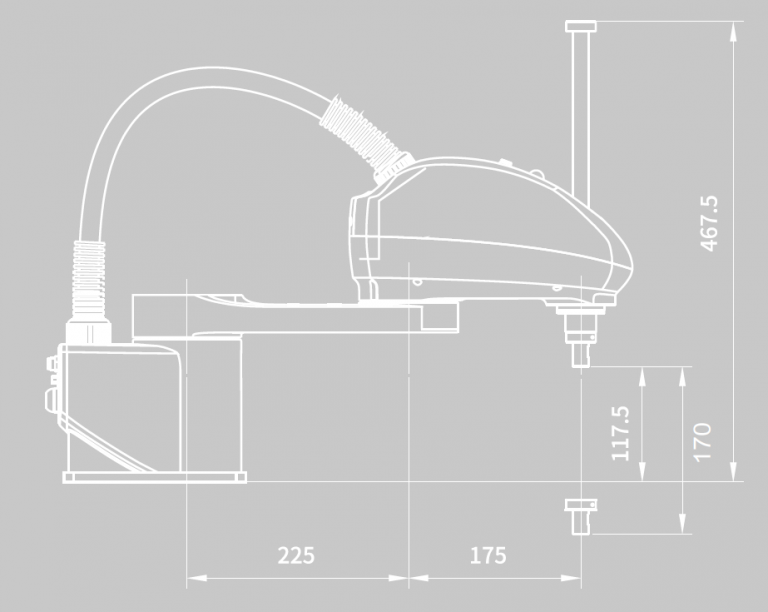

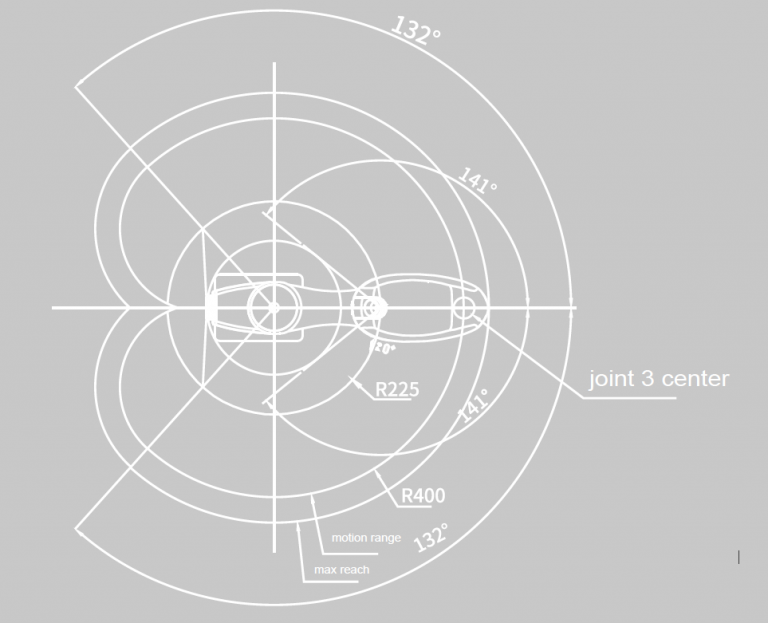

SCARA robots are becoming essential instruments for increasing accuracy, speed, and efficiency in the quickly changing production world of today. Simplifying intricate production operations, the 4-axis SCARA robot EVS SCR003-400 model is a prime example of automation’s power. Because of its 400mm reach and 3kg payload, SCARA robots such as the SCR003-400 are perfect for tiny to medium weights. This makes them extremely useful for repetitive and delicate tasks. Faster production cycles and higher-quality products are made possible by their accuracy and adaptability, which are revolutionizing robotics in manufacturing.

The Effect of SCARA robots on Production Effectiveness

SCARA robots are well suited for robotics in manufacturing because of their remarkable accuracy in fast, repeated actions. The electronics, pharmaceutical, and automotive sectors are good fits for the EVS SCR003-400, which is designed to automate processes like assembling, selecting, and placement. This SCARA robot can perform intricate motions rapidly while retaining high levels of precision, directly increasing productivity in robotics in manufacturing thanks to its small design and high-speed operation.

Automating repetitive activities using SCARA robots reduces mistakes significantly by doing away with the requirement for human interaction. This leads to consistent product quality and reduced production costs—two critical outcomes for businesses vying for customers in the current global marketplace. When SCARA robots are added to manufacturing lines, things move more quickly and firms are able to fulfill deadlines without compromising efficiency or quality.

Precision and Speed of SCARA robots

Speed and accuracy play a crucial role in determining how efficiently production processes work in robotics in manufacturing. The SCR003-400 is one of the SCARA robots that is made to provide the ideal balance of both. These robots work well at high-speed, extremely accurate activities like soldering or applying adhesives in the electronics manufacturing industry. A key benefit of robotics in manufacturing is the SCR003-400’s 4-axis architecture, which allows it to move with great accuracy and quick cycle times.

The SCR003-400 is extremely adaptable to a variety of industrial applications because of its tiny construction, which enables it to fit into small locations on production lines. Its capacity to repeat difficult jobs reliably, cutting waste and raising overall product quality, adds to its accuracy. Businesses may increase productivity and shorten cycle times without sacrificing quality by using SCARA robots, such as the SCR003-400, into their manufacturing operations.

Robotics in manufacturing: Adaptability and Flexibility

The SCR003-400 offers producers a flexible substitute since it can be quickly switched between various jobs. Minimal modification is required for the several jobs that SCARA robots are meant to do, such as assembly, material handling, and packing. In businesses where product lines change often, this adaptability is essential to enable producers to swiftly respond to shifting consumer expectations.

When accuracy and speed are required concurrently, as in the case of assembling small, fragile parts, the SCR003-400 is an especially helpful instrument. The robot’s movable limbs enable the customization of its motions to meet various industrial demands. Because of their versatility, SCARA robots are an essential part of contemporary robotics in manufacturing, allowing businesses to grow efficiently and rapidly.

Efficiency in terms of cost and ROI

Since SCARA robots like the SCR003-400 save labor costs and boost operational efficiency, investing in them yields a large return on investment. Assembly and material handling are two labor-intensive jobs that robotics in manufacturing may completely automate, freeing up human labor for more challenging jobs. Manufacturers may save a lot of money on operational costs and enhance productivity by using less physical labor.

Additionally, SCARA robots reduce mistakes, which lowers the number of faulty goods and material waste. This results in reduced expenses for trash and rework as well as more consistent product quality. Because SCARA robots can operate continuously without becoming weary, production lines may run continuously throughout the day, increasing productivity and profitability in the robotics in manufacturing business.

In conclusion

One exceptional high-performance SCARA robot from EVS that may boost output, reduce expenses, and improve product quality is the SCR003-400. Because of their versatility and capacity to do difficult jobs fast and precisely, SCARA robots are a crucial component of contemporary industrial systems. The future of production for industries worldwide will be determined by the increasing role that SCARA robots play in robotics in manufacturing as automation technologies improve.