Introduction to Robotic Welding

Welding robot use is becoming more and more common in both larger manufacturing plants and smaller, project-based workshops as the twenty-first century goes on. This is not a fad, but rather a fundamental shift in the way that welding tasks are approached and completed; the initial cost of purchasing welding robots may seem high, but the remarkable increases in business performance that We bring quickly offset this cost.

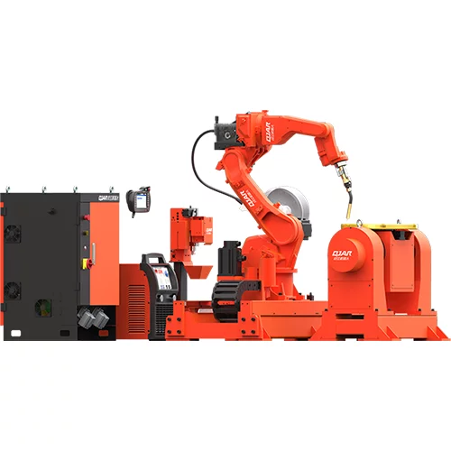

In the spotlight of this evolution is a notable product: the 4kg Payload 1410.5mm Reaching Distance Welding Robot QJRH4-1A. This welding robot, known for its dependability and great value for money, is a game-changer in the welding business. It has characteristics like hollow structural arms and wrists, a built-in welding cable, and the capacity to work in confined places. Its lightweight, compact structure, coupled with a protective cover, makes it ideal for harsh environments. With its large workspace, fast running speed, and high repeat positioning accuracy, it stands as a testament to the capabilities of modern welding robots.

Benefits of Robotic Welding

Consistency and Quality of Welds

The unparalleled consistency and quality of welds produced by welding robots, such as the QJRH4-1A, is one of the strongest arguments for enterprises to utilize them. The QJRH4-1A’s performance is dependent on the caliber of the materials it uses and the workflow’s efficiency. Once these elements are systematized, welding robots can consistently outperform even the most experienced human welders in terms of quality and efficiency.

Enhanced Productivity and Throughput

Welding robots transform the concept of an 8-hour workday by enabling 24-hour operations. This continuous workflow is not just about working longer hours; it’s about working smarter. Robots like the QJRH4-1A streamline key processes, reduce the manual labor required, and significantly lower error rates. This shift allows human workers to focus on higher-level tasks and challenges, enhancing overall productivity and throughput.

Reduction in Waste and Rework

Overwelding has long been a significant source of waste in welding projects. Welding robots address this issue head-on with their ability to follow ultra-precise specifications, leading to lower metal filler costs and the elimination of unnecessary, oversized weld beads. The QJRH4-1A is exemplary in this regard, ensuring minimal waste and rework in welding tasks.

Reduced Post-Weld Cleanup

Less waste naturally translates to faster cleanup, a benefit that cannot be overstated in a busy welding environment. With welding robots like the QJRH4-1A, the reduction in weld spattering means less downtime between projects. The clean, neat seams produced meet even the most exacting standards set by clients, further reducing the need for post-weld cleanup.

Accelerated Market Access

The precision and control offered by welding robots are unparalleled. Systems like the QJRH4-1A can be precisely calibrated for various projects, no matter how unique or innovative We may be. Due to their ability to quickly bring items to market and compete with larger industrial giants, smaller shops have an advantage over larger ones.

Market Context and Cost Considerations

Despite their many benefits, the niche use of welding robots is partly due to the high cost of comprehensive automated systems. However, this should not deter potential adopters. The initial investment in a robot like the QJRH4-1A is offset by the significant productivity gains it offers. Early adopters of welding robots stand to lead in productivity, setting a pace that others in the manufacturing industry will strive to match.

Conclusion and Further Learning

The advantages of welding robots, particularly models like the QJRH4-1A, are clear and manifold. It is clear that those that embrace these technical breakthroughs will have a bright future as we continue to explore the potential of automated welding. We offer consistency, efficiency, decreased waste, and the agility to respond to changing market demands.

A robotic welding webinar featuring specialists who will answer questions and give insights about this quickly developing sector is one of the options available for individuals eager to learn more about the world of welding robots and welding positioners.

In conclusion, the integration of welding robots and welding positioners into the welding industry marks a significant step forward. The QJRH4-1A is a prime example of how these technologies are not just changing the way we weld but revolutionizing the entire manufacturing landscape.