Choosing the right low cost collaborative robot can revolutionize your business. These low cost collaborative robots provide affordable automation solutions, enhancing productivity while minimizing errors. With advanced safety features, they enable smooth human-robot collaboration. To achieve the best ROI, consider aspects such as cost, functionality, and safety. Knowing how to select the ideal low cost collaborative robot ensures sustained success and flexibility.

Key Takeaways

- Collaborative robots (cobots) enhance productivity and safety by working alongside humans without the need for extensive safety barriers, making them ideal for various industries.

- When choosing a cobot, evaluate its payload capacity and reach to ensure it meets your specific operational needs, balancing flexibility with the tasks at hand.

- Investing in proper training and support for your cobot can significantly boost productivity and employee confidence, leading to a smoother integration into your workflows.

Understanding Collaborative Robots

What Makes Collaborative Robots Unique?

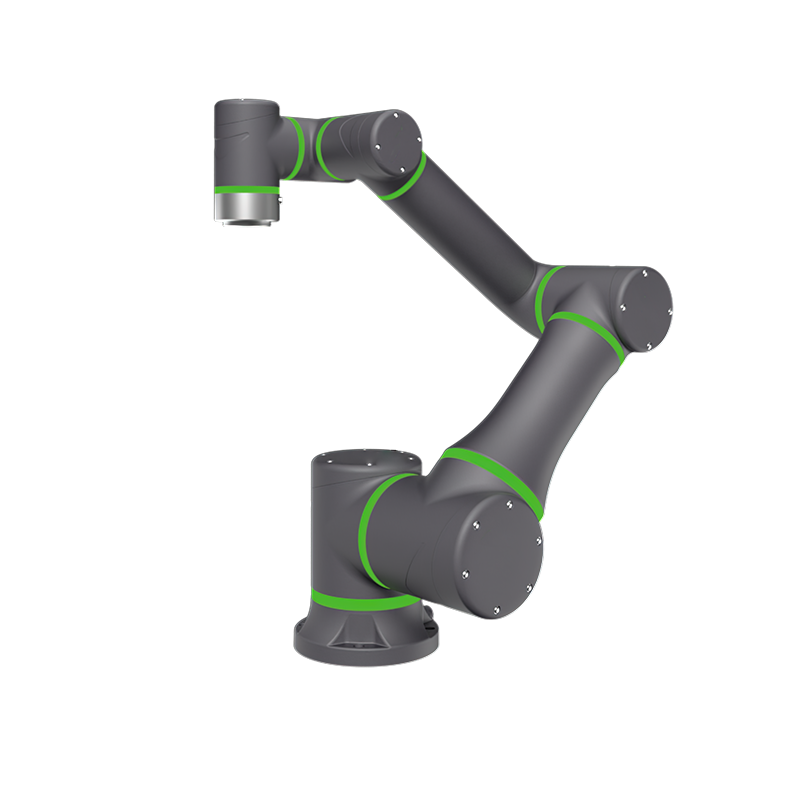

Collaborative robots, or cobots, stand out due to their design and functionality. Unlike traditional industrial robots, cobots are smaller, lighter, and more flexible. They can work alongside humans without requiring safety cages. Built-in sensors and force/torque controls ensure safe operation by halting movement when resistance is detected. This makes cobots ideal for environments where human-robot interaction is essential.

| Feature | Collaborative Robots (Cobots) | Traditional Industrial Robots |

|---|---|---|

| Size | Small and lightweight, mobile multitaskers | Large and powerful, fixed in place |

| Safety | Built-in controls for safe operation, minimal fencing | Require safety cages due to high speed |

| Flexibility | Can be easily moved and programmed on-site | Limited flexibility, fixed tasks |

| Speed | Operate at lower speeds (1 m/s or less) | Can move as fast as 3 m/s or more |

| Payload Capacity | Generally between 3 and 16 kg, some up to 35 kg | Designed for heavy lifting |

| Interaction with Humans | Designed to work alongside humans | Typically isolated from human workers |

Cobots also feature intuitive interfaces, allowing you to program them with ease. Many models even support hand-guided programming, making them accessible for businesses of all sizes.

Benefits of Using Cobots in Business

Cobots offer affordable automation solutions that enhance productivity and safety. Their lightweight and mobile design allows you to move them across your manufacturing floor effortlessly. This flexibility enables quick task switching, reducing downtime.

Safety is another key benefit. Cobots operate safely alongside humans, eliminating the need for extensive safety barriers. Sensors detect resistance and stop operations to prevent injuries or product damage. This creates a safer work environment for your team.

Cobots also simplify robotic automation. Their user-friendly interfaces and quick installation process lower the barriers to entry for small and medium-sized businesses. By automating tasks like assembly, packaging, and material handling, cobots improve efficiency and consistency.

Applications of Cobots Across Industries

Cobots are transforming industries by automating tasks that require precision and consistency. In manufacturing, they handle assembly, packaging, and raw material management. Electronics companies use cobots for assembling circuit boards and wiring.

In logistics and warehousing, cobots excel at sorting, picking, and packing goods. Healthcare facilities rely on them for lab testing and patient intake. Metal fabrication industries use cobots for welding, CNC operations, and machine tending.

Cobots also play a significant role in plastics and polymers, where they assist with palletizing, polishing, and 3D printing. Their versatility makes them a valuable addition to any industry seeking efficient automation solutions.

Key Factors for Choosing a Low-Cost Collaborative Robot

Evaluating Payload and Reach

When selecting a cobot, you must evaluate its payload and reach. The payload refers to the maximum weight the cobot can handle, while the reach is the distance its arm can extend. Cobots typically support payloads of up to 20 kg, making them ideal for lighter tasks. However, if your production line involves heavy parts, traditional robots may perform better.

Keep in mind that a longer reach often reduces payload capacity. This trade-off occurs because extended arms place more force on the cobot’s joints. Consider your workspace layout and the size of the items being handled to ensure the cobot fits your needs.

Importance of Safety Features

Enhanced safety is a hallmark of collaborative robots. Look for cobots with certifications like ANSI B56.5 or RIA 15.08. These standards ensure the cobot meets strict safety requirements. Cobots are designed to stop safely upon contact with humans, minimizing risks in shared workspaces. Conducting a third-party risk assessment can help identify additional safety measures.

Ease of Use and Programming Simplicity

User-friendly programming is essential for cost-effective automation. Many cobots feature teach pendants, which allow you to guide the robot manually. Graphical user interfaces with drag-and-drop functionality make programming accessible, even for beginners. Some cobots also support lead-through programming, where you physically move the arm through tasks. These features reduce setup time and training costs.

Budget and Cost Considerations

Pricing plays a significant role in choosing a low cost collaborative robot. Cobots typically range from $8,000 to $20,000, making them more affordable than traditional robots, which can cost tens of thousands of dollars. Evaluate your budget and consider the long-term savings cobots offer through increased productivity and reduced labor costs.

Calculating ROI for Collaborative Robots

Measuring Productivity Improvements

To calculate ROI, you need to assess how cobots enhance productivity. Cobots streamline operations by automating tasks that require precision and consistency. Metrics like cycle time and cycles completed help you measure performance. For example, cycle time tracks how long it takes a cobot to complete a task compared to manual labor. A shorter cycle time indicates increased productivity.

Cobots also reduce downtime. Their ability to operate 24/7 ensures consistent output, even during non-working hours. Utilization rates, which measure the percentage of time a cobot is actively working, provide insights into efficiency. High utilization rates reflect better performance and faster ROI.

Assessing Labor Cost Savings

Cobots offer cost-effective solutions by minimizing labor expenses. They can replace repetitive manual tasks, allowing you to reallocate workers to higher-value roles. To estimate savings, calculate the number of employees a cobot replaces and their annual salaries, including benefits.

Cobots excel in industries like electronics and logistics, where they handle tasks such as assembly and sorting. Their versatility allows quick reprogramming for different jobs, making them ideal for small-batch production. By operating continuously, cobots maximize output while reducing reliance on overtime or additional shifts.

Evaluating Quality and Consistency Gains

Cobots improve quality by delivering consistent performance. Unlike humans, cobots don’t experience fatigue, which reduces errors in repetitive tasks. Metrics like yield and scrap costs help you evaluate these improvements. A higher yield and fewer defects indicate better quality and lower production costs.

Cobots also enhance consistency in manufacturing processes. For instance, in medical device manufacturing, cobots ensure precise assembly, leading to improved quality. This consistency boosts customer satisfaction and strengthens your brand reputation.

Tip: When calculating ROI, consider the total cost of ownership, including initial investment, installation, training, and maintenance. These factors provide a complete picture of your cobot’s long-term value.

Ensuring Integration and Compatibility

Compatibility with Existing Systems

Ensuring that a cobot integrates seamlessly with your current systems is essential for smooth operations. Start by evaluating your workspace design and layout. A well-organized workstation minimizes collision risks and enhances efficiency. Clearly define areas for human workers and cobots to ensure safe collaboration.

Next, assess the compatibility of the cobot with your existing equipment. Check if the cobot’s payload capacity and communication protocols align with your system requirements. For example, a cobot used in manufacturing should easily connect with your production line software. User-friendly programming interfaces also simplify integration, reducing setup time and costs.

Finally, conduct a thorough risk assessment. This ensures compliance with safety standards and identifies potential hazards. Adding safety components, such as sensors or emergency stop buttons, further protects workers and equipment.

Scalability for Future Automation Needs

When planning for future automation, focus on scalability. Cobots excel in high-mix, low-volume production environments, making them ideal for businesses with evolving needs. Begin by identifying tasks that benefit most from automation, such as repetitive or time-consuming processes.

Implement cobots gradually. Start with simple tasks to allow your team to adapt and learn. This approach minimizes disruptions and builds confidence in the technology. Involve employees in the process to address concerns and foster acceptance. Their input can help identify additional opportunities for automation.

As your business grows, cobots can adapt to new challenges. Their flexibility allows you to reprogram them for different tasks, ensuring long-term value.

Training and Support for Cobots

Proper training ensures you maximize the benefits of your cobot. Many manufacturers offer a range of training options to suit your needs.

| Training Type | Description |

|---|---|

| Academy Service | Level up your automation with robotics training sessions. |

| Video Tutorials | Access a variety of instructional videos. |

| Online Sessions | Participate in training sessions via the internet. |

| Onsite Sessions | Receive training directly at your location. |

| Customer Service | Get dedicated support to optimize Dobot robots. |

| FAQ | Common questions answered here. |

Choose the training method that works best for your team. Onsite sessions provide hands-on experience, while online resources offer flexibility. Manufacturers also provide ongoing support, ensuring your cobot operates efficiently.

Tip: Investing in training not only improves productivity but also boosts employee confidence in using cobots effectively.

Overcoming Challenges with Cobots

Addressing Employee Concerns and Resistance

Introducing cobots into your workplace can raise concerns among employees. Some may worry about job security or feel uncertain about working alongside robots. Address these concerns by focusing on the benefits cobots bring to your team:

- Conduct an in-depth system audit to identify areas where cobots can complement human efforts.

- Collaborate with experienced robotics companies to ensure smooth integration into workflows.

- Highlight how cobots reduce repetitive tasks, improve safety, and create opportunities for employees to develop new skills.

Cobots enhance job satisfaction by taking over strenuous tasks, reducing workplace injuries, and increasing retention rates. Employees can shift to higher-value roles, which often lead to better pay and career growth. Open communication and training sessions can help your team embrace this technology with confidence.

Tip: Involve employees in the planning process to foster a sense of ownership and reduce resistance.

Managing Maintenance and Downtime

Proper maintenance ensures your cobot operates efficiently and minimizes downtime. Develop a strict maintenance schedule to keep your cobot in optimal condition. Regularly inspect and maintain components like the End of Arm Tooling (EOAT) and sensors.

Here’s a checklist to guide your maintenance routine:

- Grease joints and gears as specified in the manual.

- Inspect and clean the robot arm, wiring, and base.

- Replace filters on cooling fans and vents.

- Monitor sensors for real-time data on temperature and tolerances.

- Listen for unusual sounds during operation to detect mechanical issues early.

Note: A well-maintained cobot reduces unplanned downtime, saving you time and money.

Ensuring Compliance with Regulations

Deploying cobots requires adherence to safety standards. Conduct a risk assessment to ensure compliance with regulations like ISO 10218-1 and ISO/TS 15066. These standards define safe collaborative robot applications.

Cobots typically don’t need additional safety equipment if designed properly. However, short barriers or safety sensors can enhance protection in shared workspaces. Consult your cobot supplier to confirm safe speed ratings and ensure compliance with standards like ANSI B56.5 and RIA 15.08.

Tip: Partnering with a trusted cobot manufacturer simplifies compliance and ensures your cobot meets all safety requirements.

Selecting the best low cost collaborative robot involves several essential steps. Start by identifying your specific needs and researching manufacturers. Factor in operational costs, installation expenses, and potential ROI. Align the cobot’s features with your business goals by evaluating tasks suitable for automation and optimizing workflows. Cobots offer long-term benefits like 24/7 operation, reduced labor costs, and improved efficiency. By making informed decisions, you can achieve sustainable growth and maximize your investment.

FAQ

What industries benefit the most from using cobots?

Cobots excel in manufacturing, logistics, healthcare, and electronics. They handle tasks like assembly, packaging, welding, and lab testing with precision and efficiency.

How long does it take to set up a cobot?

Most cobots take a few hours to a day for setup. User-friendly programming and plug-and-play features simplify the process.

Can cobots replace human workers entirely?

Cobots complement human workers by automating repetitive tasks. They free up employees for higher-value roles, improving productivity without eliminating jobs.