Source: www.roboticstomorrow.com

In the world of business today, you find that certain tasks are being taken over by machines and technology that make the processes easier. However, most people don’t understand what all that is about. This makes them shy away from investing in automation technologies. To change this, the best thing to do is to work toward learning more about industrial automation and why it is so essential in different industries.

What is Industrial Automation?

Source: drysys.com.au

Industrial automation is the use of different technologies and machinery programmed to get certain processes done without any human interference. Over the years, industrial automation has been used to replace manual labor to increase productivity and efficiency.

Industrial automation features the use of a variety of innovations meant to make work easier and get it done faster. Automation negates the need for human involvement by creating programmable commands suitable for the machinery you are working with. It involves different hierarchies during operations and also features different types of automation.

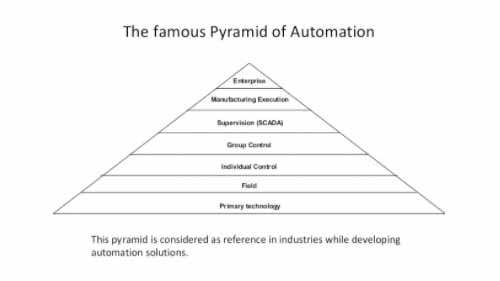

Hierarchies in Industrial Automation

Source: www.slideshare.net

When it comes to industrial automation, there are a lot of processes involved to ensure that the products and services are effective. This is done with the use of different hierarchies including:

Field Level

The field level involves the use of field devices like actuators and sensors. It is the lowest level of the hierarchy involved in industrial automation. This involves the transfer of data processes from one section to another. The actuators are used to control the process parameters while the sensors convert these parameters into actionable steps.

Control Level

This consists of automation devices like CNC machines and PLCs among others. For this to function, they acquire process parameters from different sensors. Doing this results in the different actions achieved by the technology in use.

Programmable Logic Controllers (PLC)

These particular controllers are featured when dealing with industrial robust machines and heavy machinery. It involves the use of different modules that allow it to be more effective. These communication modules make the sensors work better and receive commands with ease.

Supervising and Production Control Level

This works more like the human intervention efforts witnessed to ensure that all processes are being done right. These controllers work to ensure that industrial automation machinery being used works as it should.

Information or Enterprise Level

The information level is where the industrial automation systems are controlled from. This Level involves all the processes that help the automation systems run smoothly. From production planning to sales and customer acquisition, the information level is essential. For his, you need to have the necessary communication networks in place. This will ensure that the efforts you put into your automation processes do pay off.

Types of Industrial Automation Systems

Source: electronicsmaker.com

Given that different industries will undertake different automation tasks, getting to learn more about the types you are working with is essential. Some of them include:

Fixed or Hard Automation

When you think of repetitive tasks that are undertaken in a business, this automation system is designed to address them. Using this automation system allows you to increase production rates in your business. The only downside about this is the fact that once it is set in motion, you don’t have the freedom to change your designs. If your dealing with products that don’t need too much manipulation, then this is the right system for you.

Programmable Automation

Like the fixed system, the programmable automation system is also designed to address different repetitive tasks. However, the significant difference is that with this system, you have the freedom to tweak and make changes to your designs. This is made possible by the programmable controls that come with the system to ensure that it meets your specific needs. This process is mostly featured in the batch production processes where the company produces medium to high volumes of products. This is a great system especially if you plan to work on different things that will require different configurations.

Flexible or Soft Automation

If you need a system that is more reliable especially when it comes to reconfigurations when it comes to working with different products, this is the system for you. It offers more flexibility in that you can easily manipulate the controls in minutes by entering the necessary codes. This makes this system the most preferred option when it comes to production processes. Working with the flexible automation system allows the manufacturer to work on their products simultaneously. This reduces the hassle of having to deal with different processes each time you want to change products or their designs.

Why Industrial Automation is Important

Source: www.plantautomation-technology.com

Now that you have all the information on what industrial automation is, the next step is to figure out why it’s important. This will let you determine whether it is worth the investment or you’d rather work without it. Some of the most significant factors associated with industrial automation include:

Increased Productivity

When it comes to manufacturing and business in general, productivity is an important aspect that you need to pay close attention to. With industrial automation, the best part is that these systems can work around the clock. This means that you can depend on working with productions taking place 24/7 for 365 days. This factor increases productivity greatly and leads to more production in the process.

Enhanced Quality

With automation systems, you are assured of 100% guaranteed quality. This is dependent on the materials you use and the configurations you apply. Needless to say, these automation processes are designed to carry out orders as instructed by the controls. With this in mind, you can rest easy that there will not be any mistakes during production. The reduction of mistakes allows you to achieve quality on all products produced.

Flexibility

Automation systems allow the user to change processes by just changing the configurations involved. However, in the traditional production processes, you’d have to take more than a few hours or days of training before productions commence. This improvement provides a lot of flexibility for the manufacturers.

Increased Consistency

Consistency in the quality of products, design, and development is something you need to ensure you have in check. This works best by relying on automation systems that ensure all products are made with the same specifications. This can be hard when working with human labor where mistakes are bound to occur. With automation systems, you’ll be in a great place knowing your products maintain the same quality and consistency.

Saves on Costs

With industrial automation in the picture, the need to hire a lot of workers to complete your production requirements is greatly reduced. This helps you reduce costs that would otherwise be spent on salaries and other logistical aspects. It will save on costs incurred when mistakes are made during production.

Reduces Routine Check-in

The use of industrial automation in your business, helps you avoid routine check-ins that occur when working with physical labor. Given that with automation you are assured of quality and consistency, you won’t need to have consistent supervision of the production and packing processes.

Raises the Levels of Safety

When it comes to manufacturing, there’s a great reliance on heavy machinery and other equipment. With this, you find that the risk of injury increases significantly especially when working with human labor. However, with automation, you won’t need to worry about any of that. This raises the level of safety and reduces your exposure to any liabilities and damage.

Conclusion

Industrial automation is a great investment in any industry your business is in. It works great to ensure that all processes are carried out as they should. The benefits of implementing these systems speak for themselves. This goes to show that working with this option will allow you to enjoy great benefits in your business.

One Response

I liked it the most when you shared that automation systems allow for more production in the process. My friend wants to install an automation system in their facility. I should advise him to turn to an expert in industrial automation system installation to ensure quality work.