Introduction

Within the domain of contemporary manufacturing, welding procedures serve as a fundamental element of high-quality production, guaranteeing the longevity and soundness of essential infrastructure as well as commonplace consumer products. In the pursuit of increased productivity and efficiency, technology arises as a crucial ally. Welding positioners and welding turntables, among these technological advancements, are transforming the welding process by providing throughput improvements, safety, and precision that are unmatched. This innovation is exemplified by the Single Axis Welding Positioner EVS-SWP-ZW-500/800/1200, which combines functionality and advanced design to increase the efficiency of the welding process to unprecedented levels.

Understanding Welding Positioners

The Essence of Welding Positioners

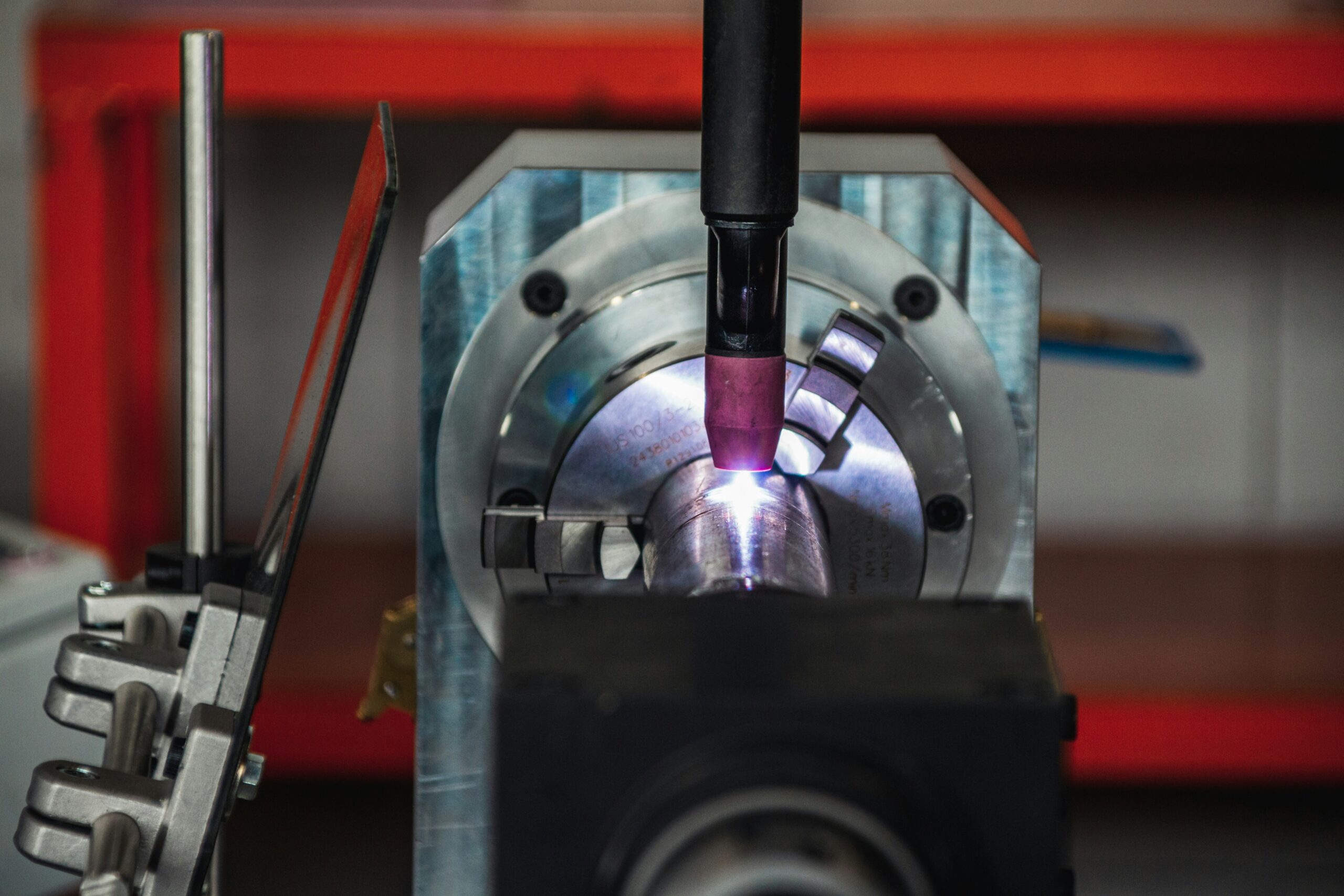

Positioners for welding are crucial for the automation and optimization of welding processes. These apparatuses facilitate the manipulation of the workpiece, guaranteeing that the welder or welding automaton is in an ideal position of alignment and accessibility. The primary objective of a welding positioner is to optimize weld quality, decrease reliance on manual labor, and streamline workpiece positioning processes—thereby substantially bolstering safety and productivity in the workplace.

Spotlight on the EVS-SWP-ZW Series

The Single Axis Welding Positioner EVS-SWP-ZW series is widely regarded as the epitome of welding technology. These positioners are designed to accommodate loads varying from 500kg to 1200kg and provide repeat positioning accuracies between ±0.10mm and ±0.15mm. As a result, they are suitable for an extensive variety of industrial applications. With rated gyration rates of up to 70°/S, this series is a formidable asset to any modern manufacturing arsenal, capable of meeting the stringent requirements of sectors including furniture, food and beverage, and electronics. accommodating the high demands of industries such as furniture, food and beverage, and electronics.

The EVS-SWP-ZW series is engineered for high-speed and high-precision palletizing, picking, packaging, and handling tasks. Its robust design, featuring a high-quality gyration main spindle case, tail case, and welding gyration frame, ensures durability and stability. The incorporation of an AC servo motor and RV precise reducer guarantees superior gyration stability and positioning accuracy, critical for achieving flawless welds in high-throughput production environments.

The Role of Welding Turntables in Production

Welding Turntables: The Rotary Foundation

Welding turntables serve as the rotary foundation for welding operations, ensuring that the workpiece rotates in a consistent and manageable manner. The aforementioned rotational motion enables uninterrupted welding, thereby producing uniform, superior-quality welds that encircle the complete perimeter of the workpiece. In applications requiring circumferential welds or where access to all sides of the workpiece is essential for comprehensive welding coverage, welding turntables are particularly advantageous.

Integration with Welding Positioners

The correlation between welding positioners and welding turntables is of the utmost importance. Upon integration, these instruments provide an all-encompassing resolution to welding obstacles, empowering both personnel and automated systems to execute welds with unparalleled accuracy and effectiveness. The seamless rotation of the turntable, in conjunction with the positioner’s capacity to incline and angle the workpiece, guarantees that each weld is easily accessible and performed under ideal circumstances. The integration in question plays a critical role in optimizing production workflows, substantially decreasing cycle times, and enhancing the welding output’s overall quality.

Maximizing Efficiency with the EVS-SWP-ZW Series

Leveraging Advanced Features

The EVS-SWP-ZW series welding positioners are more than just a tool; they are a gateway to unparalleled efficiency in welding operations. With their robust design and advanced technical specifications, these positioners facilitate the handling of heavy loads with precise control over movement. To fully harness their potential, operators should leverage the positioner’s high-speed gyration and repeat positioning accuracy. This ensures that workpieces are consistently positioned at the ideal angle and rotation speed for optimal welding, minimizing downtime and maximizing throughput.

Operational Best Practices

Achieving maximum efficiency with the EVS-SWP-ZW series requires adherence to best practices in setup, operation, and maintenance. Properly calibrating the positioner for specific tasks, regularly checking the conductive system for integrity, and utilizing the protective cover to safeguard the equipment are all critical steps. Additionally, operators should be trained to optimize the use of the AC servo motor and RV precise reducer, ensuring smooth and stable gyration at all times.

Selection Guide for Welding Positioners and Turntables

Assessing Application Needs

Determining which welding positioner or gimbal is ideal for a given application requires a comprehensive evaluation. The complexity of the welding duties, the weight and dimensions of the workpieces, and the required precision and speed should all be taken into account. The EVS-SWP-ZW series is suitable for a vast array of applications due to its variable load capacities and gyration velocities. When performing tasks that necessitate significant rotation or precise positioning angles, the addition of a turntable to a welding positioner can significantly improve adaptability and productivity.

Matching Specifications to Requirements

Ensure that the specifications of the welding positioner or gimbal you choose correspond to your operational needs. Ideal for heavy-duty applications, the EVS-SWP-ZW-1200 model features an expansive gyration radius and a load capacity of 1200kg. In the context of more intricate or exacting duties, the EVS-SWP-ZW-500 might provide the essential dexterity and precision. When evaluating the equipment’s suitability for your production line, it is crucial to take into account the utmost angle of gyration, standard radius of gyration, and rated speed.

Integrating Welding Positioners into Existing Workflows

Seamless Integration Strategies

The successful incorporation of welding positioners and turntables into established manufacturing workflows necessitates the implementation of strategic planning. In order to sustain ongoing operations, ascertain the optimal method for integrating the newly acquired equipment into the architectural framework of the production area. Irrespective of the welding processes in operation, verify that the welding positioners and turntables are compatible with the existing welding apparatus and automation systems.

Realizing Return on Investment

Welding positioners and turntables, like those in the EVS-SWP-ZW series, represent a sizable investment in the effectiveness and caliber of welding procedures. Rapid realization of the return on this investment is achievable via increased production throughput, decreased labor expenses, and reduced rework and waste. Ongoing training for operators and consistent equipment maintenance are imperative for the long-term sustainability of these advantages.

Conclusion

Welding platforms and positioners are essential components in contemporary manufacturing, providing a means to enhance the effectiveness, accuracy, and security of welding procedures. The EVS-SWP-ZW series serves as a prime illustration of the potential that these technologies possess, enabling producers to enhance their manufacturing processes. Through meticulous equipment selection, strategic utilization of its sophisticated functionalities, and seamless integration into preexisting operational processes, manufacturers can attain substantial enhancements in both output volume and product excellence, thereby fortifying their competitive advantage in the marketplace.