis Ground-Mounted Robot Servo Walking Rail

Model: Z-L-XX-GS-SXW

Applications: Fit for machining, painting, gluing, cutting, and handling

Length: 4000 mm standard, with extended standard lengths available upon request in 1000, 2000, and 4000 mm.

Ground mounting is the mounting technique.

The overall dimensions are L mm × 910 mm × 750 mm, with L depending on the motor being used.

Semi-enclosed sheet metal for protection

Lubricating System: AC220V oil pump voltage for self-lubrication

Chain of Drag Position of Mounting: Center

The EVS Robot track is a dependable option for preserving accuracy in a range of industrial applications because it guarantees repeat positioning accuracy of ±0.10mm for payloads under 1000 kg and ±0.15mm for payloads between 1000 kg and 3000 kg.

Applications in the Real World and Case Studies

Robot track and laser welding robots have found use in many different industries, greatly increasing output and quality. Among the noteworthy instances are:

Automotive Industry: To ensure excellent precision and strength in the welds, car bodies are assembled by laser welding robots. These robots can weld separate sections together without assistance from humans by moving along the production line on robot tracks.

Aerospace Industry: Accuracy in laser welding is crucial because even minute imperfections can have disastrous consequences when producing aerospace parts. Robot tracks enable welding robots to move across large aircraft components with ease.

Manufacturing Industry: To weld complex parts, shorten production times, and boost output, robot tracks and laser welding robots are used in general manufacturing.

Case Studiese

Automobile Assembly Line: To automate the welding process, an automotive manufacturer combined laser welding robots with EVS Robot tracks. The efficiency and accuracy of the combined system were demonstrated by the 30% increase in production speed and 25% decrease in defects that followed this integration.

Aerospace Component Manufacturing: To weld large aircraft sections, an aerospace company used laser welding robots on a robot track. The company was able to adjust the system to different production requirements by varying the load capacity and track length, which resulted in a 20% increase in overall production efficiency.

Prospects for Automation and Robotic Welding in the Future

Numerous new trends are expected to have a significant impact on the future of robotic welding and automation as these fields continue to develop:

Machine Learning and Intelligent Automation: The integration of AI and ML into laser welding robots will improve their capacity to optimize processes in real time and adapt to various welding tasks.

By infusing human flexibility with robotic precision, collaborative robots, or Cobots, operate in conjunction with human operators. Laser welding cobots may become increasingly prevalent in a variety of industries as a consequence of forthcoming developments.

Improved Robot tracks: Upcoming robot tracks are probably going to have more sophisticated construction and materials, providing even more stability, precision, and personalization possibilities.

Even with the encouraging developments, there are still issues like expensive initial costs and the requirement for specialized knowledge to run and maintain these systems. Ongoing innovation and educational initiatives, however, can lessen these difficulties.

In summary

With previously unheard-of levels of precision, efficiency, and adaptability, laser welding robots and robot track are revolutionizing industries. The cutting-edge technologies propelling this shift are best represented by the QJR6-1400H welding robot and the EVS Robot track. We can anticipate notable increases in productivity and quality as industries continue to use these cutting-edge systems, opening the door to a new era in automation and manufacturing.Length of arm: The robot can access a wide range of areas thanks to its 1456mm armspan, which makes it suitable for a variety of applications.

The QJR6-1400H is versatile enough to handle a wide range of materials, including copper, aluminum, stainless steel, and carbon steel, making it suitable for a multitude of industrial uses.