In today’s frenetic logistics environment, palletizing robots are indispensable because they make smart logistics systems function more successfully and efficiently. These advanced robotic systems have fundamentally transformed the logistics industry by automating repetitive, high-volume tasks, increasing operational speed, accuracy, and efficiency. The collaborative palletizing robots from EVS, available in 6kg and 12kg payload models, are ideal for increasing the productivity of distribution centers and warehouses. These robots increase productivity and remove errors in smart logistics situations.

Palletizing robots’ Function in Intelligent Logistics

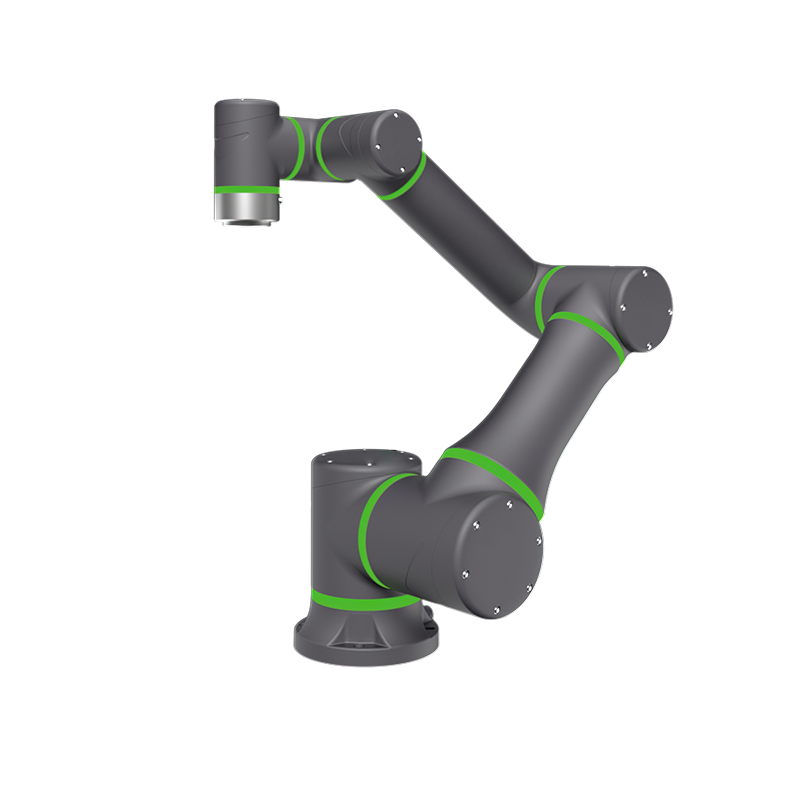

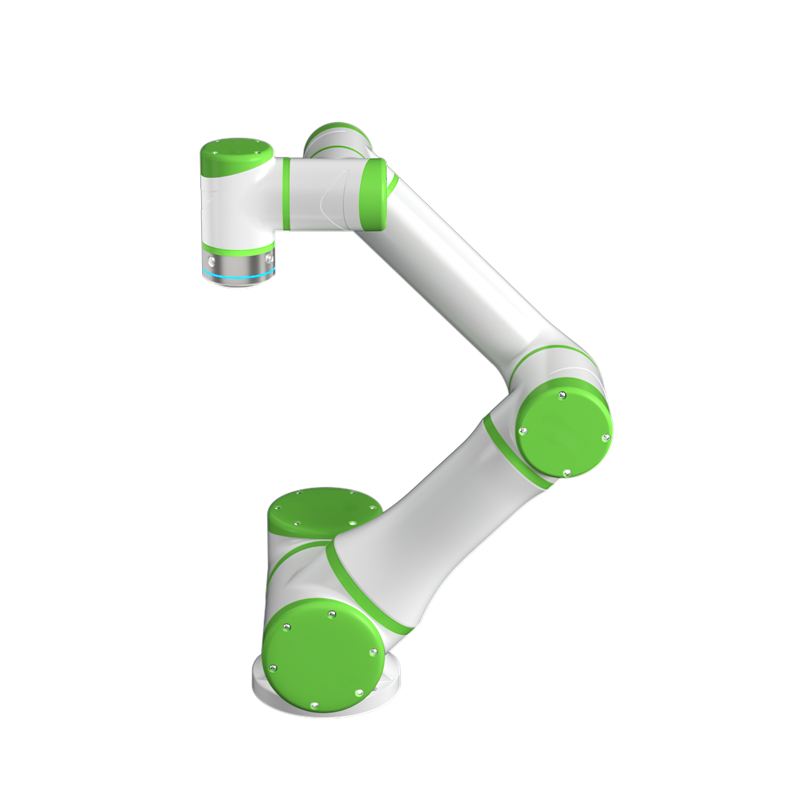

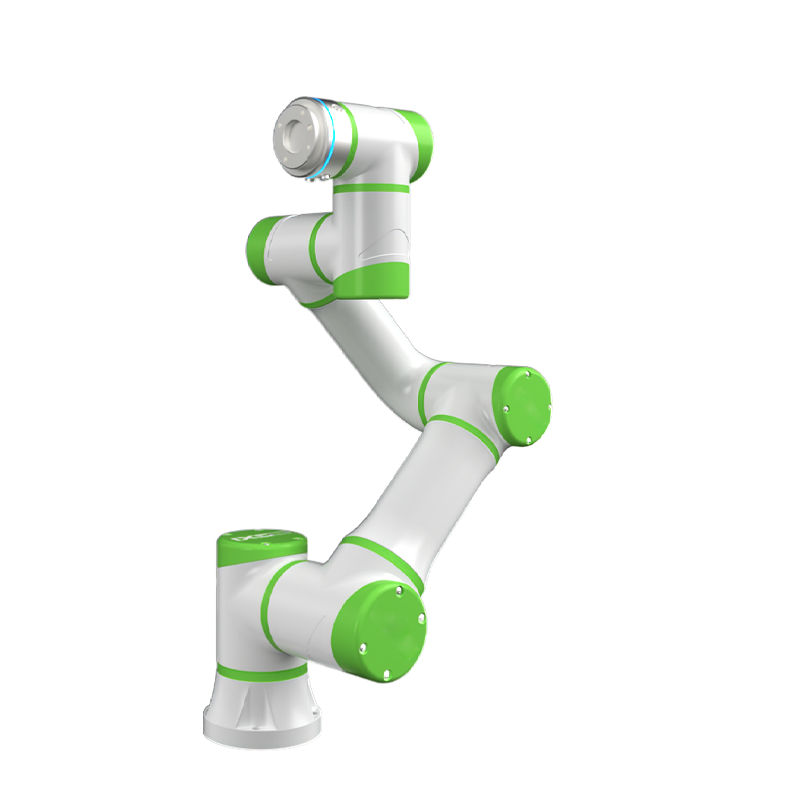

Robots that palletize are made to do repetitive jobs including stacking, arranging, and moving items on pallets. Palletizing robots are essential in smart logistics because they decrease human error and boost throughput, two factors that are critical in this industry. Smaller logistics companies can benefit from the superior handling of lightweight items by EVS’s 6kg Payload Six-Axis Collaborative Robot. Every shipment may be efficiently sorted for transportation with the help of this robot, which can rapidly and properly place products on pallets.

Palletizing robots increase efficiency by allowing robots to complete activities that would take humans far longer to complete. The use of automation in smart logistics is significant. Palletizing robots are particularly useful in high-demand settings like manufacturing plants and distribution hubs since they can operate nonstop without becoming tired. To speed up and improve the effectiveness of handling goods, palletizing robots are utilized in smart logistics systems.

How Automated Palletizing Increases Productivity

An important benefit of using palletizing robots in smart logistics is the notable increase in operational efficiency. These robots cut down on the amount of time required to do processes like sorting, packaging, and stacking by automating these jobs. With a 1300mm reach, the 12kg Payload Six-Axis Collaborative Robot from EVS can handle bigger loads and more voluminous objects in warehouse settings. By ensuring that commodities are handled effectively, this approach facilitates more seamless transfers across the logistics chain. Robots that automate the palletizing process improve accuracy.

Robots that Palletize: Their Effect on Labor Efficiency

Palletizing robots are a terrific method to increase worker productivity and safety while also cutting labor costs in smart logistics operations. These robots can do tasks that often need a large team. Palletizing robots free for human laborers to focus on more complex and lucrative tasks by automating physically demanding and repetitive tasks like lifting and stacking. This also lessens the possibility of injury from physical lifting.

The 6kg and 12kg Payload Palletizing robots from EVS are designed to work together with humans in smart logistics settings, allowing them to operate securely alongside them. Because of their sophisticated sensors and safety features, these robots are perfect for work areas where people and robots coexist. Businesses may boost productivity without adding more workers by incorporating palletizing robots to improve operational efficiency, reduce downtime, and increase production.

In Smart logistics, Scalability and Adaptability

Palletizing robots provide the adaptability required to meet shifting demands, which is a crucial aspect of smart logistics. Collaborative robots from EVS, such the 6 kg and 12 kg Payload models, may be used for a range of palletizing jobs and are appropriate for operations with varying capacities. Because these robots are easily programmable to handle a variety of product kinds, firms may modify their workflows without having to make large changes to them. To be competitive, smart logistics must be adaptable to changing conditions.

Palletizing robots’ Future in Smart logistics

In smart logistics, palletizing robots appear to have a bright future as more businesses seek to automation to fulfill the increasing demand. The more complicated supply chains get, the more advanced automation solutions, such palletizing robots, are needed. The EVS collaborative palletizing robots are designed to endure this extra complexity, facilitating seamless system integration while providing the flexibility needed to overcome novel challenges.

With developments in artificial intelligence and machine learning, palletizing robots will become more intelligent and capable of optimizing their own operations. These robots will be able to adjust their actions in response to real-time data, which will boost output and reduce running costs. Palletizing robots will continue to be crucial in shaping the future of smart logistics, driving more automation, accuracy, and productivity in the industry.

In summary

To sum up, palletizing robots are automating critical tasks like sorting, stacking, and shipping products, which is transforming smart logistics. The 6kg and 12kg Payload of EVS For companies trying to optimize their shipping processes, collaborative palletizing robots are the ideal answer. Palletizing robots are crucial in today’s logistics environment due to their capacity to increase scalability, accuracy, and efficiency. In an increasingly automated environment, businesses may maintain their competitiveness, cut expenses, and boost productivity by incorporating these robots into their operations.