Welding robots have become essential in the rapidly developing field of industrial automation to increase production uniformity and efficiency. These robots become much more powerful when paired with a welding turntable. Robotic welding machines automate the operation, improving accuracy and lowering human error. The workpiece may revolve smoothly thanks to welding turntable integration, allowing the robot to access previously unattainable difficult angles. The whole quality of the welding process is improved by this synergy, which also greatly increases productivity.

Welding turntables’ Significance in Industrial Automation

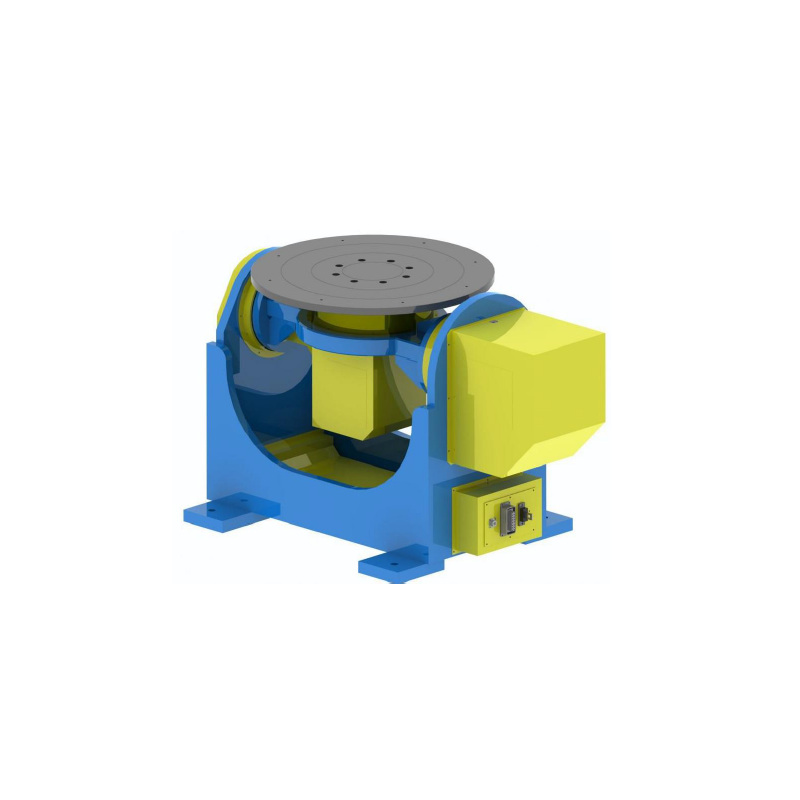

Large workpieces may rotate smoothly with the help of the EVS Single-Axis Head and Tail Stock Positioner, enabling welding robots to weld at intricate angles without sacrificing accuracy. Welding processes that once needed several stages may be automated by operators using welding turntables. This greatly shortens the manufacturing time while simultaneously increasing the weld quality. Welding robots can operate on pieces with complex geometries because to the improved control provided by welding turntables, producing high-quality results in a much shorter amount of time.

Better Accuracy and Less Downtime

While cutting downtime, the usage of welding turntables in conjunction with welding robots greatly improves welding accuracy. For example, multi-axis movement is made possible by the sophisticated design of EVS’s Two-Axis Servo Positioner, which is essential for reducing mistakes brought on by human handling. The welding turntable‘s automation guarantees continuous operation, cutting down on production delays and increasing efficiency.

When welding turntables and robots are used together, intricate, multi-sided welds may be completed with the utmost accuracy and precision. Downtime is reduced by automating the procedure and doing away with the need for manual repositioning, guaranteeing continuous production cycles and a greater rate of output.

Improving Adjustability in Welding Processes

The flexibility that combining welding robots with a welding turntable offers to production processes is one of the most significant benefits. The welding turntable guarantees that the workpiece is precisely positioned for each weld, regardless of the size of the assignment, from small components to massive assemblies. The Single-Axis Head and Tail Stock Positioner, among other welding positioners from EVS, offers flexible solutions that can handle a variety of part sizes and forms.

With this combination, producers may use a single robotic system to do several welding processes. The welding robots‘ versatility is increased by the welding turntable, which lets them do a variety of jobs including spot, seam, and tack welding. For sectors that deal with a variety of materials and designs, this flexibility is essential because it enables quick production modifications to satisfy consumer demand.

Enhanced Efficiency and Decreased Labor Expenses

The combination of welding robots and welding turntables directly affects productivity by automating the welding process from start to finish. For example, dual-axis rotation is provided by the Platform Two-Axis Servo Positioner from EVS, which allows welding robots to do complex welding jobs without the need for manual corrections.

Businesses may drastically save labor expenses and human error by limiting the amount of time that employees spend on repetitive welding operations. In addition to increasing uniformity and speed of production, this high level of automation enables organizations to satisfy strong demand without compromising quality. Purchasing welding robots and welding turntables is an affordable way to lower overall operating costs while increasing welding precision.

Welding Automation’s Future

The use of welding robots and welding turntables together will become more and more important in contemporary production as industries progress toward higher automation. These methods increase overall production efficiency while enabling producers to produce accurate, fine-quality welds on intricate geometries. Achieving these objectives depends on the sophisticated welding positioners made by EVS, such as the Single-Axis and Two-Axis Servo Positioners. Businesses hoping to stay competitive in a constantly shifting industry will need to use these cutting edge technology. They will be able to reduce expenses and boost productivity all while upholding excellent manufacturing standards.

In summary

In conclusion, producers may greatly increase production, accuracy, and efficiency by combining welding robots with a welding turntable. The Single-Axis and Two-Axis Servo Positioners from EVS are products that show how a welding turntable may improve the capabilities of welding robots, resulting in increased welding accuracy and operational flexibility. Businesses can handle the increasing demands of contemporary production while maintaining the highest standards of quality by investing in this cutting-edge technology. Automation of welding robots and welding turntables is a prerequisite for production facilities that wish to remain at the forefront of industrial automation.